Light guide plate and backlight module group

A technology of backlight module and light guide plate, applied in optics, light guide, light source and other directions, can solve the problem of increasing the thickness of the frame, and achieve the effect of avoiding lamp shadow, uniform brightness, and shortening the light mixing distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

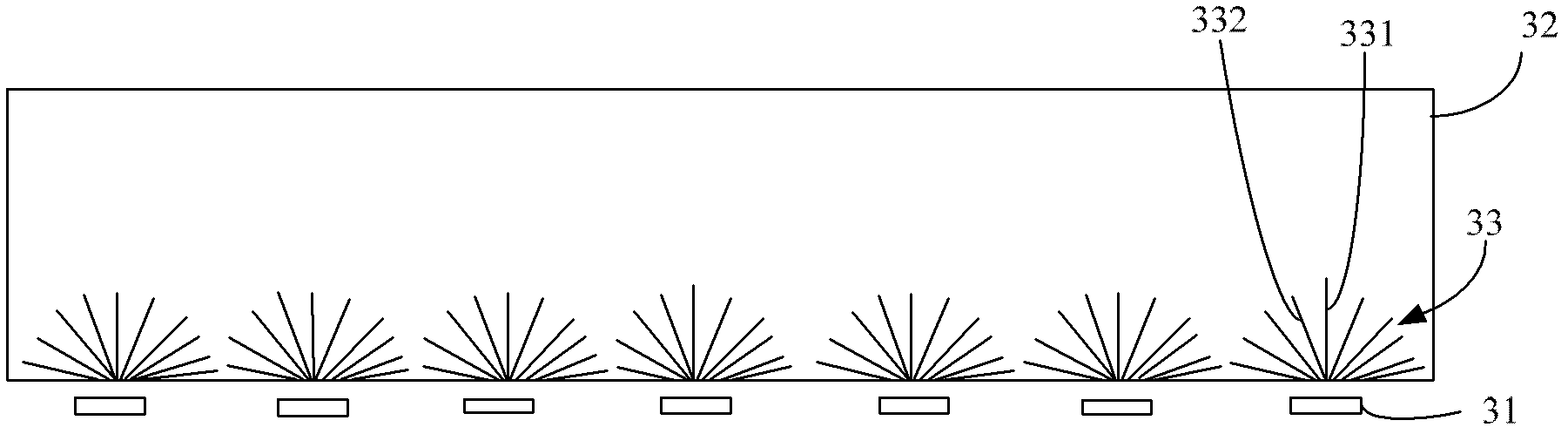

[0023] see image 3 , image 3 It is a structural schematic diagram of the backlight module of the first embodiment of the present invention, such as image 3 As shown, in this embodiment, the backlight module mainly includes a light source 31 and a light guide plate 32 .

[0024] Wherein, there are multiple light sources 31 and they are arranged on the light incident side of the light guide plate 32 . In this embodiment, the light source 31 is an LED light source, including a plurality of LED chips. In other embodiments, the light source 31 may also be any other device capable of emitting light, which is not limited here.

[0025] The light guide plate 32 includes a bottom surface and a top surface opposite to the bottom surface. A plurality of microstructure units 33 are adjacently disposed on at least one of the top surface and the bottom surface of the light guide plate 32 near the light incident side. Wherein, each microstructure unit 33 corresponds to one LED chip, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com