Cement-free anti-water dispersion and anti-water corrosion synchronous grouting material and its preparation method

A water-resistant dispersion and synchronous grouting technology, applied in the field of inorganic non-metallic building materials, can solve the problems of stratified segregation of slurry, affecting construction quality, and floating of segments, and achieves rapid strength growth in the later stage, good water resistance and dispersion, The effect of low fluidity loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

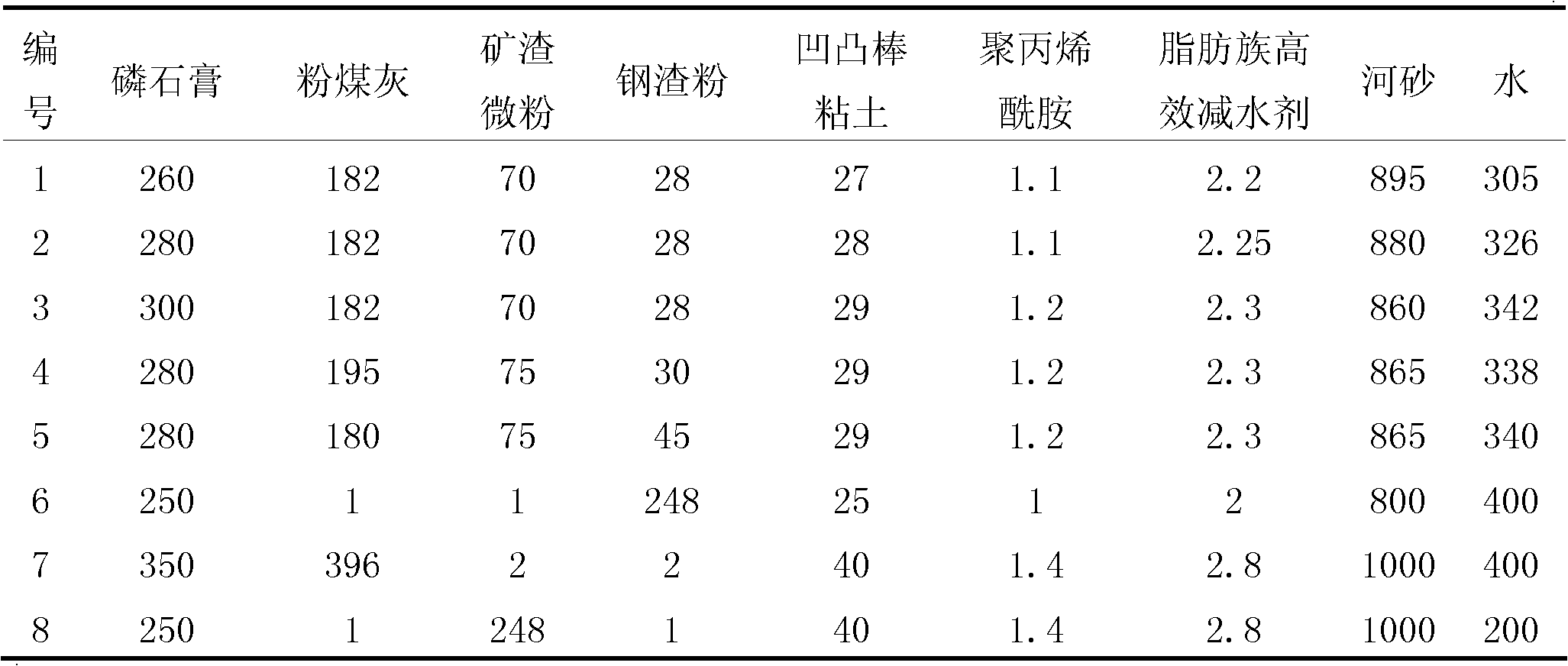

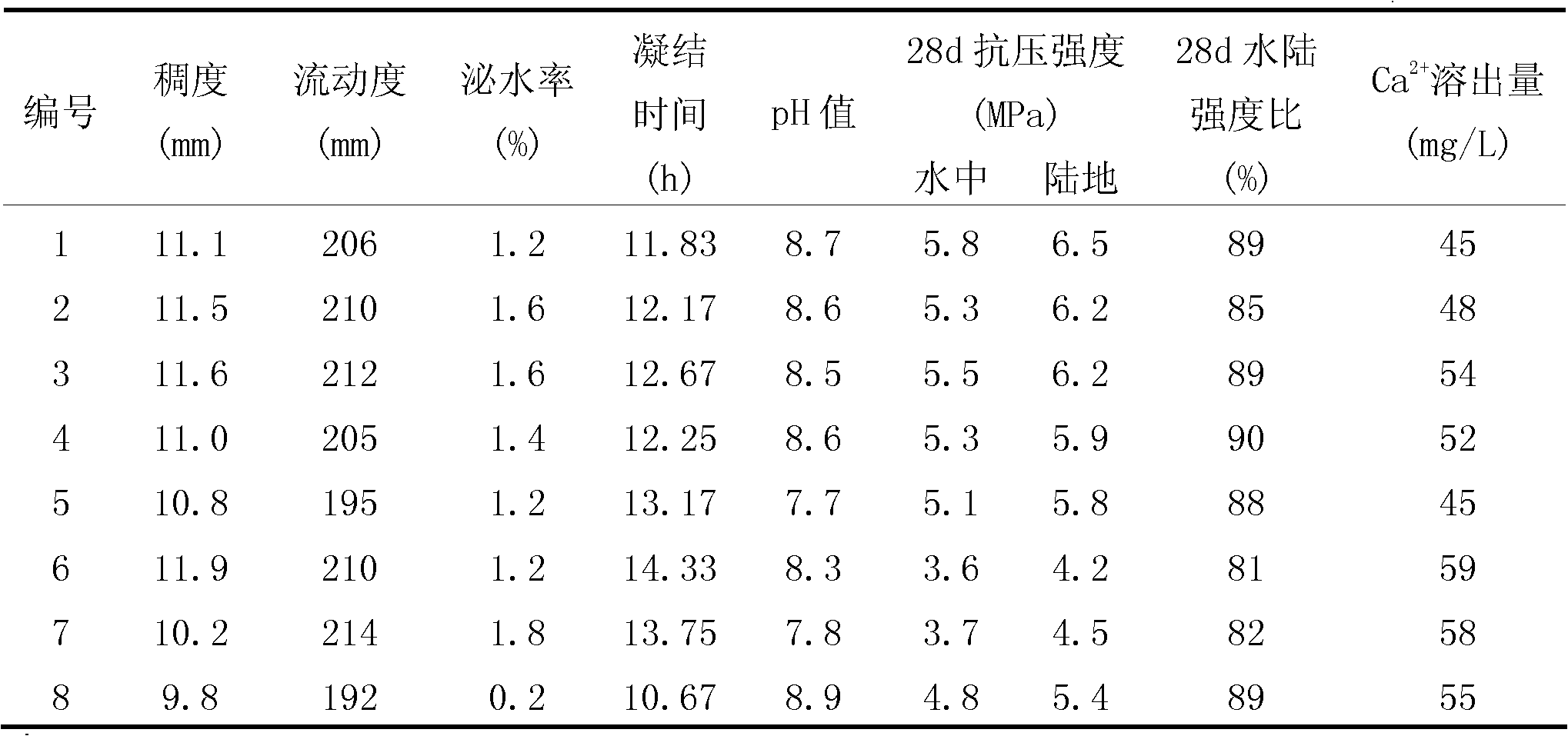

Embodiment 1

[0064] A method for preparing a cementless, water-dispersed, and water-corroded synchronous grouting material, comprising the steps of:

[0065] 1) Selection of raw materials: weight ratio of each component (kg / m 3 ) is: phosphogypsum: 260, fly ash + slag powder + steel slag powder: 280, attapulgite clay: 27, polyacrylamide: 1.1, aliphatic superplasticizer: 2.2, river sand: 895, water: 305; Among them, fly ash, slag powder, and steel slag powder account for the total percentage of the three: fly ash: 65%, slag powder: 25%, and steel slag powder 10%.

[0066] The phosphogypsum is solid waste from a phosphate fertilizer plant, and its main component is undisturbed phosphogypsum dihydrate; the fly ash is a primary or secondary fly ash with a specific surface area greater than 3500 cm 2 / g; the slag micropowder is blast furnace slag, the specific surface area is greater than 4500cm 2 / g; said steel slag powder is raw steel slag powder available on the market, with effective CaO ...

Embodiment 2

[0070] A method for preparing a cementless, water-dispersed, and water-corroded synchronous grouting material, comprising the steps of:

[0071] 1) Selection of raw materials: weight ratio of each component (kg / m 3 ) is: phosphogypsum: 280, fly ash + slag powder + steel slag powder: 280, attapulgite clay: 28, polyacrylamide: 1.1, aliphatic superplasticizer: 2.25, river sand: 880, water: 326; Among them, fly ash, slag powder, and steel slag powder account for the total percentage of the three: fly ash: 65%, slag powder: 25%, and steel slag powder 10%.

[0072] The phosphogypsum is solid waste from a phosphate fertilizer plant, and its main component is undisturbed phosphogypsum dihydrate; the fly ash is a primary or secondary fly ash with a specific surface area greater than 3500 cm 2 / g; the slag micropowder is blast furnace slag, the specific surface area is greater than 4500cm 2 / g; The steel slag powder described is the raw steel slag powder available on the market, with ...

Embodiment 3

[0076] A method for preparing a cementless, water-dispersed, and water-corroded synchronous grouting material, comprising the steps of:

[0077] 1) Selection of raw materials: weight ratio of each component (kg / m 3 ) is: phosphogypsum: 300, fly ash + slag powder + steel slag powder: 280, attapulgite clay: 29, polyacrylamide: 1.2, aliphatic superplasticizer: 2.3, river sand: 860, water: 342; Among them, fly ash, slag powder, and steel slag powder account for the total percentage of the sum of the three: fly ash: 65%, slag powder: 25%, and steel slag powder 10%.

[0078] The phosphogypsum is solid waste from a phosphate fertilizer plant, and its main component is undisturbed phosphogypsum dihydrate; the fly ash is a primary or secondary fly ash with a specific surface area greater than 3500 cm 2 / g; the slag micropowder is blast furnace slag, the specific surface area is greater than 4500cm 2 / g; the steel slag powder is raw steel slag powder available on the market, with an e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com