Water-based rust-conversion type thermal insulation coating with high corrosion resistance

A technology of high corrosion resistance and heat insulation coating, applied in anti-corrosion coatings, reflective/signal coatings, etc., to achieve the effect of strong coating adhesion, good fluidity and high reflectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

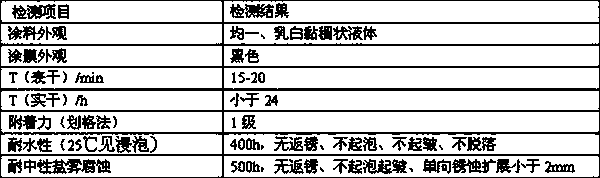

Examples

Embodiment 1

[0027] A high-corrosion-resistant water-based rust-transforming heat-insulating coating, the raw materials of which include the following components by weight: 5 parts of vinyl chloride emulsion, 25 parts of G-OAL chelating embroidery agent, 6 parts of hollow glass microspheres, nano 12 parts of TiO2, 10 parts of sericite, 8 parts of titanium dioxide, 10 parts of talcum powder, 2 parts of aluminum tripolyphosphate, 0.9 parts of dispersant, 0.1 part of wetting agent, 0.3 parts of defoamer, 3.0 parts of film-forming aid, 1.5 parts of thickener, 1 part of pH regulator, 20 parts of deionized water.

[0028] The rust reducing agent G-OAL is mainly prepared by mixing 3,4,5-trihydroxy-2-oximinobenzoic acid, ethanol and isopropanol in a mass ratio of 2:1:1. Among them, 3,4,5-trihydroxy-2-oximinobenzoic acid is prepared by modifying 3,4,5-trihydroxybenzoic acid, and the carboxyl, hydroxyl, and oxime groups contained in its molecule can chelate with rust Coordination effect, so as to s...

Embodiment 2

[0040]A high-corrosion-resistant water-based rust-transforming heat-insulating coating, the raw materials of which include the following components by weight: 30 parts of vinyl chloride emulsion, 50 parts of G-OAL chelating type embroidery agent, 12 parts of hollow glass microspheres, nano 25 parts of TiO2, 20 parts of sericite, 12 parts of titanium dioxide, 20 parts of talcum powder, 10 parts of aluminum tripolyphosphate, 1.5 parts of dispersant, 0.3 parts of wetting agent, 0.8 parts of defoamer, 6.0 parts of film-forming aid, 3.5 parts of thickening agent, 3 parts of pH regulator, 50 parts of deionized water.

[0041] The rust reducing agent G-OAL is mainly prepared by mixing 3,4,5-trihydroxy-2-oximinobenzoic acid, ethanol and isopropanol in a mass ratio of 2:1:1. Among them, 3,4,5-trihydroxy-2-oximinobenzoic acid is prepared by modifying 3,4,5-trihydroxybenzoic acid, and the carboxyl, hydroxyl, and oxime groups contained in its molecule can chelate with rust Coordination e...

Embodiment 3

[0053] A high-corrosion-resistant water-based rust-transforming heat-insulating coating, the raw materials of which include the following components by weight: 25 parts of vinyl chloride emulsion, 35 parts of G-OAL chelating embroidery agent, 9 parts of hollow glass microspheres, nano 22 parts of TiO2, 15 parts of sericite, 9 parts of titanium dioxide, 15 parts of talcum powder, 8 parts of aluminum tripolyphosphate, 1.2 parts of dispersant, 0.2 parts of wetting agent, 0.5 parts of defoamer, 5.0 parts of film-forming aid, 2.5 parts of thickener, 2 parts of pH regulator, 35 parts of deionized water.

[0054] The rust reducing agent G-OAL is mainly prepared by mixing 3,4,5-trihydroxy-2-oximinobenzoic acid, ethanol and isopropanol in a mass ratio of 2:1:1. Among them, 3,4,5-trihydroxy-2-oximinobenzoic acid is prepared by modifying 3,4,5-trihydroxybenzoic acid, and the carboxyl, hydroxyl, and oxime groups contained in its molecule can chelate with rust Coordination effect, so as t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com