Adhesive tape for surface protection

A technology of adhesive tape and adhesive, which is applied in the direction of film/sheet adhesive, adhesive, transportation and packaging, etc. It can solve the problems of poor common substrates, etc., and achieve the prevention of adhesive adhesion and excellent anchoring Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

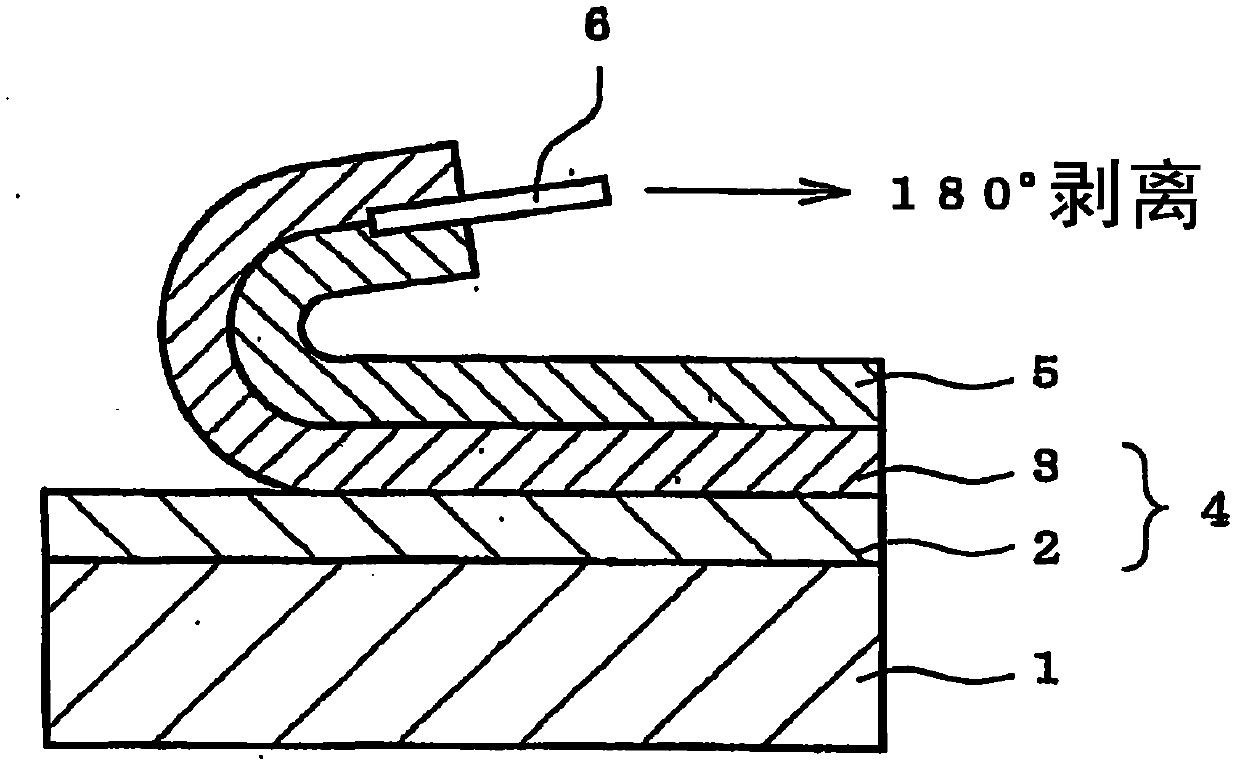

[0108] The adhesive tape of the present invention may assume any of a form in which a long tape is wound into a roll, a form in which cut pieces of a long tape of an appropriate size are stacked.

[0109] The adhesive tape of the present invention may have a release agent layer to protect the adhesive layer. For example, the adhesive tape of the present invention may have a release agent layer on the substrate on the side opposite to the adhesive layer (ie, "adhesive layer / substrate / release agent layer" configuration). In this configuration, the release agent layer is sometimes referred to as a back coating, and the adhesive tape is sometimes referred to as an adhesive tape with a back coating.

[0110] In order to protect the adhesive layer of the adhesive tape of the present invention, a release material having a release agent layer formed on its base material may be used. Specifically, by bringing the adhesive layer of the adhesive tape of the present invention into contac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com