Low-resistance syringe

A low-resistance syringe and syringe technology, applied in the directions of syringes, hypodermic injection devices, infusion sets, etc., can solve problems such as inability to achieve sealing, and achieve the effects of low resistance, structural optimization, and consistent extrusion pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

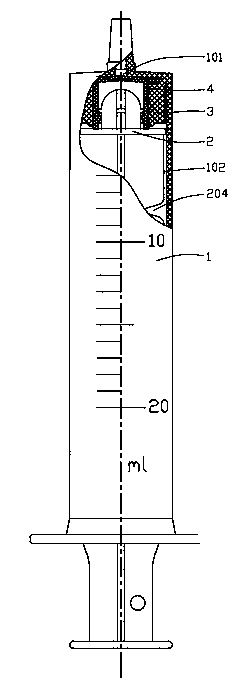

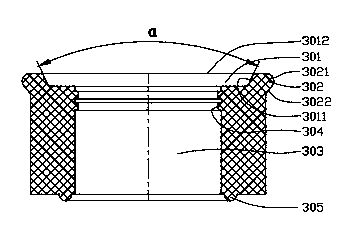

[0018] see figure 1 , a low-resistance syringe, comprising a casing 1 and a push rod 2 slidably connected in the casing 1 . A piston 3 is connected to the head end of the push rod 2 through a connecting head 4 . The piston 3 is in sealing and sliding connection with the inner hole of the outer casing 1, and a front cavity 101 at the front end of the piston 3 and a rear cavity 102 at the rear end of the piston 3 are formed in the inner hole of the outer casing 1 .

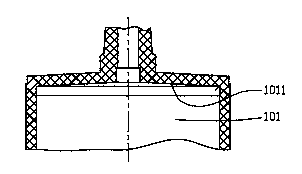

[0019] see figure 2 and Figure 4 , There is a front cavity end surface 1011 in the front cavity 101 of the jacket, and an injection outlet is arranged in the middle of the end surface. The front cavity end surface 1011 is a conical surface with a large cone angle. A pressure plate end surface 4012 is also provided at the front end of the connecting head 4 , and the pressure plate end surface 4012 is provided with a tapered surface matched with the front cavity end surface 1011 . After the push rod 2 is pushed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com