High-speed testing device for harnessstrings spring

A technology of testing equipment and silk thread, which is applied in the direction of applying repeated force/pulsation force to test the strength of materials, etc. It can solve the problems of long test time, poor effect, and complexity of transmission mechanism, etc., and achieve shortened test results and simple and direct transmission mechanism Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

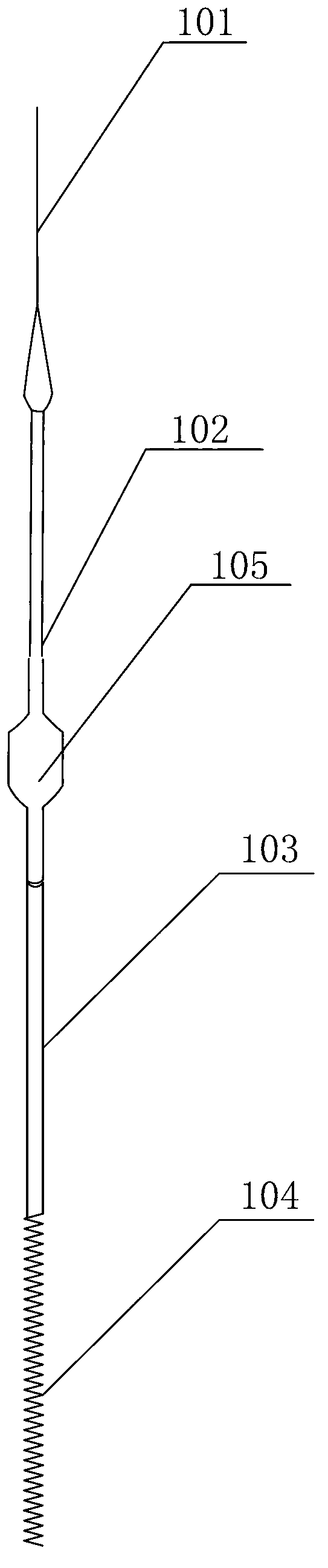

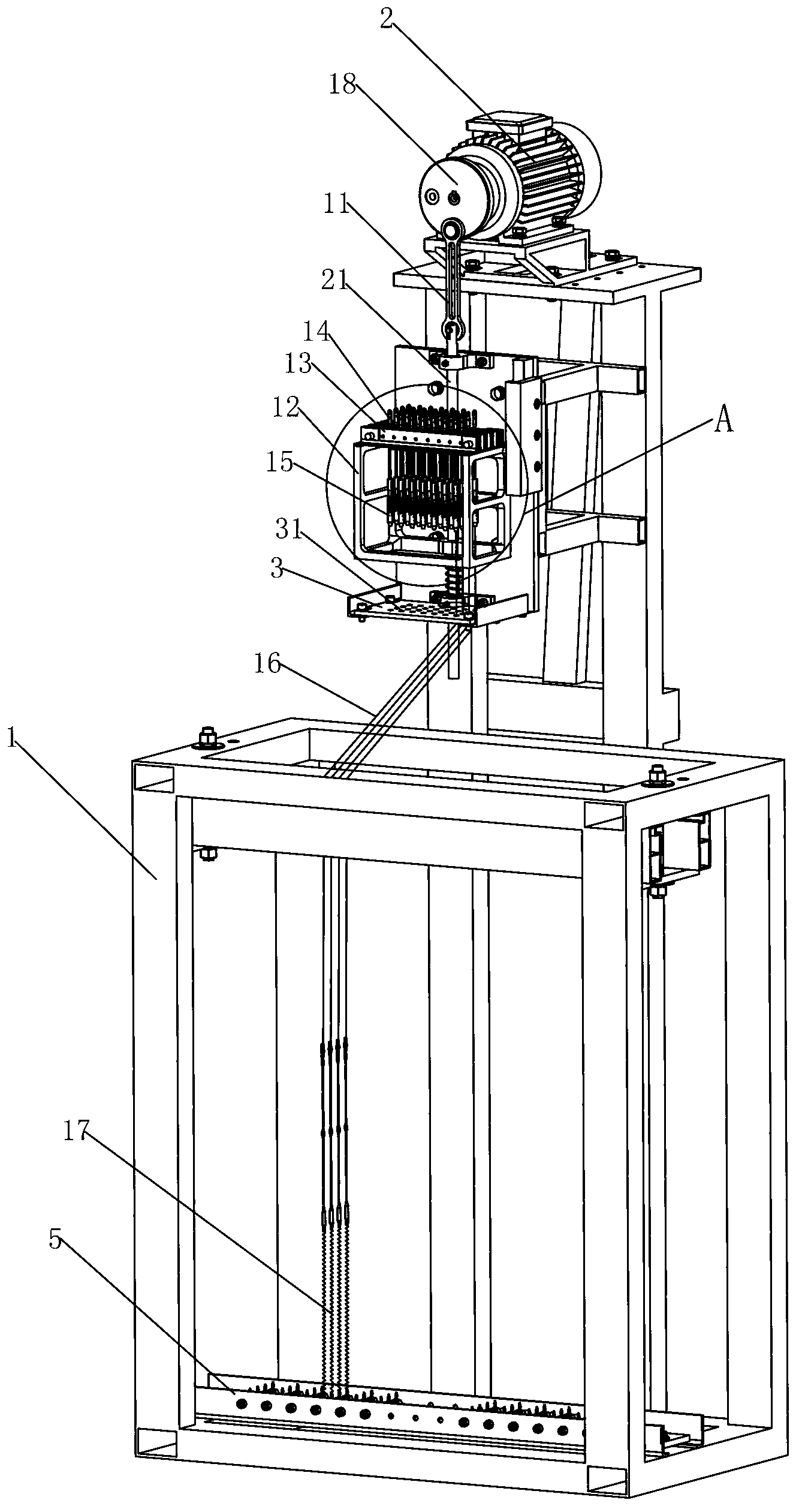

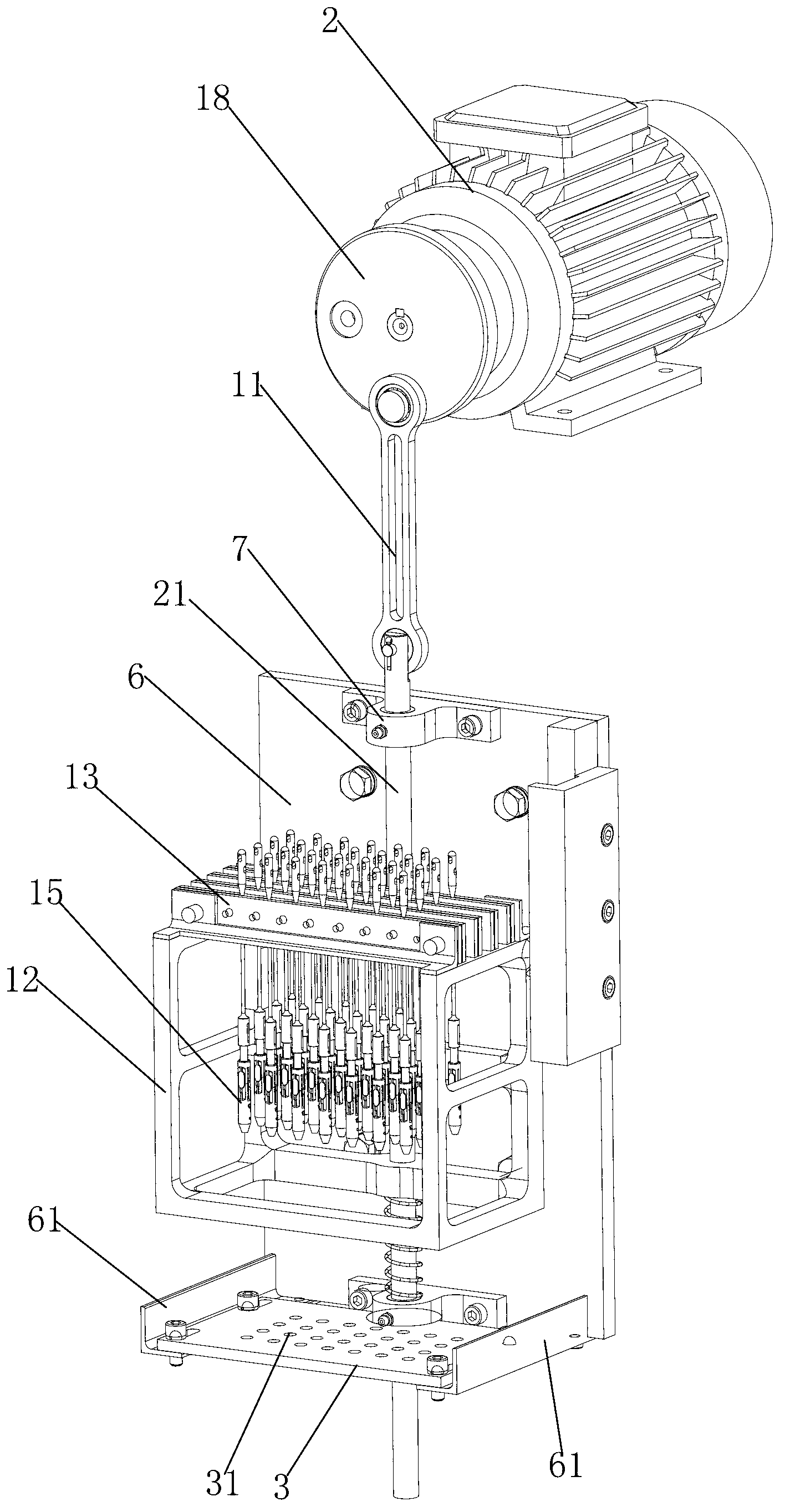

[0016] like Figure 2-5 , a kind of wire spring high-speed testing equipment, comprising a frame 1, a motor 2 is arranged on the top of the frame 1, the output end of the motor 2 is connected to an eccentric wheel 18, the eccentric wheel 18 is connected to a transmission shaft 11, the transmission shaft 11 is connected to a sliding shaft 21, and the The shaft 21 is radially fixed on the frame 1, the sliding shaft 21 is fixed with a wire thread fixing frame 12, the wire thread fixing frame 12 is provided with a hook clip 13, the hook clip 13 is fixed with a joint hook 14, and the joint hook 14 is connected There is a quick connector 15 for connecting the wire, the quick connector 15 is provided with a threading plate 3 and an eye plate frame through which the thread 16 passes through in turn, the threading plate 3 is provided with a threading hole 31, and the eye plate frame is provided with an eyelet. The frame 1 bottom is provided with the return heald frame 5 of fixed spring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com