Grinding fluid filtering device for polishing machine

A filter device and sweeping machine technology, applied in grinding/polishing safety devices, filtration separation, gravity filters, etc., can solve the problem of inability to realize automatic filtration of grinding fluid, poor filtering of impurities, and grinding fluid filtration efficiency Low-level problems, to achieve the effect of saving labor costs, improving yield rate, and exquisite structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

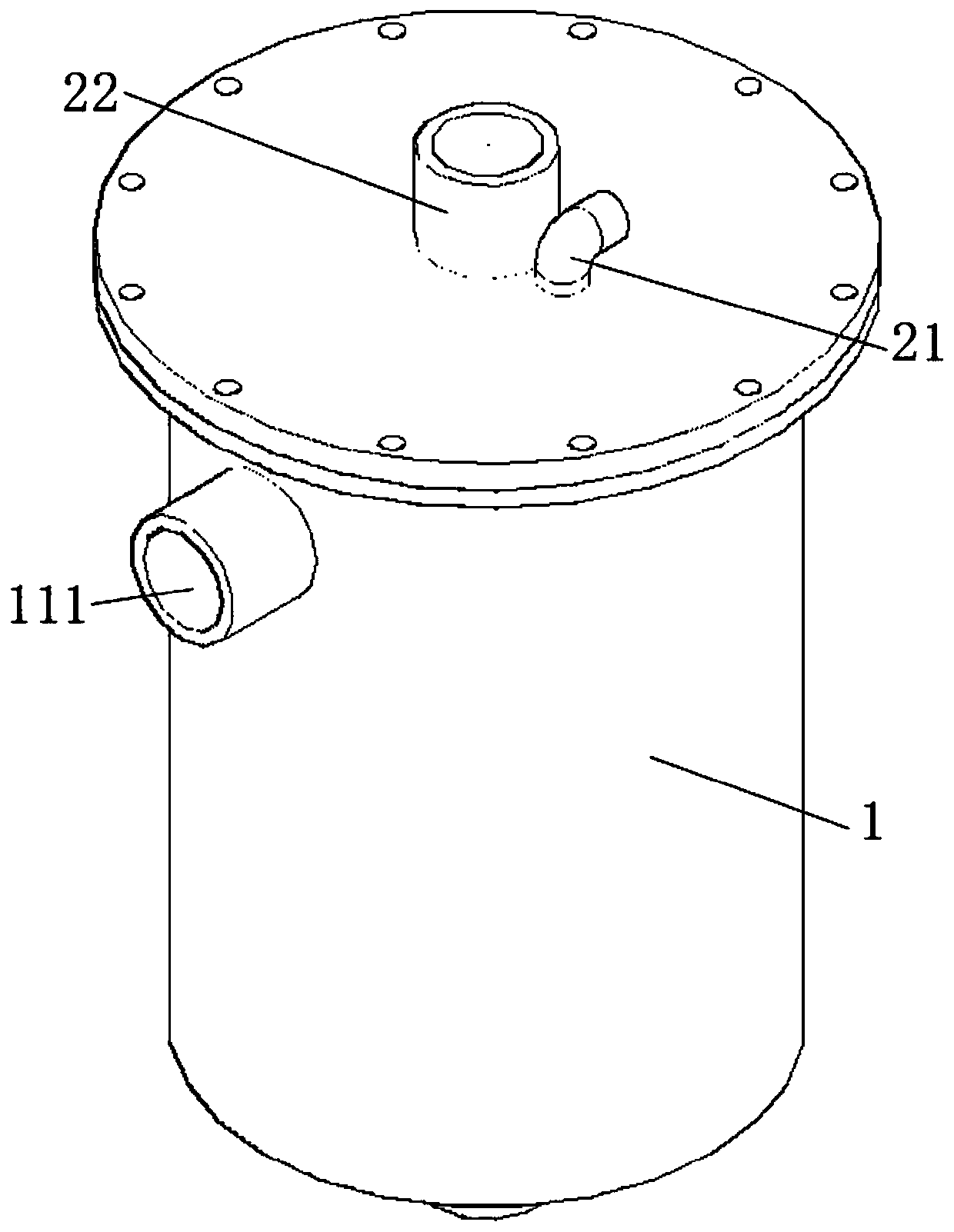

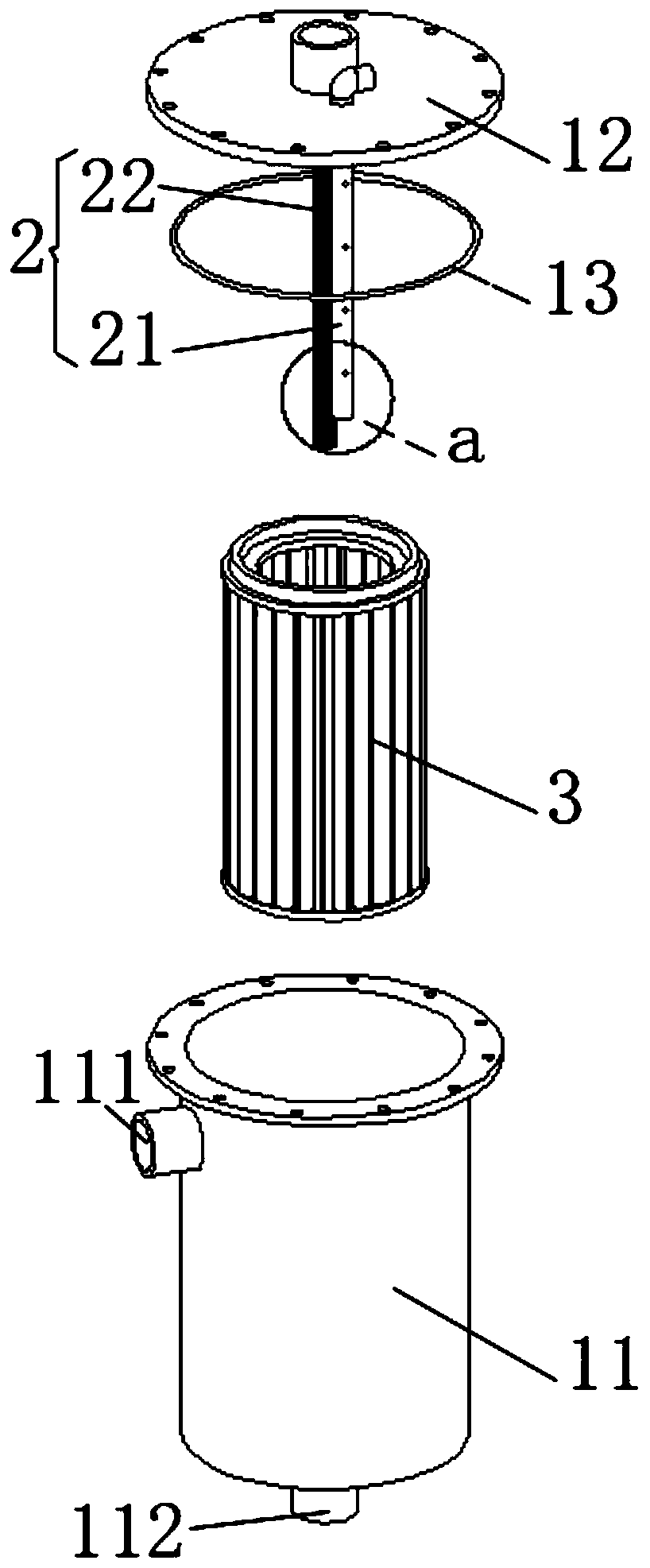

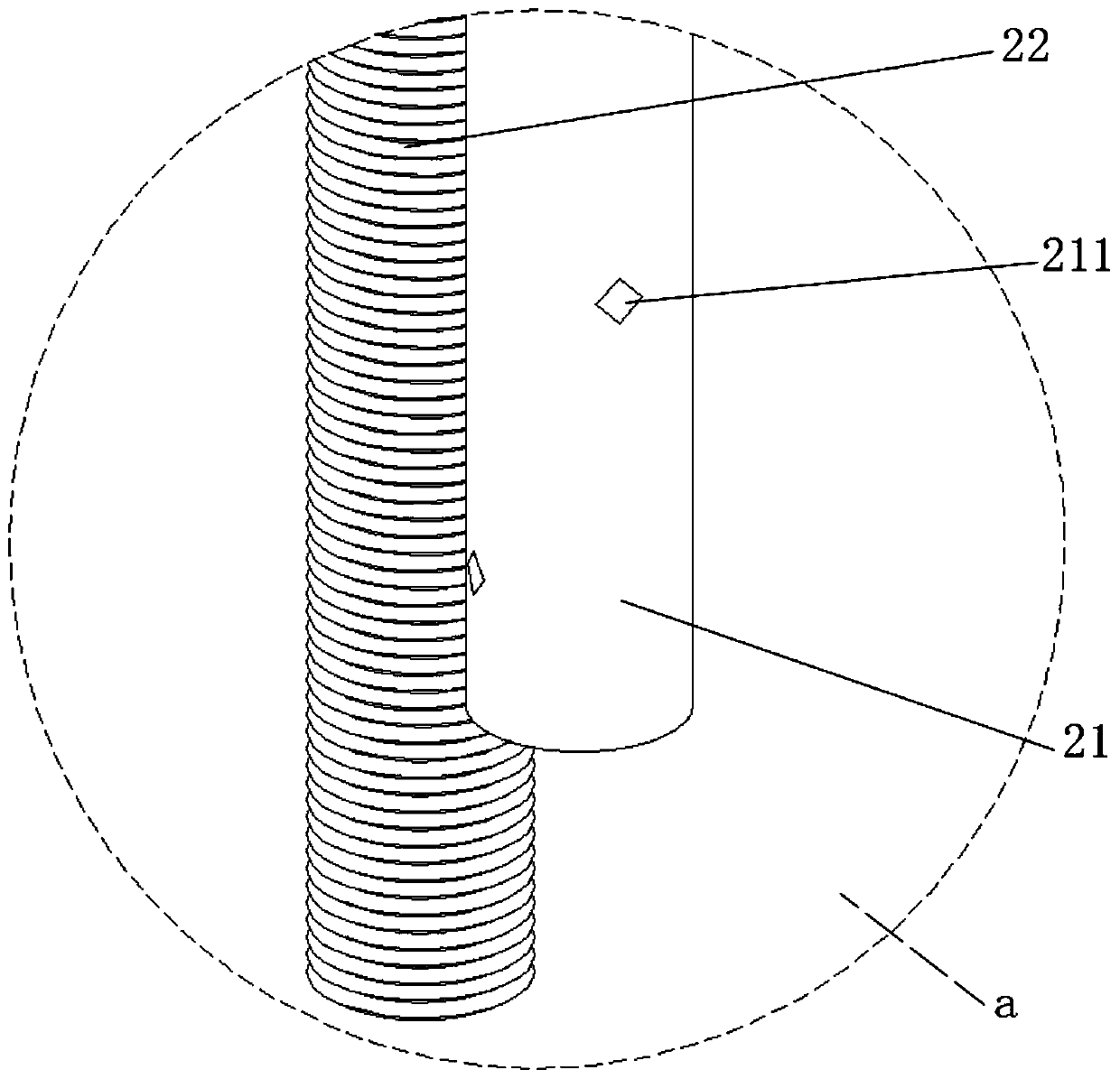

[0024] refer to Figure 1 to Figure 4 As shown, the present invention provides a grinding fluid filter device for a sweeping machine. The present invention includes: a filtering device body 1, a filtering mechanism and a filtering pipeline 2; the filtering device body 1 is externally connected with a grinding liquid recovery device and a drainage device; the filtering mechanism is arranged inside the filtering device body 1; One end of the filter pipeline 2 is arranged inside the filter mechanism, and the other end of the filter pipeline 2 passes through the filter body 1, and is respectively connected with the high-pressure air blowing device, the water supply device and the sweeping machine on the sweeping machine during application. The cooling device is connected; the filter body 1 is used to accommodate the grinding liquid, the filter m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com