Heat exchanger

A heat exchanger and heat exchange core technology, applied in the direction of heat exchanger types, indirect heat exchangers, lighting and heating equipment, etc., can solve the problems of insufficient welding, limited use temperature and temperature resistance performance, and inconvenient cleaning. To achieve the effect of eliminating the risk of leakage, enhancing heat exchange efficiency and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

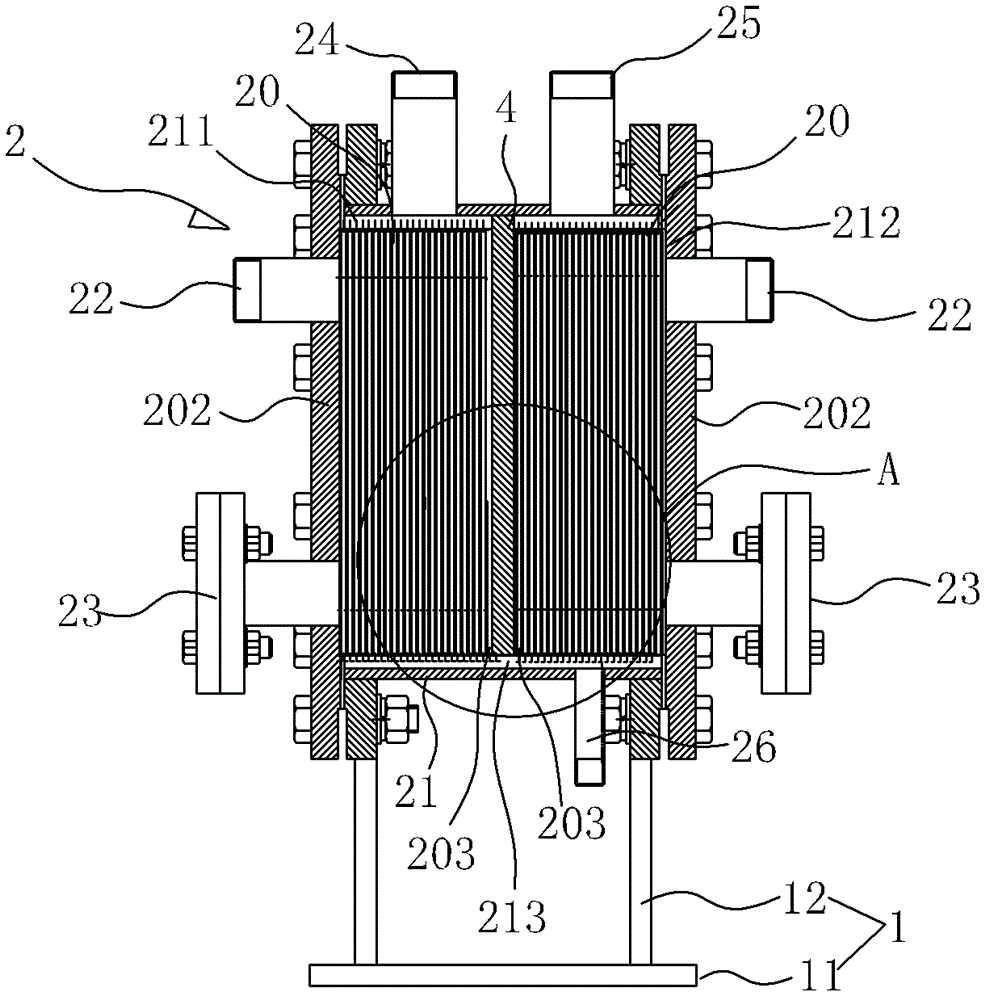

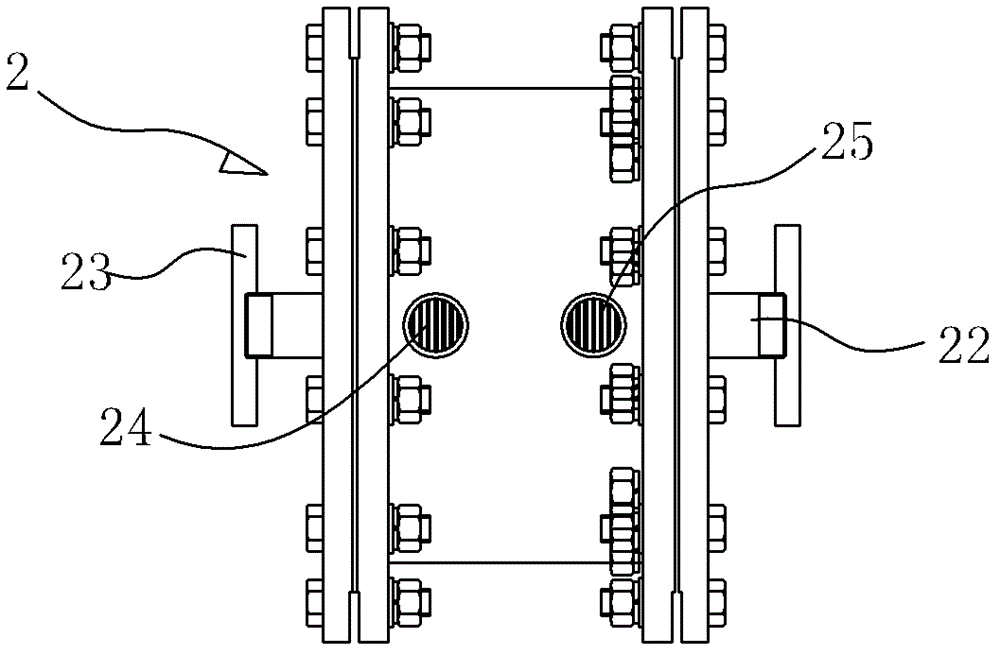

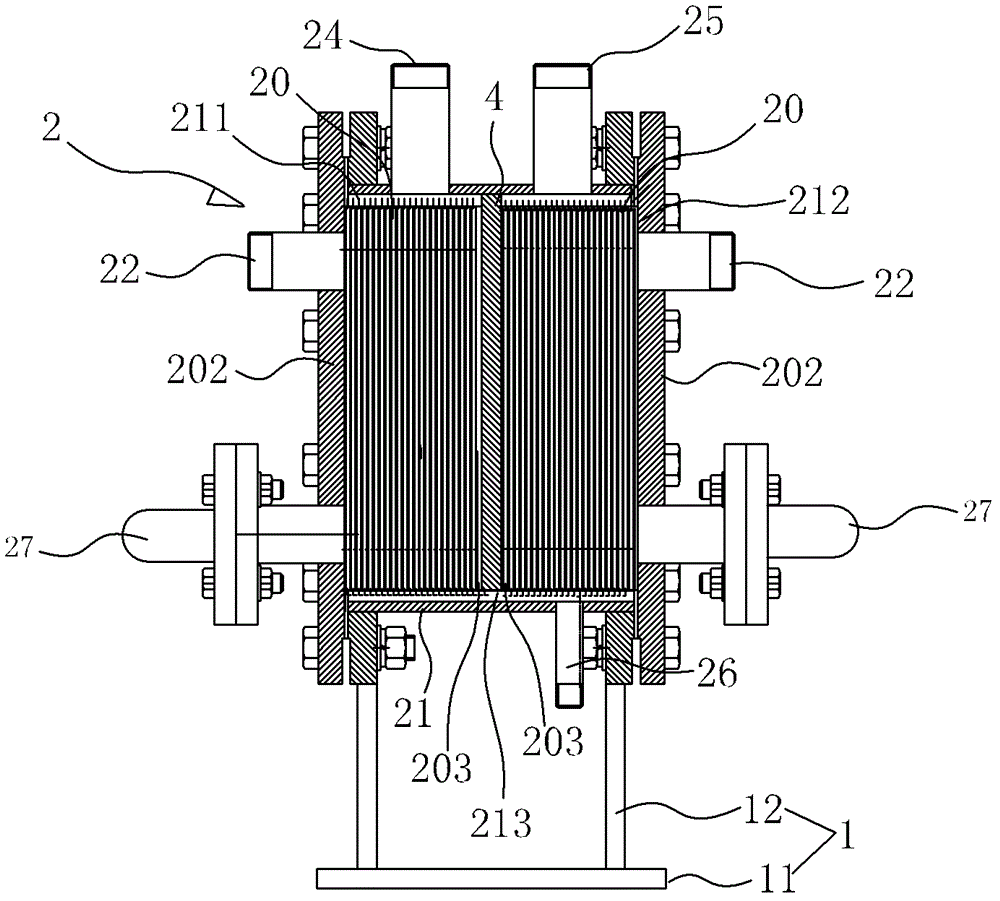

[0050] See Figure 1-14 As shown, a heat exchanger includes: a base 1, the base 1 is used as a bearing device for the entire heat exchanger; a heat exchange assembly 2, the heat exchange assembly 2 includes a A housing 21 with two cavities, two heat exchange cores 20 installed in the cavities of the housing 21 , and a media inlet 22 and a media outlet 23 forming a circulation connection with the heat exchange cores 20 .

[0051] The base 1 includes a horizontal bottom plate 11 and a support plate 12 fixedly welded on the bottom plate 11; The housing 21 falls into the arc-shaped notch and is fixed on the support plate 12 . The bottom plate 11 in the base 1 and the supporting plate 12 fixedly welded on the bottom plate 11 are made of stainless steel 304 or 316, which is durable and has a service life of more than 15 years.

[0052] The inner cavit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com