Tower crane climbing frame and tower crane comprising same

A climbing frame and tower crane technology, applied to cranes and other directions, can solve the problems of high transportation cost, large space, space waste, etc., and achieve the effects of reducing transportation space occupation, improving assembly efficiency, and reducing transportation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Hereinafter, the present invention will be described in detail with reference to the drawings and examples. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

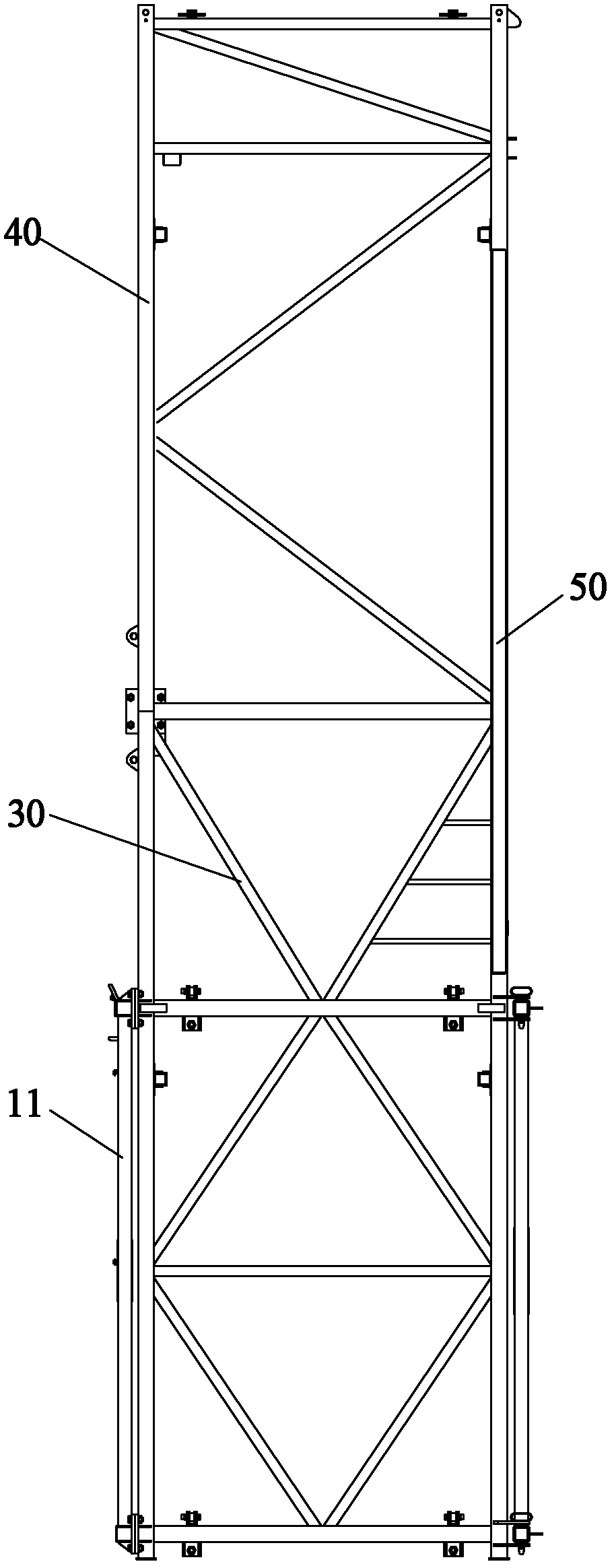

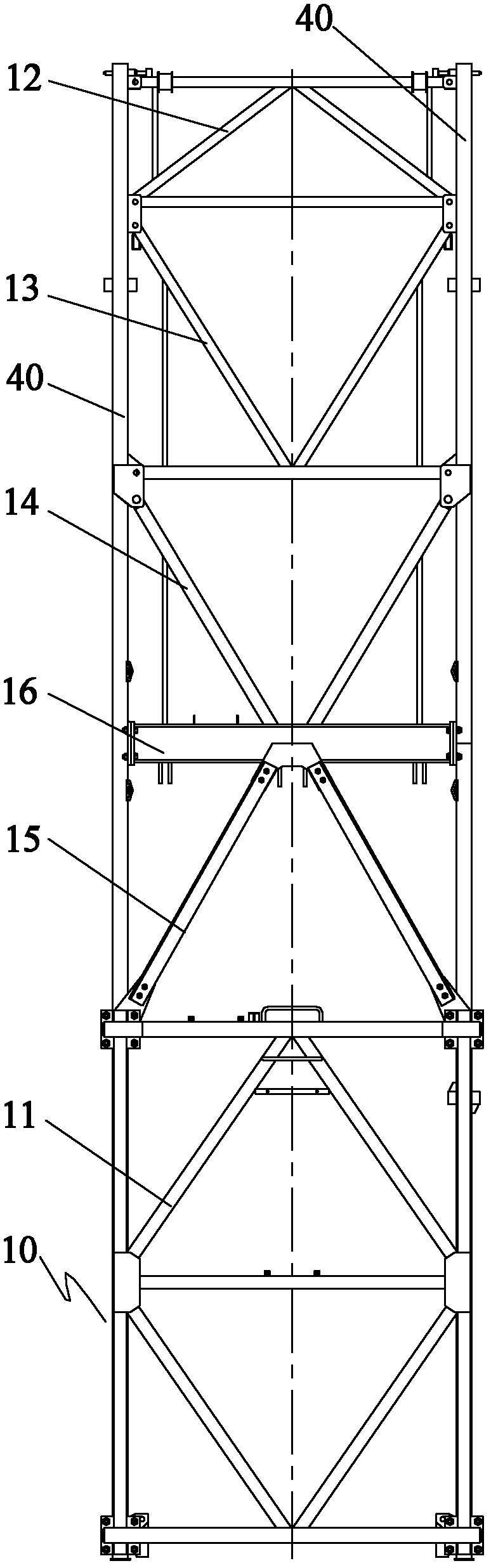

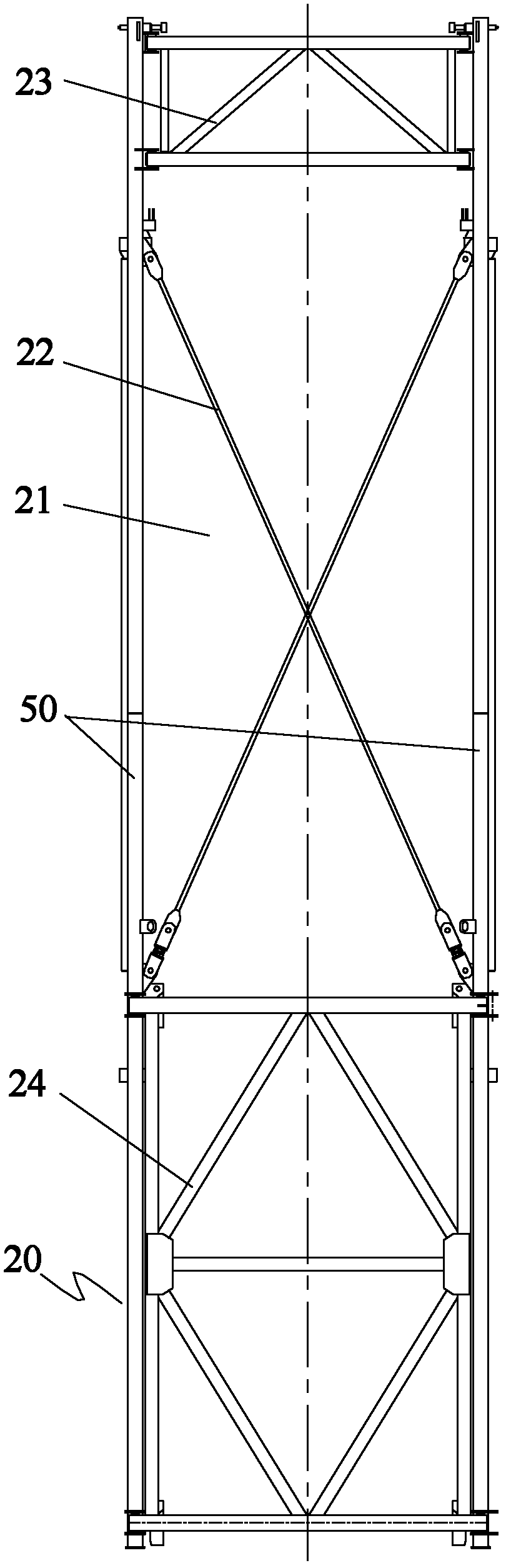

[0025] like Figure 1 to Figure 3 As shown, according to the embodiment of the present invention, the tower crane climbing frame includes a climbing surface 10 and an introduction surface 20 arranged oppositely, and two connecting surfaces 30 connected between the climbing surface 10 and the introduction surface 20, the climbing surface 10, the introduction surface The surface 20 and the two connecting surfaces 30 are detachably connected through four main chords. Wherein the climbing surface 10 and the introduction surface 20 each comprise at least one set of sheet structures, which are integral structures and detachably connected to the main chord. The two connection surfaces 30 can be welded tog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com