Threading silk yarn lifting mechanism used on threading silk yarn spring test equipment

A technology of testing equipment and lifting mechanism, which is applied to auxiliary equipment for weaving, textile, textile and papermaking, etc., can solve the problems of no special equipment for wire springs and long testing time, and achieve the effect of shortening test results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

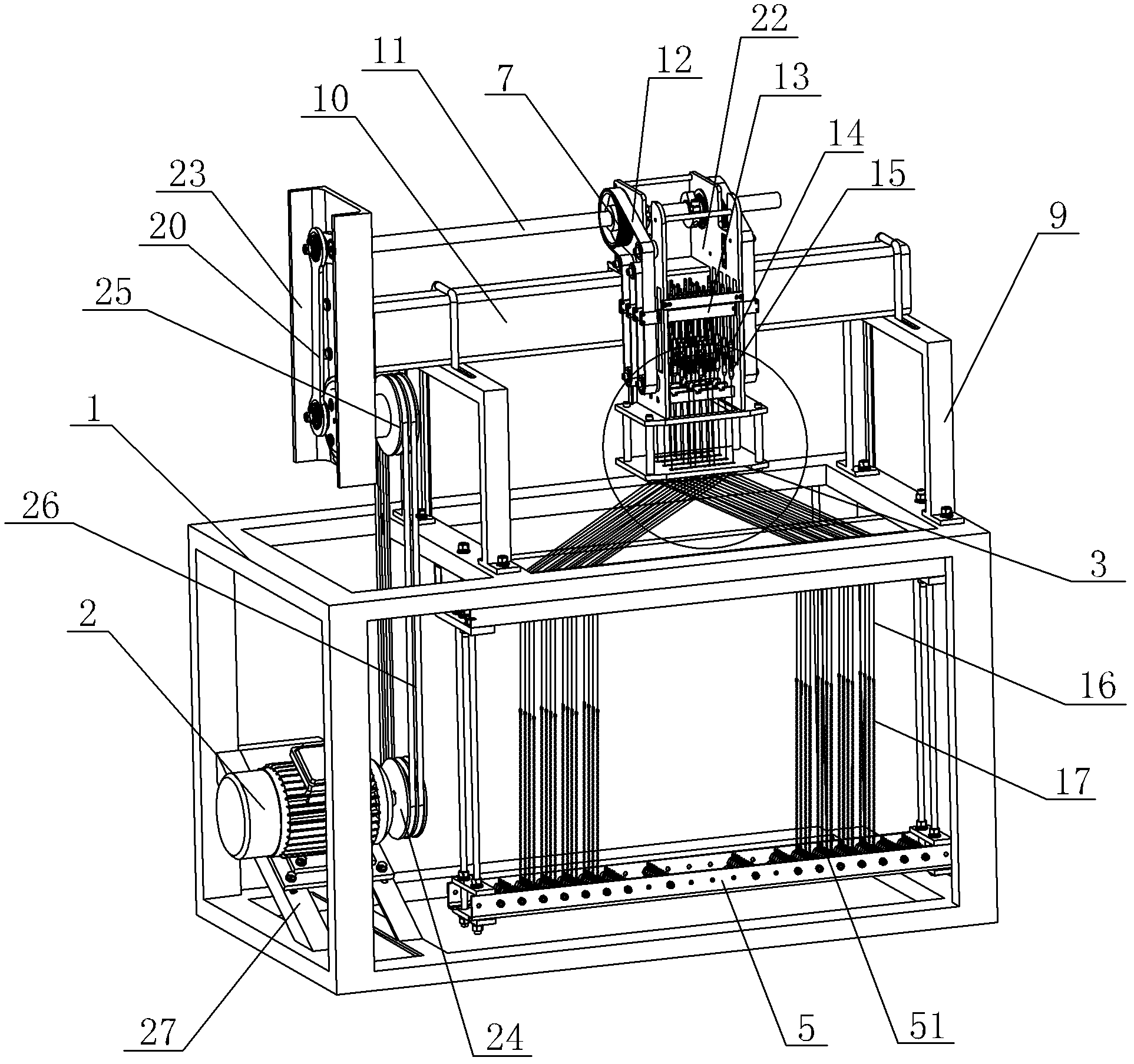

[0017] Such as figure 2 , the wire spring testing equipment of the wire wire lifting mechanism of the present invention is housed, comprising a bed body 1, a motor 2, a return heald frame 5, the output end of the motor 2 is connected to a crank rocker mechanism, and the crank rocker mechanism is connected to a transmission shaft 11, and the transmission The shaft 11 is connected with the thread-through lifting mechanism, the transmission belt 12 of the thread-through lifting mechanism is fixed with a hook clip 13, the hook clip 13 is fixed with a joint hook 14, the joint hook 14 is connected with a quick connector 15, and the quick connector 15 is connected with a thread 16 , the threading thread 16 passes through the threading hole 31 on the threading plate 3 and the eyelet 41 on the frame 4 in turn, the threading thread 16 is connected to the spring 17 below the frame 4 through the heald rod, and the spring 17 is fixed on the heddle Box 5 on.

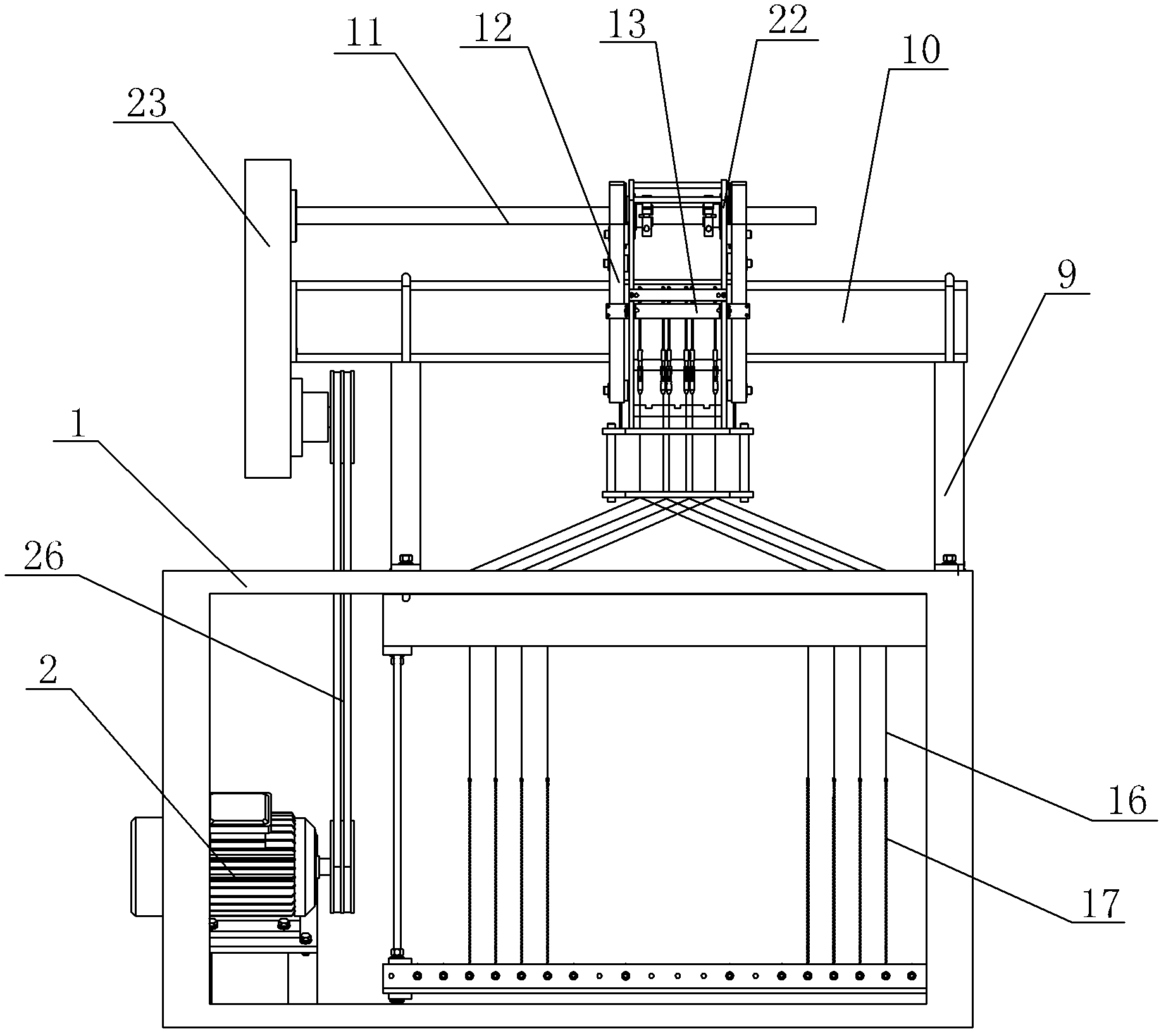

[0018] Such as image 3 , t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com