Light shading adhesive, laminated plate, preparation method of light shading adhesive, and application of light shading adhesive

A technology of sunscreening agent and adhesive, which is applied in the fields of laminates, sunscreening adhesives and their preparations, can solve the problems of laminated boards having no light-shielding effect, poor light-shielding effect, poor heat resistance and weather resistance, and achieve excellent Shading function, increase light intensity, energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Raw material components (parts by weight) of light-shielding adhesive:

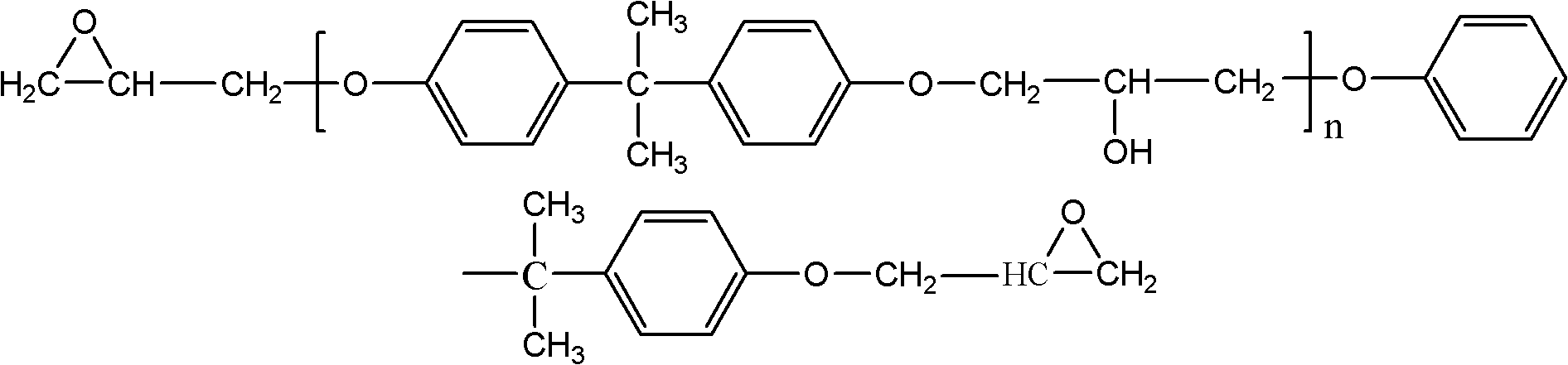

[0049] Bisphenol A epoxy resin: 125 parts

[0050] Dicyandiamide: 2.9 parts

[0051] 2-Methylimidazole: 0.065 parts

[0052] Dimethylformamide: 20 parts

[0053] Propylene glycol methyl ether: 12 parts

[0054] Nigrosine: 0.8 parts

[0055] Aluminum hydroxide: 20 parts

[0056] The preparation method of the light-shielding adhesive: first dissolve dicyandiamide and 2-methylimidazole in dimethylformamide and propylene glycol methyl ether, and stir for 4 hours at a speed of 1000rpm; after it is completely dissolved, add bisphenol A epoxy resin, fully stirred at 1200rpm for 3 hours; after mixing evenly, add nigrosine and aluminum hydroxide, disperse with high shear at 3500rpm for 45 minutes, then stir at 1200rpm for 5 hours, after complete aging That's it.

Embodiment 2

[0058] Raw material components (parts by weight) of light-shielding adhesive:

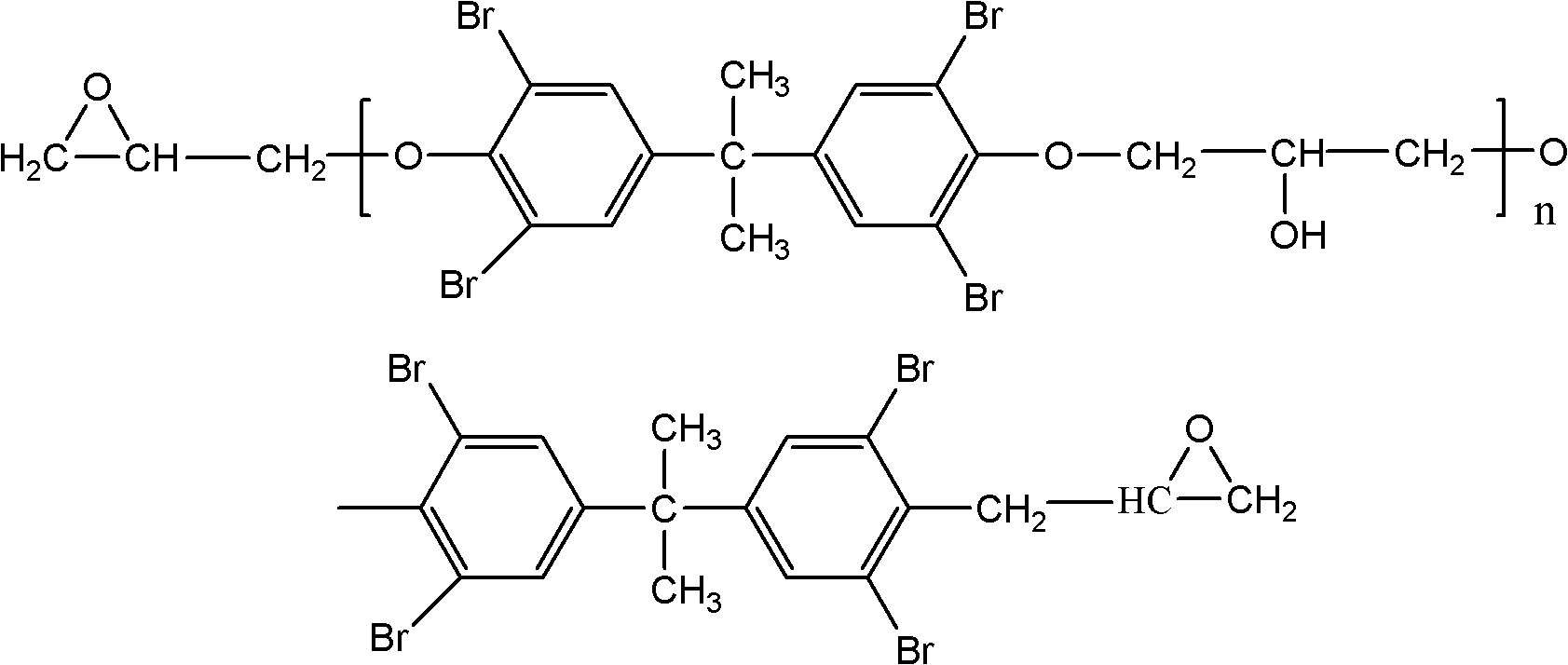

[0059] Brominated epoxy resin: 130 parts

[0060] Dicyandiamide: 3.1 parts

[0061] 2-Methylimidazole: 0.080 parts

[0062] Dimethylformamide: 25 parts

[0063] Propylene glycol methyl ether: 17 parts

[0064] Nano titanium dioxide: 10 parts

[0065] Nano zinc oxide: 12 parts

[0066] Aluminum hydroxide: 15 parts

[0067] The preparation method of the light-shielding adhesive: first dissolve dicyandiamide and 2-methylimidazole in dimethylformamide and propylene glycol methyl ether, and stir at a speed of 1000rpm for 4 hours; after it is completely dissolved, add bromide Epoxy resin is fully stirred for 3 hours at 1200rpm with a rotating speed; after mixing evenly, add nano-titanium dioxide, nano-zinc oxide and aluminum hydroxide, and disperse at a high shear rate of 4500rpm for 60 minutes with a rotating speed, and then stir at 1200rpm for 6 hours. It can be fully ripened.

Embodiment 3

[0069] Raw material components (parts by weight) of light-shielding adhesive:

[0070] Resin: Phosphorus-containing epoxy resin: 125 parts

[0071] Phenolic resin: 15 parts

[0072] Curing agent: benzoxazine resin: 10 parts

[0073] Phenolic resin: 5 parts

[0074] 2-Ethyl-4-methylimidazole: 0.050 parts

[0075] Butanone: 14 parts

[0076] Propylene glycol methyl ether: 10 parts

[0077] Nigrosine: 1.1 parts

[0078] Aluminum hydroxide: 15 parts

[0079] The preparation method of the light-shielding adhesive: first dissolve 2-ethyl-4-methylimidazole in butanone and propylene glycol methyl ether, and stir at a speed of 1000rpm for 3 hours; after it is completely dissolved, add phosphorus-containing epoxy Resin, phenolic resin, benzoxazine resin, fully stirred at 1200rpm for 4 hours; after mixing evenly, add nigrosine and aluminum hydroxide, disperse with high shear at 3500rpm for 60 minutes, and then stir at 1200rpm 5 hours, after fully ripening.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com