Hydraulic performance measuring method and apparatus for heat distribution pipe network

A heat pipe network and measurement method technology, applied in the direction of measuring devices, measuring heat, calorimeters, etc., can solve the problems of insufficient initial adjustment of the system, energy waste, hydraulic imbalance, etc., achieve less measurement parameters, eliminate cold and hot uniformity , the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

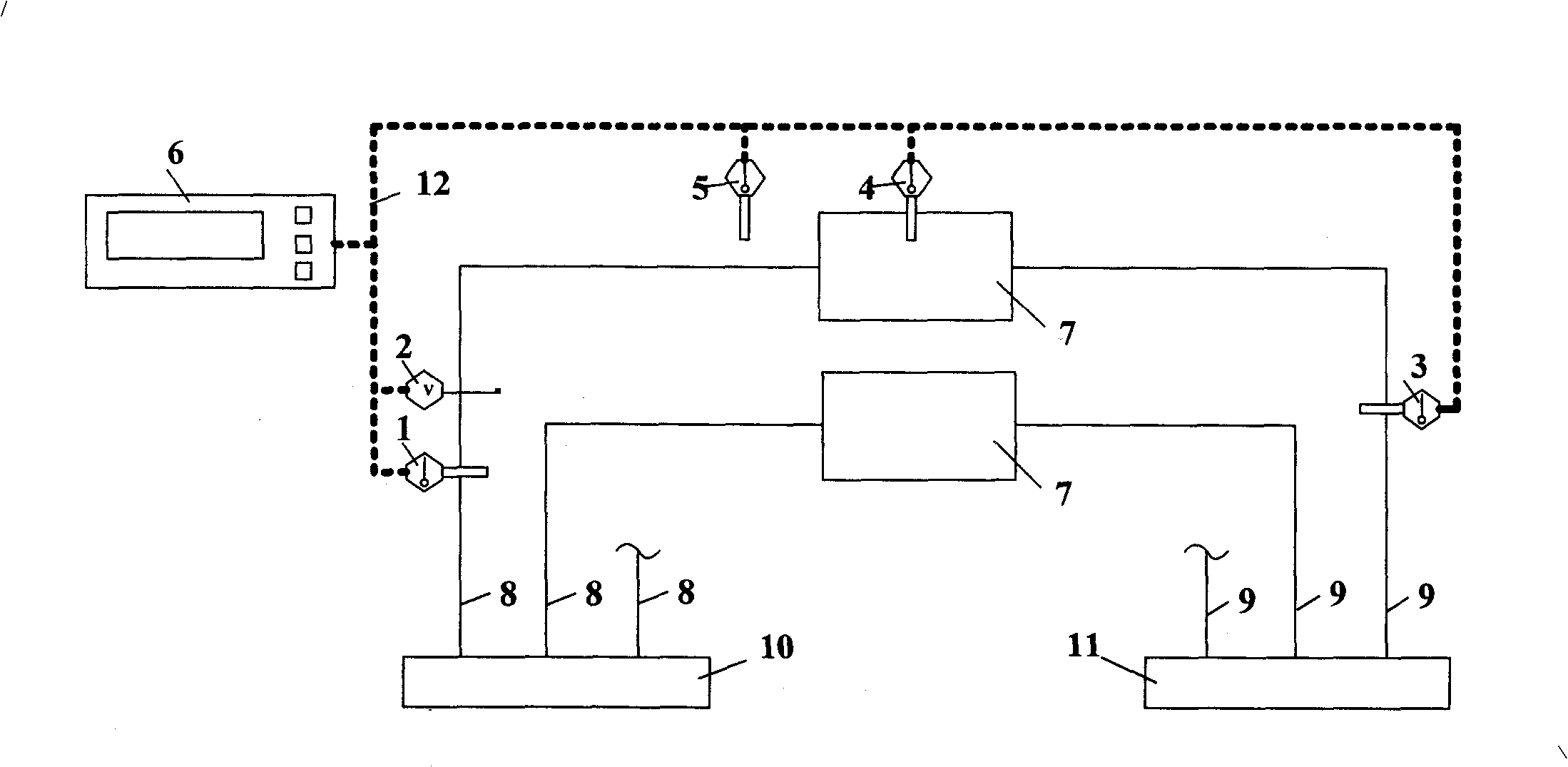

[0029] see figure 1 , is a schematic diagram of a specific embodiment of the hydraulic condition measuring device of the heat pipe network according to the present invention. The heat pipe network in the heating system includes a plurality of heat users 7, a plurality of heat pipe network water supply pipes 8, a plurality of heat pipe network return pipes 9, one end of the multiple heat pipe network water supply pipes 8 and a water distributor 10 The other end is connected to the heat user 7; one end of the multiple heat pipe network return pipes 9 is connected to the heat user 7, and the other end is connected to the water collector 11.

[0030] The method for measuring hydraulic conditions of the heat pipe network of the present invention is:

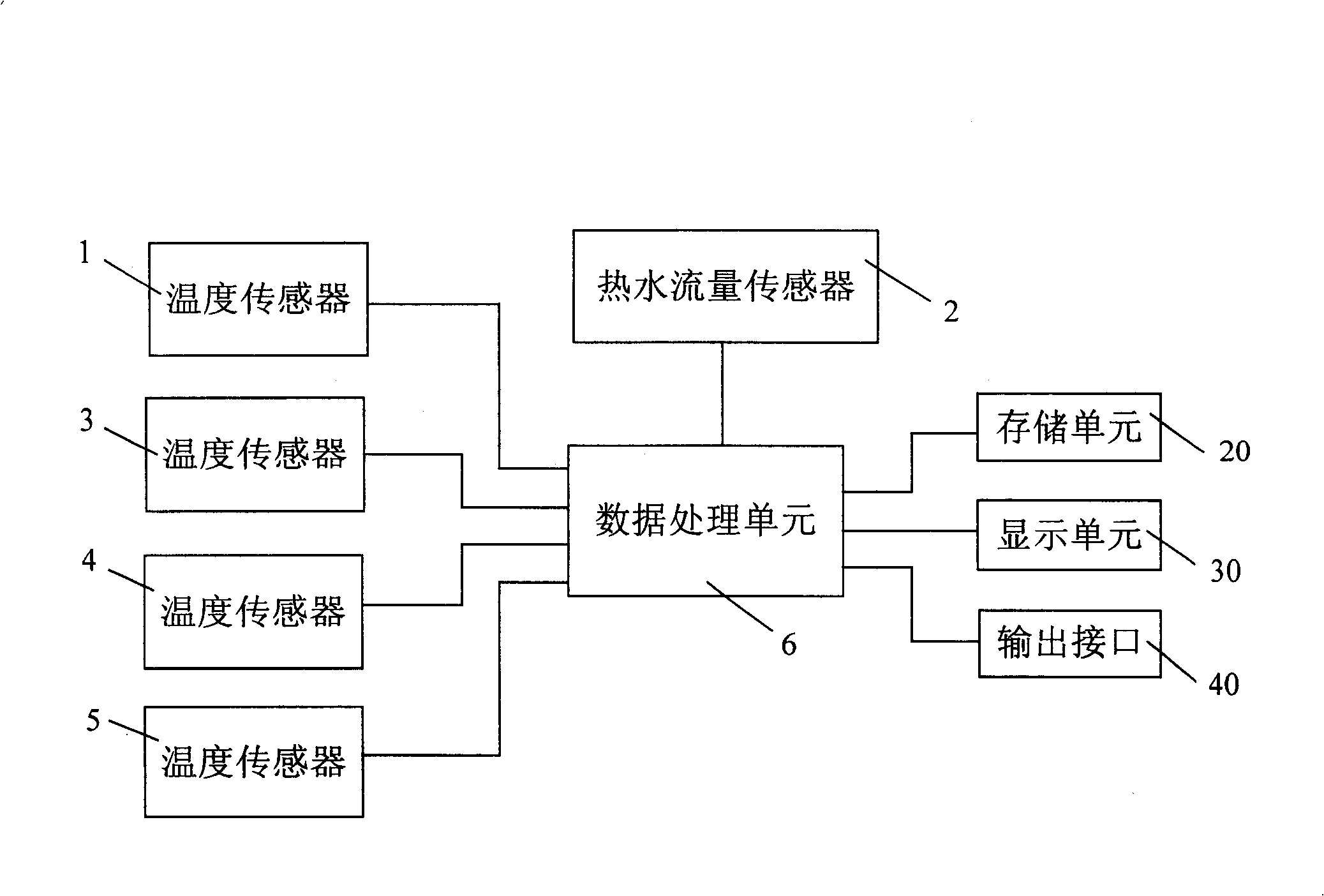

[0031] First, at the entrance of each thermal branch of the thermal pipe network, that is, a te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com