Material conveying system for realizing high volume capacity in drying box

A transmission system and high-volume technology, which is applied in the field of mechanical manufacturing automation, can solve the problems of low productivity and low space utilization of drying ovens, and achieve the effect of improving production efficiency and volume ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

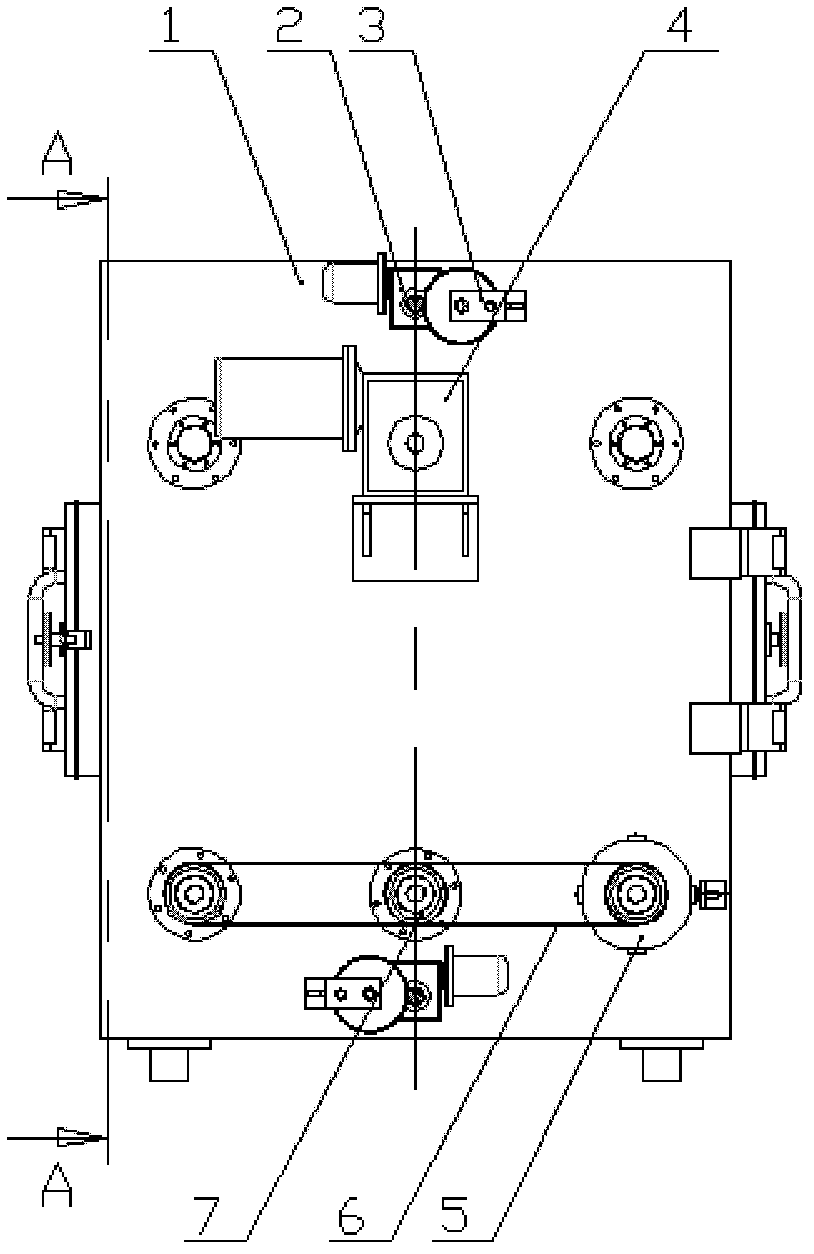

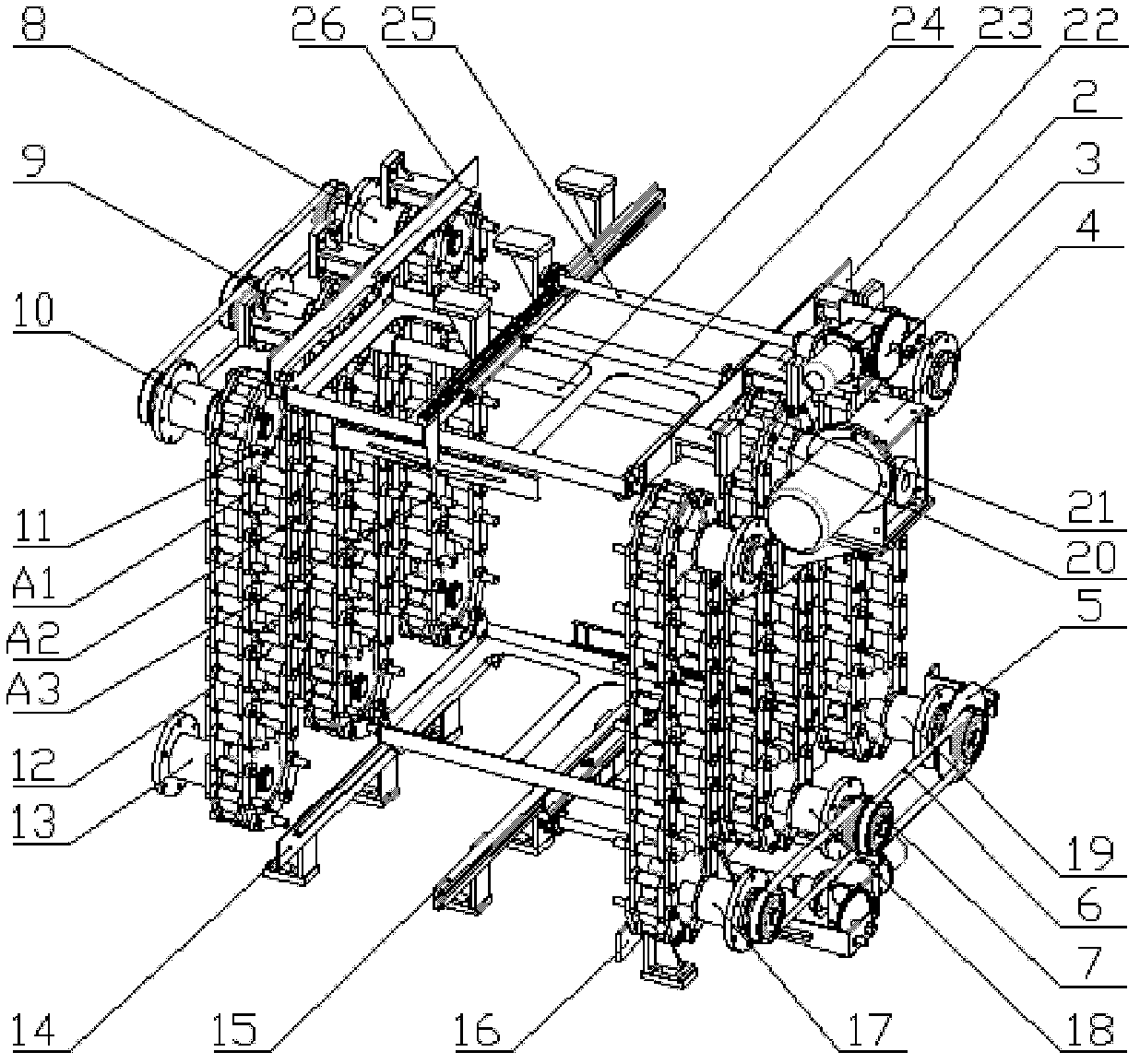

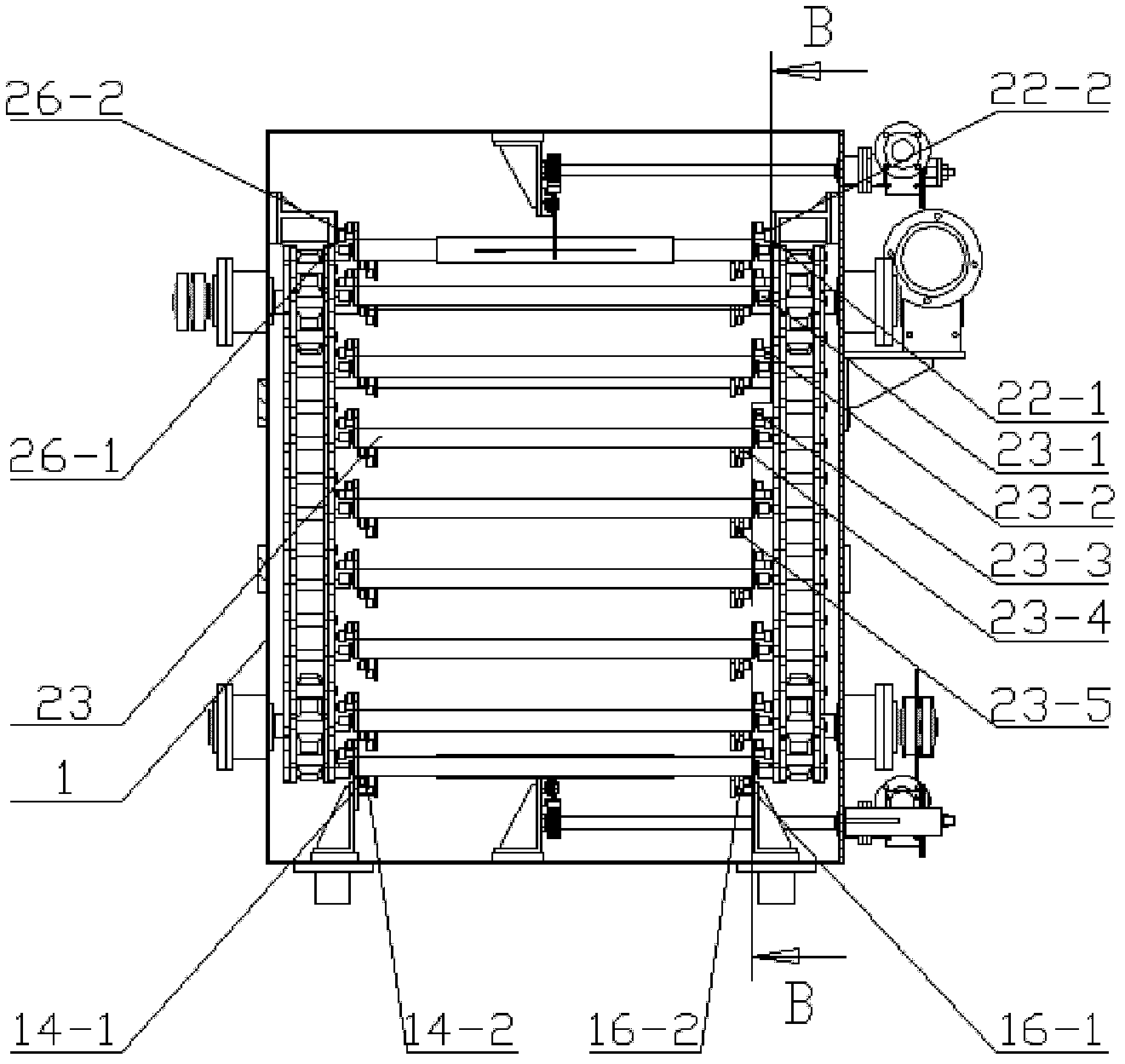

[0032] Example: see figure 1 , figure 2, a material conveying system that realizes a high volume ratio in a drying box, including a driving device and a material conveying chain device A; the material conveying chain device is composed of three sets of material conveying chain structures with the same structure, installed vertically, and parallel to each other Composed of A1, A2, and A3, the three groups of material conveying chain structures rotate synchronously; each group of material conveying chain structures is composed of left and right material conveying chains with the same structure on the left and right sides and facing each other. The right material conveyor chain is respectively provided with sprocket shafts parallel up and down, and sprocket wheels 21 are arranged on the inboard shaft ends of the sprocket shafts, and a pair of sprocket wheels 21 on each side are provided with chain 12; chain shafts are arranged on chain 12 11. A material conveying tray frame 23 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com