An improved environmental protection and high-efficiency fully automatic plate washing machine movement device

A moving device and fully automatic technology, which is applied in the field of enzyme label washer, can solve the problems of washing liquid loss and waste, automatic plate washer not automatic, etc., and achieve the effect of preventing cross-infection, easy to control, efficient and fully automatic plate washing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The implementation of the present invention will be further described below in conjunction with the accompanying drawings, but the implementation of the present invention is not limited thereto.

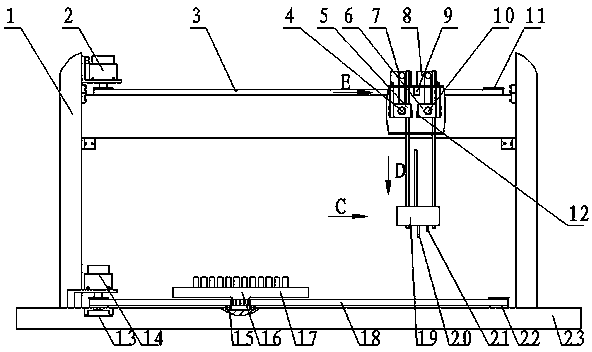

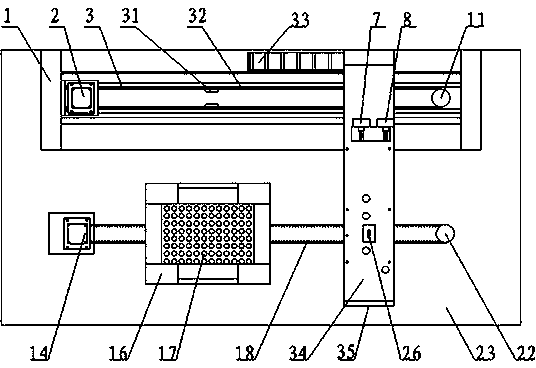

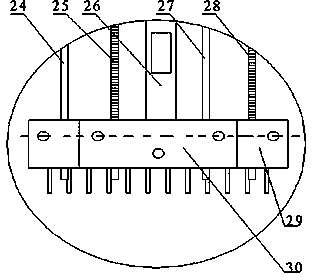

[0021] like figure 1As shown, it is the front view of the moving device of the improved environmental protection and high-efficiency automatic plate washing machine. The double-row compound cleaning head 19 is a cleaning head with twelve needles in each row. The short needle is the injection needle row 21, and the twenty-four needles are fixed on the rectangular plastic block. The sixteen needles in the middle of the double-row composite cleaning head 19 are the double-row composite cleaning head B part 30, and the sixteen needles are fixed on the plastic block by solid glue. On the rectangular plastic block in the middle, there is a first liquid injection channel 38 and a first liquid suction pipe 37 in the plastic block, and the remaining eight needles are double-row compoun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com