Fowl egg mass center detecting method

A determination method and technology for poultry eggs, which are applied in the field of determination of characteristic parameters of objects, can solve problems such as no relevant literature reports, and achieve the effects of less measurement parameters and simple calculation methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

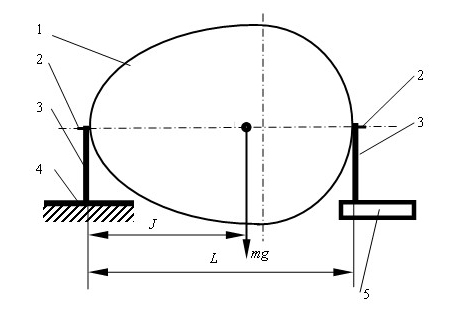

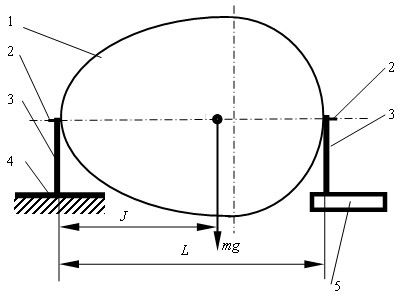

[0017] Take 200 fresh grass eggs and measure their maximum major axis diameter with a digital display vernier caliper L , use an electronic balance to measure the mass m of the poultry egg; use an electronic balance to measure the mass m of the supporting point 1 ; Fix the special support parts to the end points of 200 grass eggs with glue, then place 200 grass eggs on the special support frame respectively, and keep the support level, and measure the quality m of the support point by electronic balance 1 ; Use the formula to calculate the distance J from the center of mass to the endpoint of the small end. The average centroid position of 200 grass eggs is 26.52±1.52 (mm), which is the same as the maximum major axis diameter L The ratio is 0.49±0.02 (the centroid of the grass egg is approximately at the midpoint of its long diameter).

Embodiment 2

[0019] Take 200 foreign eggs and measure their maximum major axis diameter with a digital display vernier caliper L , use an electronic balance to measure the mass m of the poultry egg; use an electronic balance to measure the mass m of the supporting point 1 ; Fix the special support parts to the end points of the big and small ends of 200 foreign eggs with glue, then place the 200 foreign eggs on the special support frame respectively, and keep the support level, measure the quality m of the support point by electronic balance 1 ; Use the formula to calculate the distance J from the center of mass to the endpoint of the small end. The average centroid position of 200 foreign eggs is 27.61±1.60 (mm), which is the same as the maximum major axis diameter L The ratio is 0.48±0.02 (the center of mass of foreign chicken eggs is approximately at the midpoint of its long diameter).

Embodiment 3

[0021] Take 200 fresh duck eggs and measure the maximum major axis diameter with a digital display vernier caliper L , use an electronic balance to measure the mass m of the poultry egg; use an electronic balance to measure the mass m of the supporting point 1 ; Fix the special support piece on the end points of the big and small heads of 200 duck eggs with glue, then place 200 duck eggs on the special support frame respectively, and keep the support level, measure the quality m of the support point by electronic balance 1 ; Use the formula to calculate the distance J from the center of mass to the endpoint of the small end. The average centroid position of 200 duck eggs is 28.20±1.80 (mm), which is the same as the maximum major axis diameter L The ratio is 0.48±0.02 (the center of mass of the duck egg is approximately at the midpoint of the long diameter of the egg).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com