Electromagnetic vibrator vibrating board device and manufacturing method thereof

A technology of electromagnetic vibrator and vibrating plate, applied in the direction of sensors, electrical components, etc., can solve problems such as unbalanced vibration plate stroke, affecting sound quality, etc., and achieve the effect of improving product qualification rate and product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

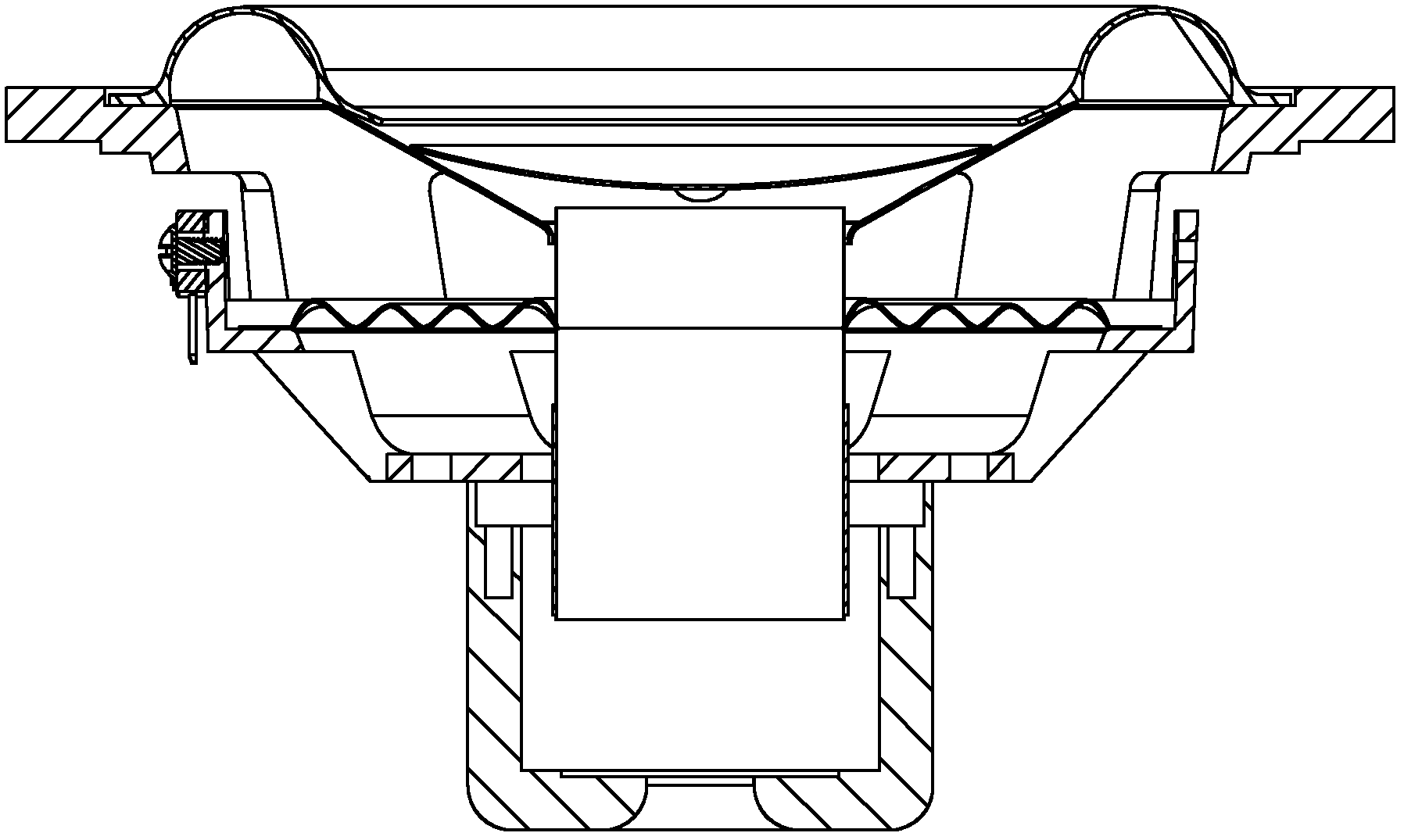

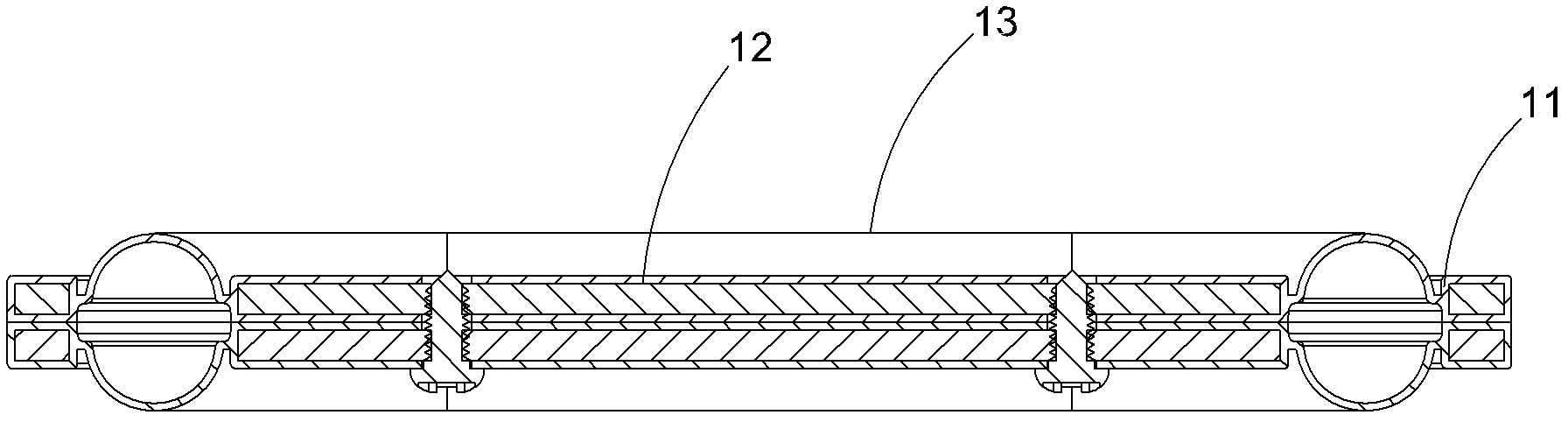

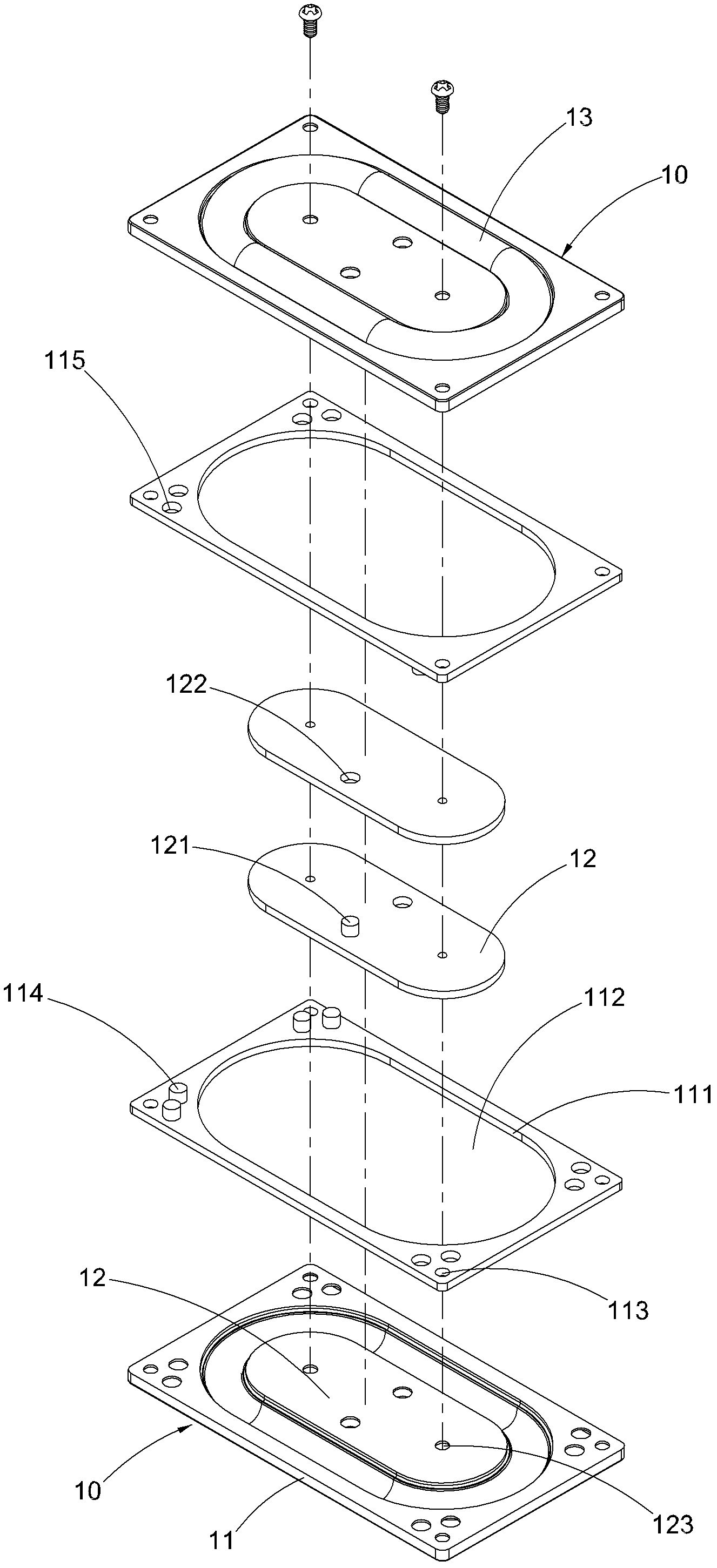

[0044] Please refer to Figure 4 to Figure 5 As shown, a vibrating plate device of an electromagnetic vibrator, the vibrating plate device can also be formed by using the above-mentioned vibrating plate module 10 and the lower hanging edge 20, the lower hanging edge 20 and the upper hanging edge of the vibrating plate module 10 The side 13 is in the opposite direction. The inner edge of the hanging side 20 is connected and fixed with the periphery of the lower surface of the vibrating plate 12 , and the outer edge is fixed on the base 11 .

[0045] Further, the central position of the lower surface of the vibrating plate 12 is provided with a voice coil fixing portion 124 for fixing one end of the voice coil of the electromagnetic vibrator on the vibrating plate 12;

[0046] Further, a number of ribs 125 are evenly distributed on the vibrating plate 12, and the ribs 125 take the voice coil fixing part 124 as the center and radially spread around the voice coil fixing part 124;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com