Diagnosis method for drift failure of rail pressure sensor in common rail system

A technology of rail pressure sensor and common rail system, which is applied in the direction of machine/engine, fuel injection control, engine control, etc., can solve the problems of increasing software overhead and cost, incomplete diagnosis of faults, and difficulty in starting, etc., to achieve on-board The effect of diagnosis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

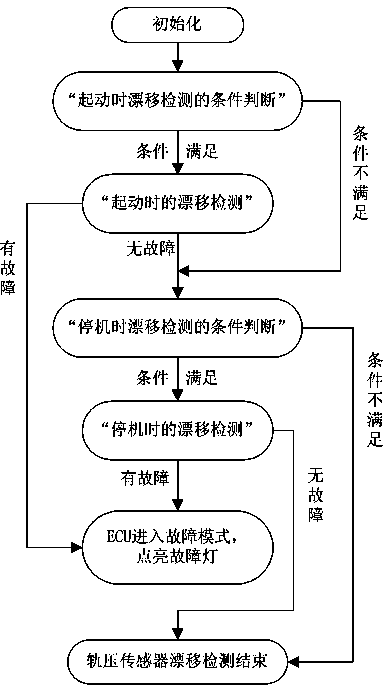

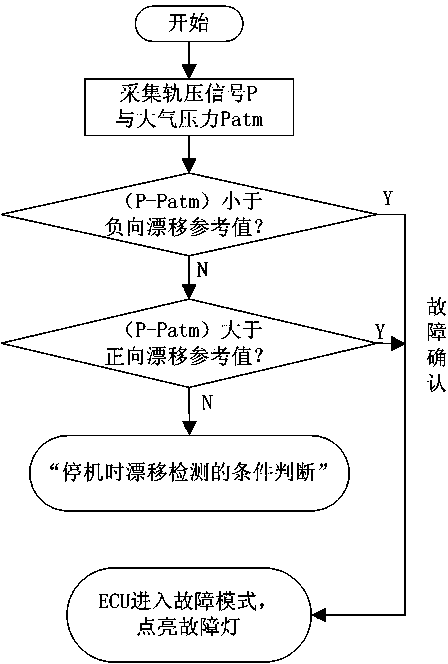

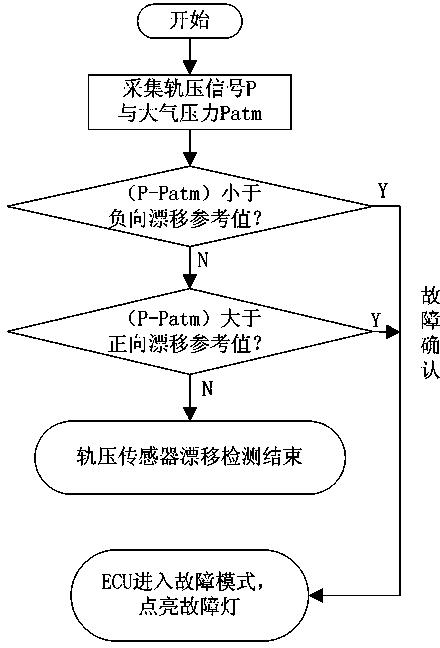

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0018] The diagnostic method for the drift fault of the rail pressure sensor in the common rail system of the present invention comprises the following steps:

[0019] Step 1. When the engine is stopped, after the common rail electronic control unit ECU (Electronic Control Unit) completes the initialization work, the ECU judges whether the conditions for the detection of the drift of the rail pressure sensor at the start are met; these conditions include: whether the ECU successfully stores the last Whether the cooling water temperature of the driving cycle, the difference between the cooling water temperature of the previous driving cycle and the current cooling water temperature are within a reasonable preset range, and whether the current cooling water temperature is higher than the critical temperature for the ECU to smoothly detect the drift detection of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com