Small natural gas desulfurization device and desulfurization method thereof

A desulfurization device and natural gas technology, applied in the direction of gas fuel, petroleum industry, fuel, etc., can solve the problems of resource waste and high cost, and achieve the effect of easy transformation and processing, wide application range and good removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

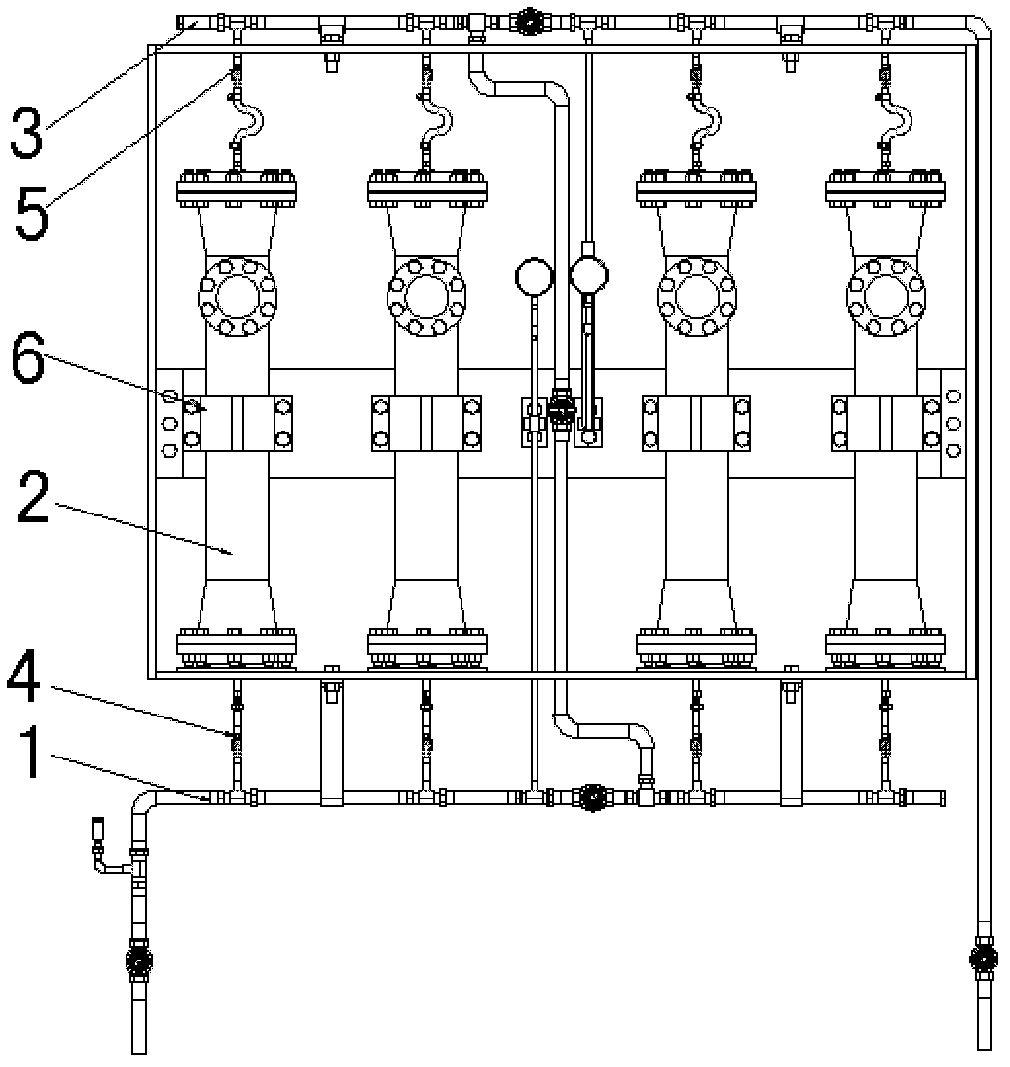

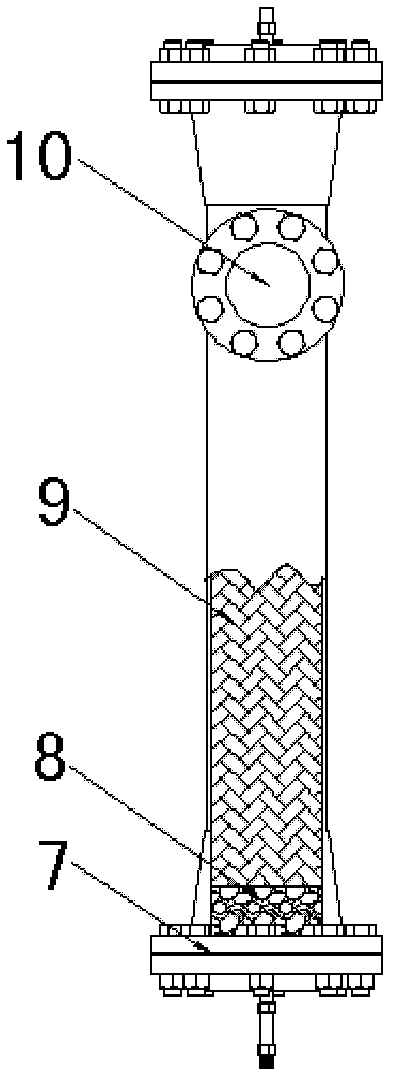

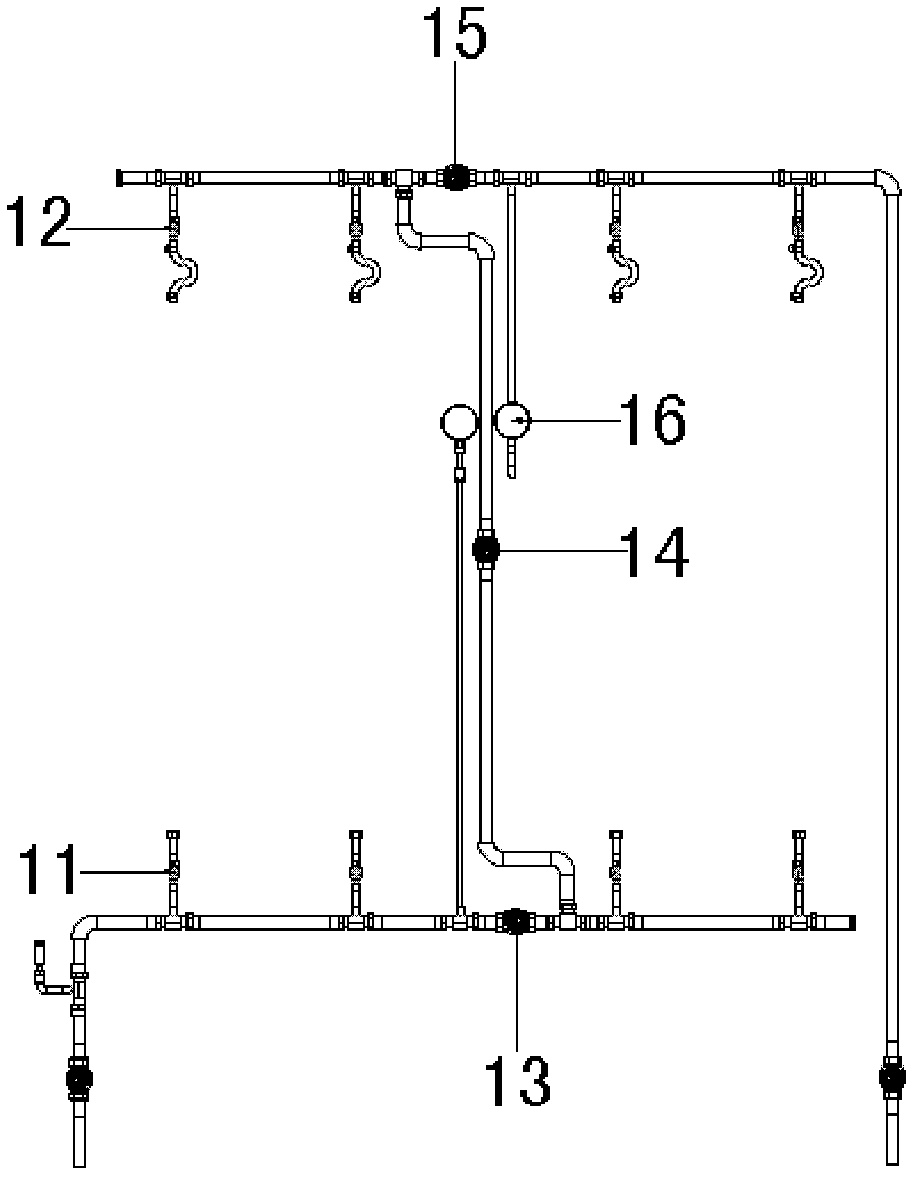

[0032] Such as figure 1 As shown, the raw natural gas enters the device from the needle cut-off valve located at the bottom, because H 2 S is denser than CH 4 , to increase its passage time, so that the desulfurization reaction is sufficient; because the Fe used in the subsequent desulfurization reaction 2 o 3 It is easy to pulverize and harden when it meets water, and block the nozzle to cause high-pressure rupture. Therefore, a safety valve is installed at the air inlet of the device. Bracket 6 is composed of upper, middle and lower support plates; a rubber gasket is installed on the lower support plate, which can offset the docking error in the installation of each desulfurization bottle, and at the same time, the lower part of the plate is equipped with an air intake pipe support; In addition to the instrument pipe support, the middle support plate is also equipped with multiple sets of pipe fixing parts to limit the horizontal displacement of the desulfurization tank a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com