Automatic emergency syringe

A syringe and automatic technology, applied in the field of syringes, can solve the problems of complex operation, long waste of time, difficult disinfection, etc., and achieve the effect of ensuring hygiene and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings. The specific embodiments in the specification are preferred technical solutions of the present invention, and do not constitute limitations to the present invention.

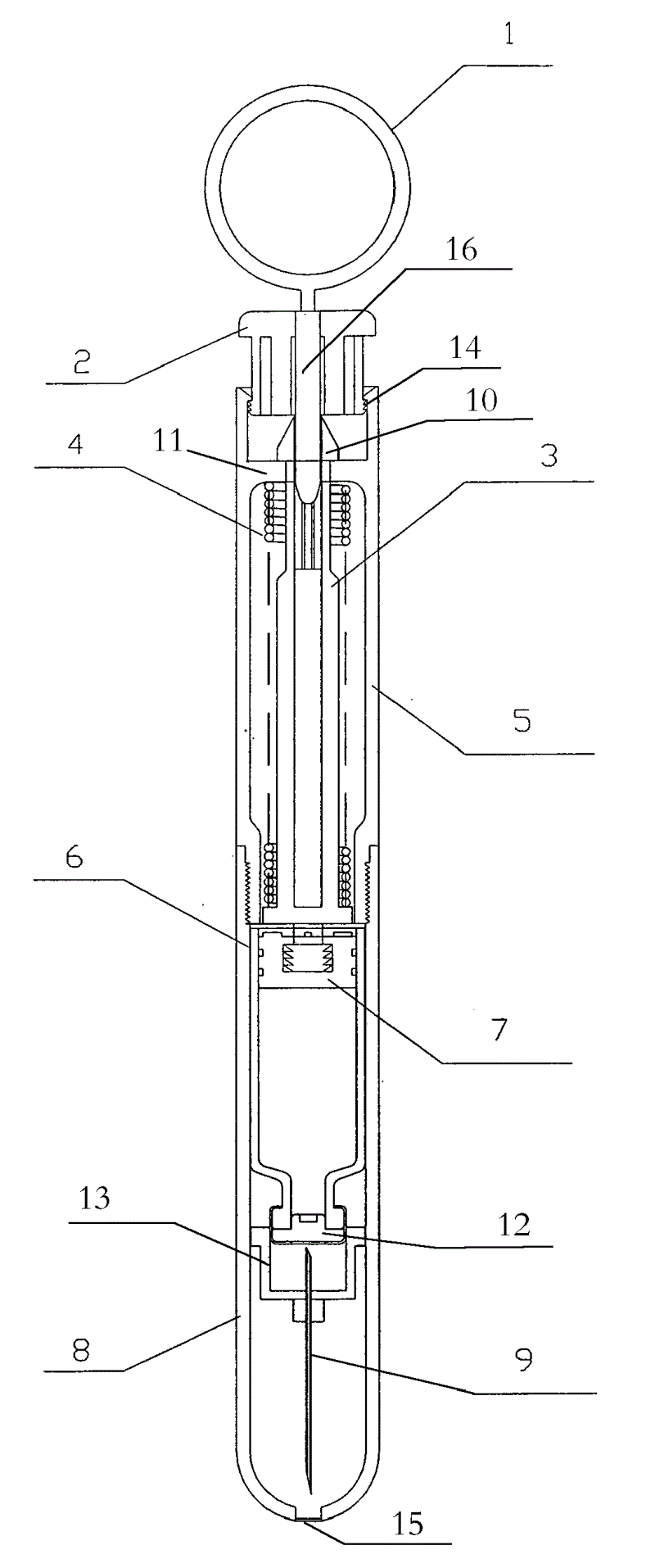

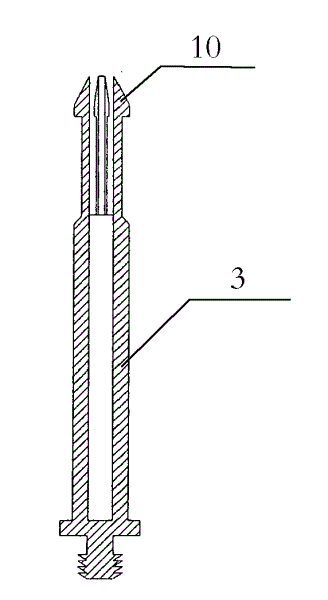

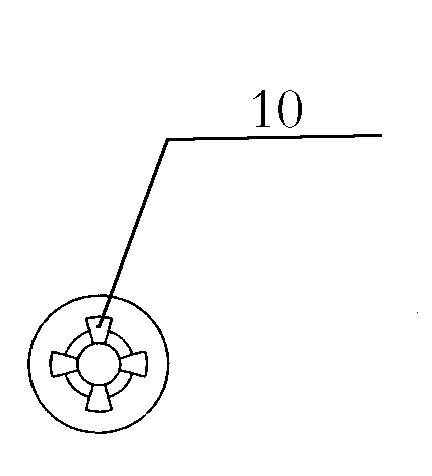

[0027] figure 1 It is a schematic diagram of the internal structure of the automatic emergency injector according to the present invention. Wherein, the automatic emergency syringe generally includes a firing part and a drug-loading part, the firing part has a safety pull ring 1, a firing device 2, an ejection rod 3, a spring 4, and an upper cylinder body 5, and the drug-loading part has a liquid cartridge 6. Piston 7, lower cylinder 8 and injection needle 9. The safety pull ring 1 is inserted in the firing device 2, and is used to prevent the false shooting of the firing device 2 from firing. An inner ring 11 is arranged inside the upper cylinder body 5 , and the inner ring 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com