Onboard oil injection quantity control self-learning method for common rail oil injector

A technology of common rail injector and fuel injection quantity, which is applied in fuel injection control, electrical control, engine control, etc. It can solve the problems of the limitation of learning effect and the inability to cover all the rail pressure of the engine, so as to achieve poor solution effect , improve OBD technology, realize the effect of on-vehicle diagnosis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings.

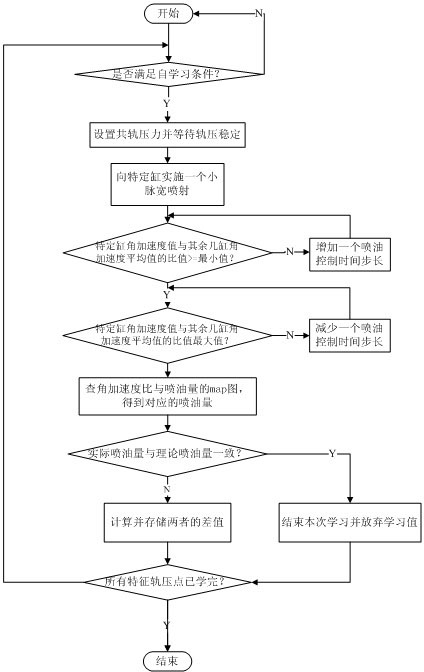

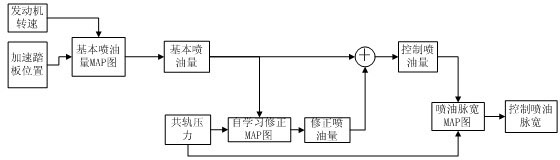

[0032] Step (1). If figure 2 As shown, during the operation of the whole vehicle, monitor the values of various characteristic parameters of the engine. If the monitored characteristic parameters: accelerator pedal position, control fuel injection volume, clutch status, gear position, water temperature, and fuel temperature are within the preset value range, Then the whole vehicle is in the working condition of the engine deceleration with the throttle being pulled back quickly, and the common rail pressure is quickly set to the characteristic rail pressure point to be self-learning. After the rail pressure is stable, the injector self-learning under the rail pressure is performed; if Characteristic parameters: Accelerator pedal position, fuel injection quantity control, clutch status, gear position, water temperature, fuel temperature are outside the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com