Antimony-added high-tin bronze alloy rod for high-speed railway equipment and manufacturing method thereof

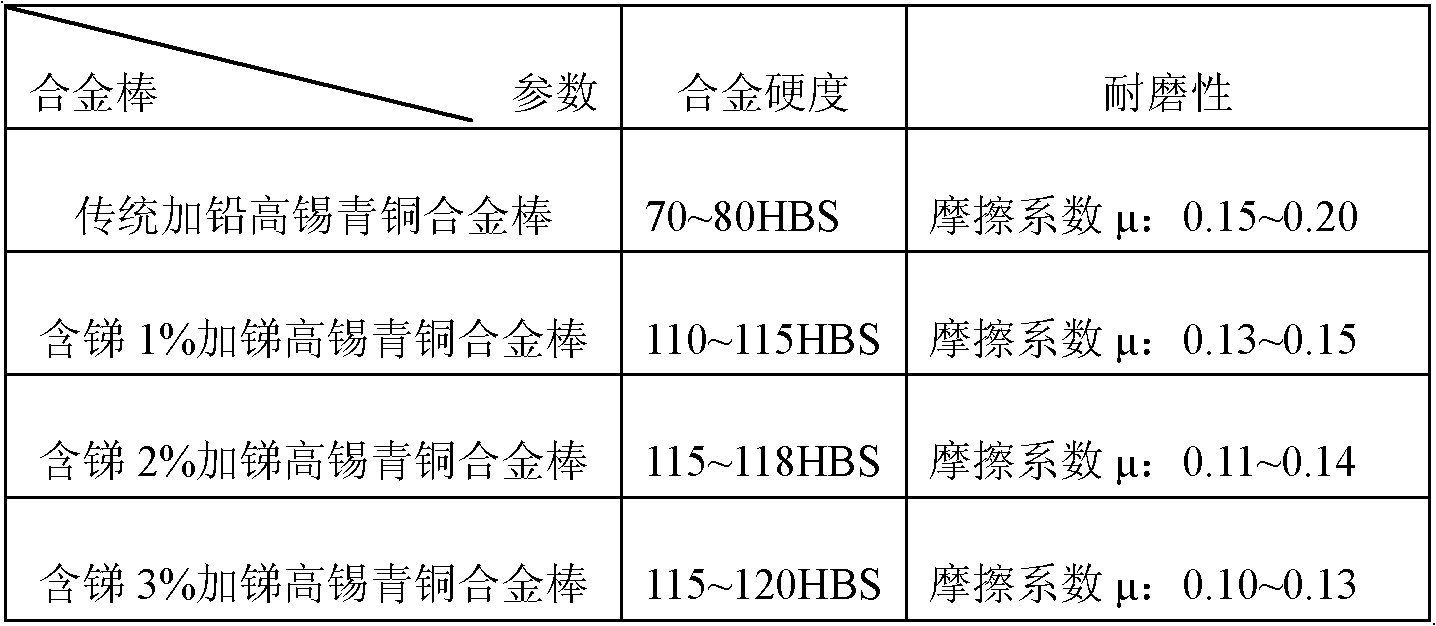

A technology of adding antimony, high tin and bronze alloys, which is applied in the direction of manufacturing tools, casting molding equipment, metal processing equipment, etc., can solve problems such as environmental impact and failure to meet requirements, and achieve improved wear resistance, environmental protection performance, and improved alloy quality. The effect of hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] An antimony-added high-tin bronze alloy for high-speed railway equipment and an antimony-added high-tin bronze alloy rod made of the alloy. The components of the alloy are composed by weight percentage: 1% antimony, 8% tin, and 91% copper .

[0045] The preparation method of the antimony-added high-tin bronze alloy rod for the above-mentioned high-speed railway equipment comprises the following steps:

[0046] i. Place electrolytic copper, tin, and antimony in a power frequency electric furnace according to the ratio of 1% antimony, 8% tin, and 91% copper, heat to 1200°C-1250°C to completely melt, and then keep warm to 1230°C;

[0047] ii. Use a special graphite tool to fully stir the completely melted alloy liquid, and then cover it with high-purity scaly graphite powder to prevent its oxidation. The thickness of the graphite powder is about 15-25mm;

[0048] iii. After 25-30 minutes of heat preservation, heat up to 1350 degrees again, and turn on the vibration device...

Embodiment 2

[0057] An antimony-added high-tin bronze alloy for high-speed railway equipment and an antimony-added high-tin bronze alloy rod made of the alloy. The components of the alloy are composed of 2% antimony, 9% tin, and 89% copper by weight percentage .

[0058] The preparation method of the antimony-added high-tin bronze alloy rod for the above-mentioned high-speed railway equipment comprises the following steps:

[0059] i. Place electrolytic copper, tin, and antimony in a power frequency electric furnace according to the ratio of 2% antimony, 9% tin, and 89% copper, heat to 1200°C-1250°C to completely melt, and then keep warm to 1230°C;

[0060] ii. Use a special graphite tool to fully stir the completely melted alloy liquid, and then cover it with high-purity scaly graphite powder to prevent its oxidation. The thickness of the graphite powder is about 15-25mm;

[0061] iii. After 25-30 minutes of heat preservation, heat up to 1350 degrees again, and turn on the vibration devi...

Embodiment 3

[0070] An antimony-added high-tin bronze alloy for high-speed railway equipment and an antimony-added high-tin bronze alloy rod made of the alloy. The components of the alloy are composed by weight percentage: 3% antimony, 10% tin, and 87% copper .

[0071] The preparation method of the antimony-added high-tin bronze alloy rod for the above-mentioned high-speed railway equipment comprises the following steps:

[0072] i. Place electrolytic copper, tin, and antimony in a power frequency electric furnace according to the ratio of 3% antimony, 10% tin, and 87% copper, heat to 1200°C-1250°C to completely melt, and then keep warm to 1230°C;

[0073] ii. Use a special graphite tool to fully stir the completely melted alloy liquid, and then cover it with high-purity scaly graphite powder to prevent its oxidation. The thickness of the graphite powder is about 15-25mm;

[0074] iii. After 25-30 minutes of heat preservation, heat up to 1350 degrees again, and turn on the vibration devi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com