A kind of semi-automatic riveting press for rubber hose joint and its operation method

A rubber hose joint, semi-automatic technology, applied in the field of presses, can solve the problems of poor sealing performance between the rubber hose and the joint, different riveting pressure, etc., and achieve the effects of reducing the amount of manual labor, consistent extrusion force, and uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to better explain the present invention and facilitate understanding, the present invention will be described in detail below with reference to the accompanying drawings and through specific embodiments.

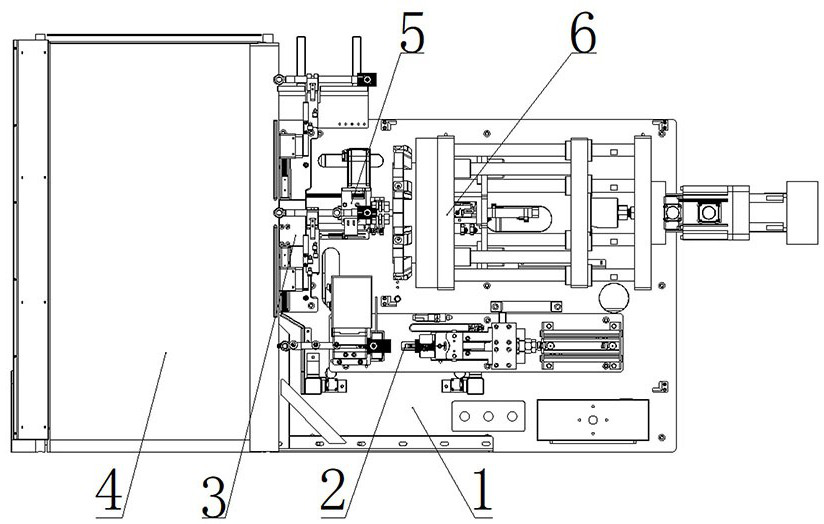

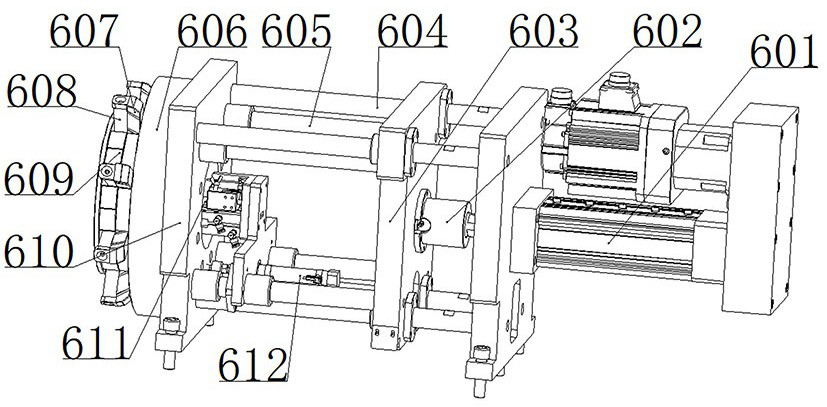

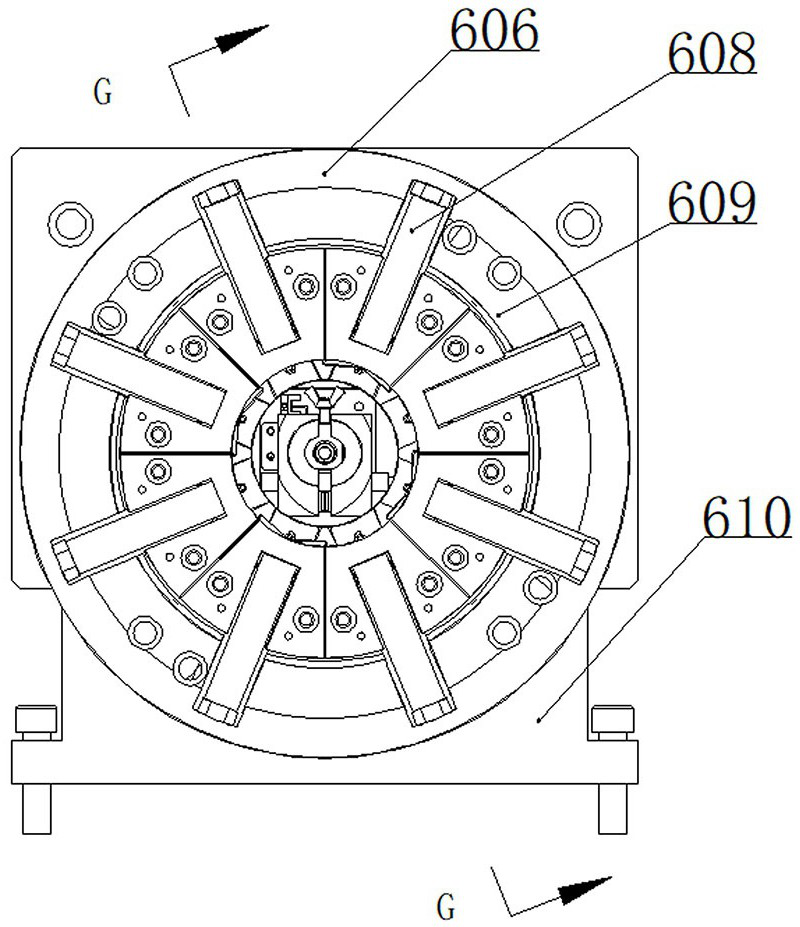

[0038] like figure 1As shown, the present invention provides a semi-automatic riveting and pressing machine for rubber hose joints, including a worktable 1 , a plug-in mechanism 2 , a turning mechanism 3 , a moving mechanism 5 and a riveting and pressing mechanism 6 . Wherein, the plug-in mechanism 2 is placed on the upper side of the workbench 1 and arranged along the lateral direction of the workbench 1 . The other side of the worktable 1 is provided with a turning mechanism 3, a moving mechanism 5 and a riveting and pressing mechanism 6 in sequence. . The plug-in mechanism 2 is used to plug the connector on the hose. The turning mechanism 3 is used to turn the rubber tube around the lateral direction of the workbench 1, so that the rubber tube can be tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com