Method for measuring porosity in piping development process

A technology of development process and porosity, applied in the direction of measurement device, permeability/surface area analysis, suspension and porous material analysis, etc., can solve the problem of not being able to accurately measure piping and restrict the in-depth study of piping development mechanism, etc., to achieve The effect of deepening understanding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

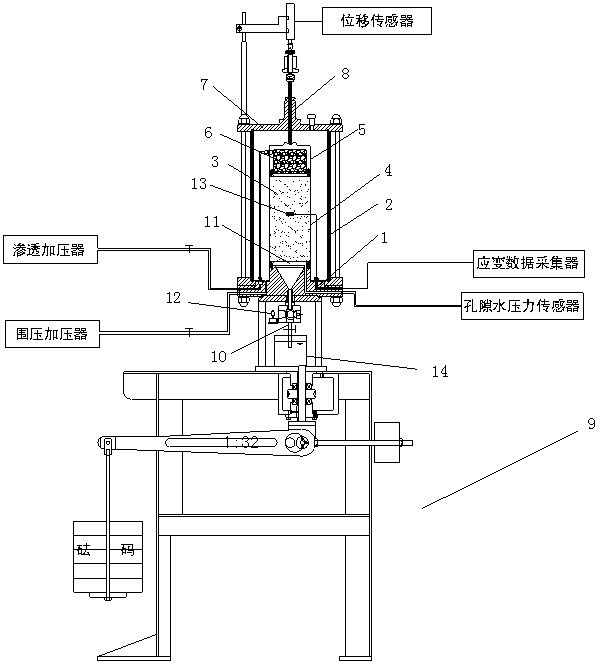

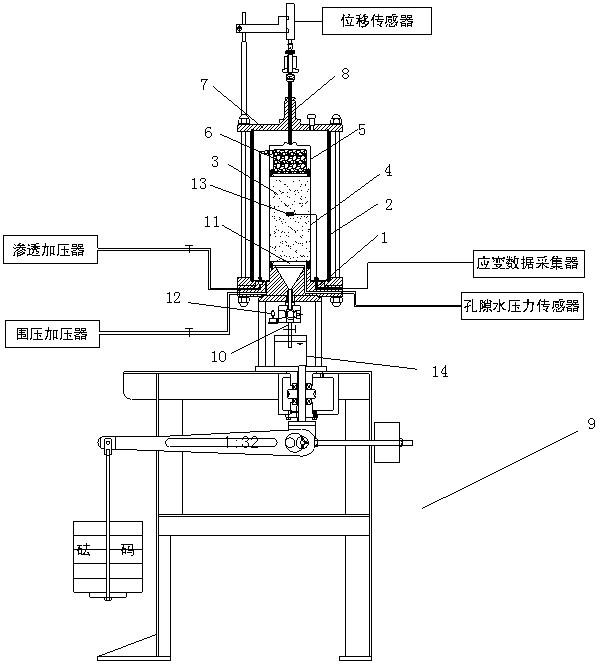

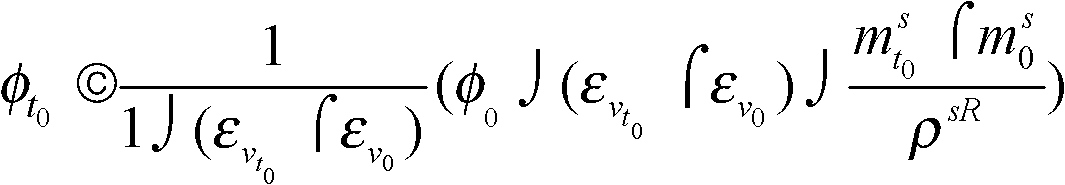

[0022] Embodiment: the present invention utilizes as figure 1 The shown seepage-erosion stress-coupled piping test device is used to measure the porosity of soil during the development of piping.

[0023] The test method of seepage erosion stress coupled piping test device, the steps are as follows:

[0024] (1) Preparation and installation of samples. First, according to the requirements of dry density and water content, a special split mold is used to prepare the sample, and the outer surface of the sample is tightly wrapped with a heat-shrinkable tube. Secondly, place a porous steel plate with a diameter of 2mm on the base (the porous steel plate is mainly used to separate coarse and fine materials, this test assumes that the particle size of the movable fine particles is less than 2mm, that is, in the test, only fine particles with a particle size of less than 2mm can flow out of the test sample), fix the sample on the base of the instrument, and tighten the screws. Fin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com