Optical-fibre composite low-voltage cable

A low-voltage cable and optical fiber composite technology, applied in the field of power cables, can solve the problem of wasting cable resources and pipeline resources, and achieve the effect of saving cable resources and pipeline resources, light weight, and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

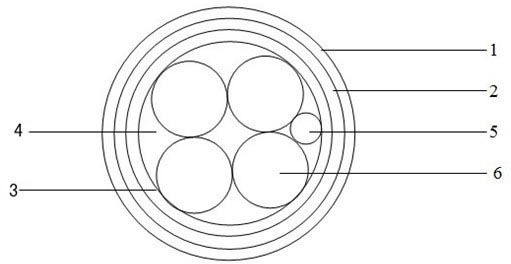

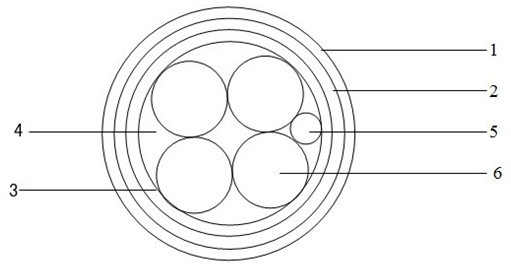

[0016] Such as figure 1 As shown, an optical fiber composite low-voltage cable according to the present invention includes a cable core, the gap in the cable core is filled with a filling layer 4, and a tape layer 3, an armor layer 2 and a sheathing layer are sequentially wound concentrically outside the cable core. The jacket layer 1; the cable core is formed by twisting the insulated core 6 of the low-voltage power cable and the optical cable 5 concentrically.

[0017] The cable core of the present invention is composed of a low-voltage power cable insulated core and an optical cable with a twisted core structure of 2 cores + 1, 3 cores + 1 or 4 cores + 1. Metal layer twisted filled optical cable, non-metallic central tube dry type optical cable or non-metallic central tube filled optical cable; low-voltage power cable insulation core 6 is covered with plastic insulating layer; tape layer 3 and filling layer 4 are flame retardant Material layer; the armor layer 2 is a doubl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com