Integrated transformer

A technology of transformers and voltage transformers, which is applied in the direction of inductors, transformers, high-voltage air circuit breakers, etc., can solve the problems of cumbersome wiring, large volume, and expensive installation costs, and achieve the effect of beautiful appearance and easy installation

Inactive Publication Date: 2012-07-25

JIANGSU TIANCHI ELECTRIC

View PDF0 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The voltage transformer and current transformer are used in conjunction with the vacuum circuit breaker as an external type, which is large in size, cumbersome in wiring, and consumes installation costs

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

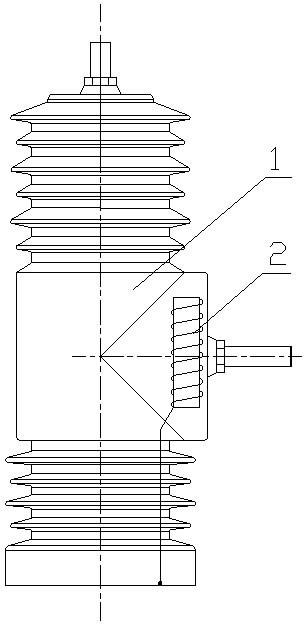

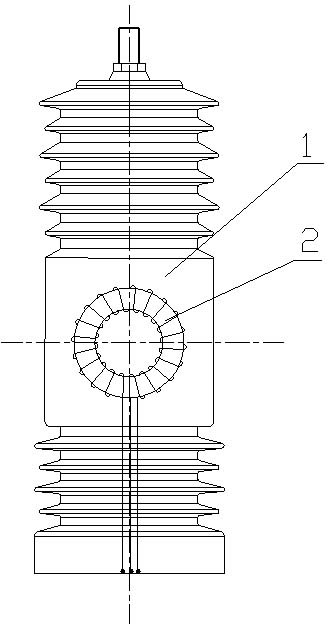

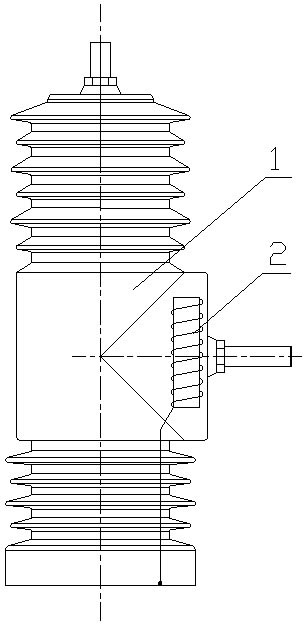

[0008] Such as figure 1 , 2 As shown, the epoxy resin insulating cylinder 1 is formed by pouring epoxy resin, and the voltage transformer and the current transformer 2 are arranged in the epoxy resin insulating cylinder 1, and the voltage transformer and the current transformer are arranged at the lower bottom of the epoxy resin insulating cylinder 1. The signal output terminal of transformer 2.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

An integrated transformer relates to the technical field of production of outdoor high-voltage permanent-magnet vacuum circuit breakers. A voltage transformer and a current transformer are arranged in an epoxy resin insulating cylinder, and signal outlet terminals of the voltage transformer and the current transformer are arranged at the bottom of the epoxy resin insulating cylinder. Compared with the conventional integrated transformer, the integrated transformer has the advantages that actual current and voltage values on the primary line can be accurately converted into low secondary current and low secondary voltage which cannot interfere with each other to bring convenience to measurement during running due to the fact that the current transformer and the voltage transformer are hermetically cast in a casting body provided with a vacuum arc-extinguishing chamber. Accordingly, error caused by complicated wiring of mounted integrated transformer during mounting on sites can be avoided on the premise of keeping function constant, the mounting process is simplified and the integrated transformer is more attractive in appearance.

Description

technical field [0001] The invention relates to the technical field of outdoor high-voltage permanent magnet vacuum circuit breaker production. Background technique [0002] The current transformers used in medium-voltage vacuum circuit breakers include voltage transformers and current transformers, which are independent of each other. The voltage transformer and current transformer are used in conjunction with the vacuum circuit breaker as an external type, which is large in size, cumbersome in wiring, and consumes installation costs. Contents of the invention [0003] The purpose of the invention is to propose a comprehensive transformer which is convenient to install. [0004] In the present invention, a voltage transformer and a current transformer are arranged in the epoxy resin insulating cylinder, and the signal connection terminals of the voltage transformer and the current transformer are arranged at the lower bottom of the epoxy resin insulating cylinder. [00...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): H01F38/34H01H33/66

Inventor 邹迅赵爱峰

Owner JIANGSU TIANCHI ELECTRIC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com