Motor-driven mechanism stroke start/end adjusting and positioning structure of sewing machine

A motor-driven, positioning structure technology, applied to sewing machine components, sewing machine control devices, sewing equipment, etc., can solve problems such as insufficient stability, inaccurate movements, displacement or looseness, etc., to increase operating efficiency and improve stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

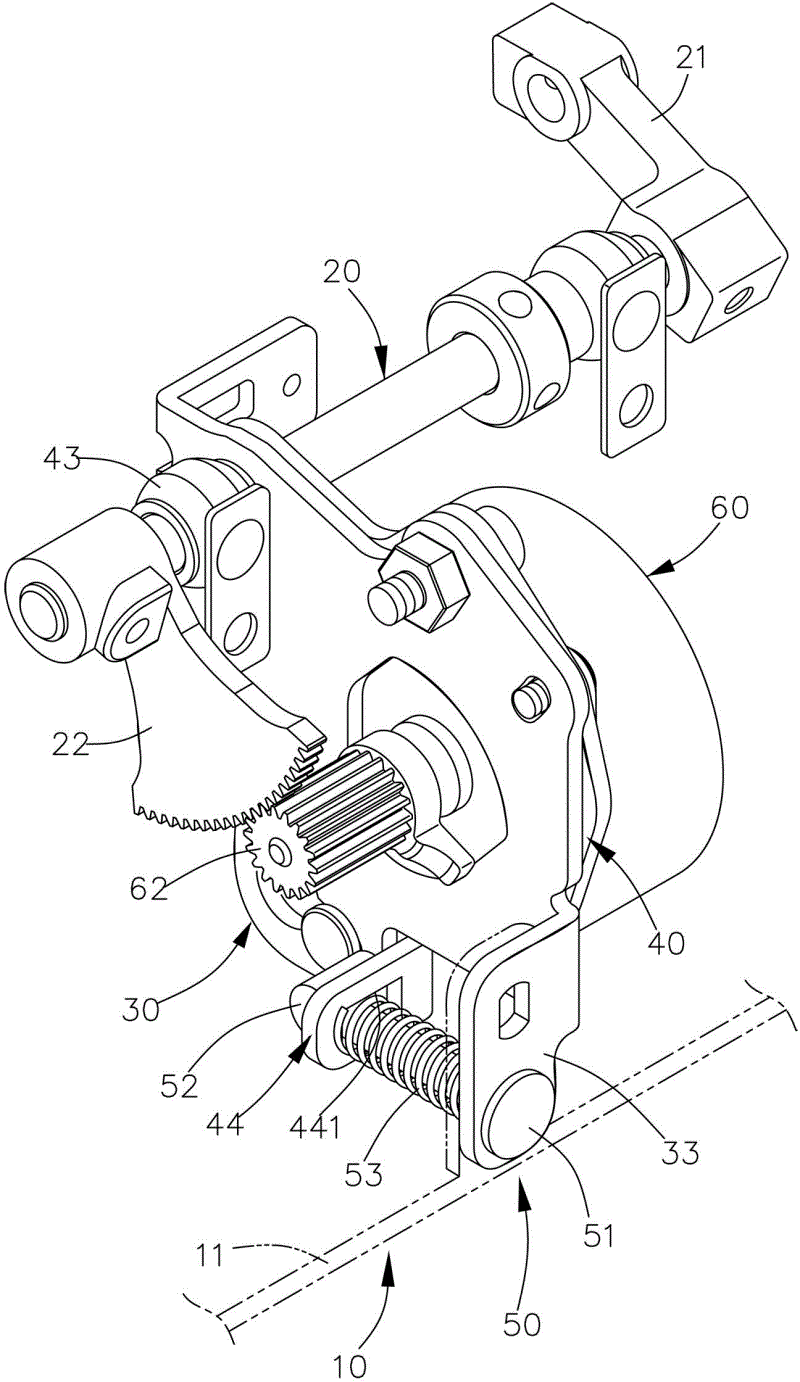

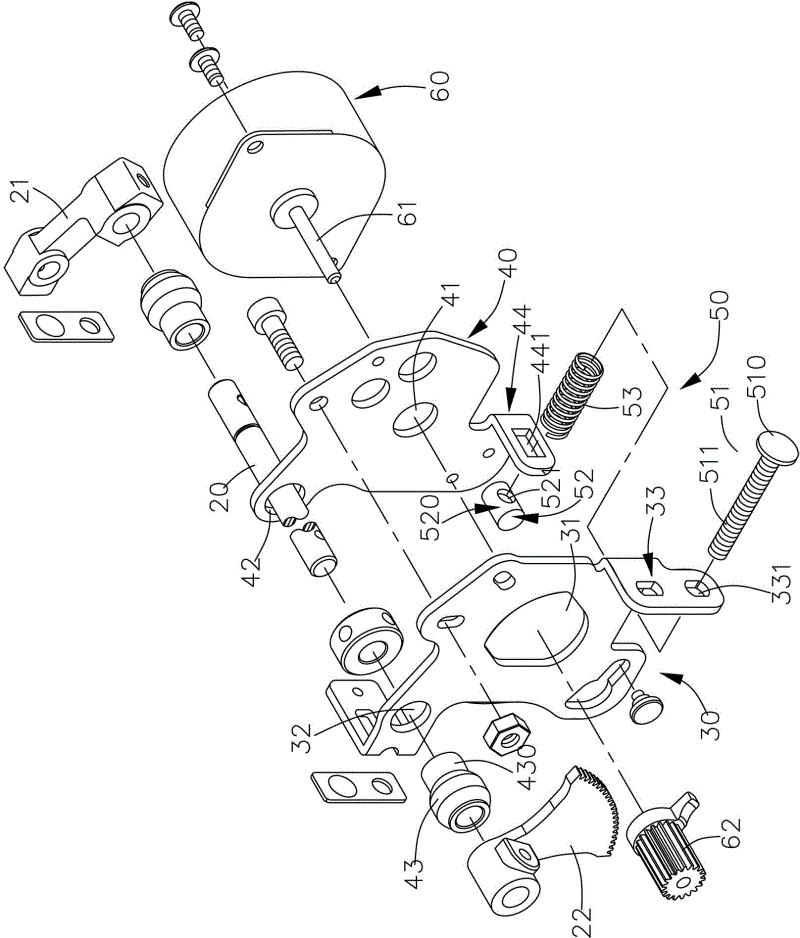

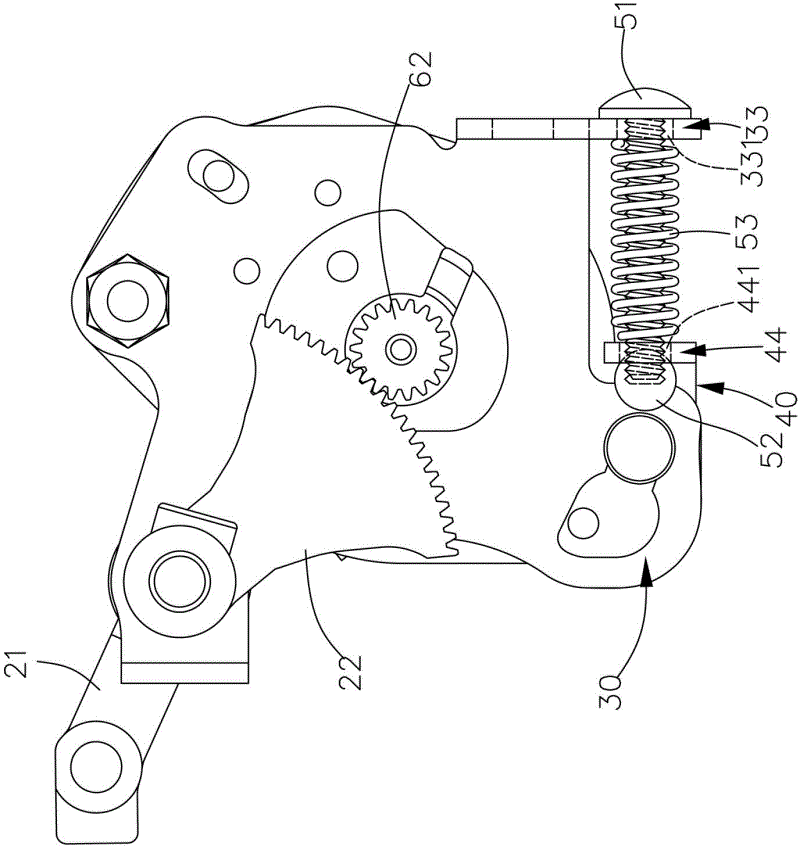

[0046] First, please refer to Figure 1 to Figure 3 As shown, the motor-driven mechanism of a sewing machine provided by the embodiment of the present invention has a stroke adjustment and positioning structure. The machine base 11 of the sewing machine 10 is provided with a control shaft 20, and one end of the control shaft 20 is provided with interlocking cloth feeding teeth. The swing arm 21, the other end is provided with a sector gear type control member 22, the motor adjustment and positioning structure includes a fixed seat 30, a positioning seat 40 and an adjustment device 50, wherein:

[0047] The fixing base 30 is a sheet-like structure, the fixing base 30 has a through hole 31 in the center, and a pivot hole 32 at the top, and the bottom end of the fixing base 30 is bent at 90 degrees to protrude. There is a fixing part 33, the fixing part 33 has a long piercing hole 331, the fixing base 30 is fixed on the machine base 11 of the sewing machine 10;

[0048] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com