Neutron detector based on polyethylene combined gas scintillator

A neutron detector and gas scintillation technology, applied in the field of detectors, can solve the problems of low neutron/gamma resolution, fast neutron energy response is not very flat, difficult to achieve fast neutron/gamma Effects of horse resolution, flat neutron spectral response, and fast time response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

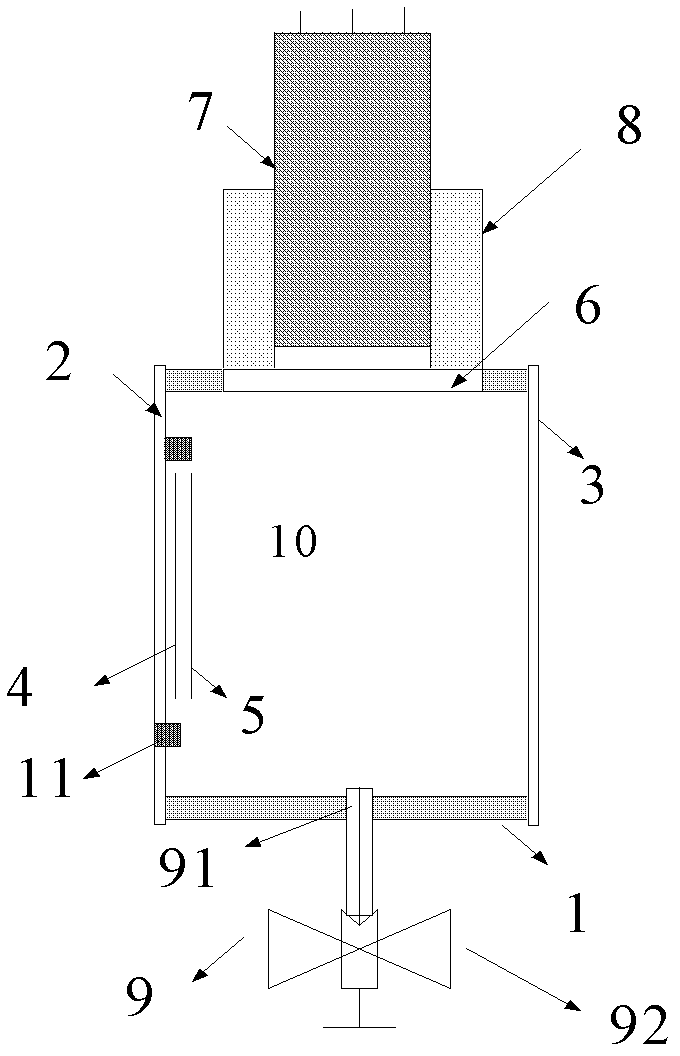

[0025] Such as figure 1 As shown, the neutron detector based on polyethylene combined gas scintillator in the present invention includes a cylinder body 1, an incident window 2 sealed and arranged on the front end surface of the cylinder body 1, an exit window 3 sealed and arranged on the rear end surface of the cylinder body 1, The first conversion target 4 and the second conversion target 5 fixed on the entrance window 2, the quartz window 6 arranged on the side of the cylinder body 1, the sleeve 8 fixed on the quartz window 6, the photoelectric detector installed in the sleeve 8 Device 7, an inflator 9 connected with the cylinder body 1, and an air filling device inside the cylinder body 4 He scintillation gas 10, pressure ring 11 that compresses the first conversion target 4 and the second conversion target 5; the incident window 2 and the exit window 3 at the front and rear ends of the cylinder body 1 are titanium alloy plates with a thickness of 0.4mm; the scintillation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com