Carryable shelf warehousing system based on automatic carry trolley

A technology of automatic handling trolleys and storage systems, applied in the field of logistics storage systems, can solve the problems of high management costs and high labor costs of picking personnel, and achieve the effect of simple system and optimized settings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

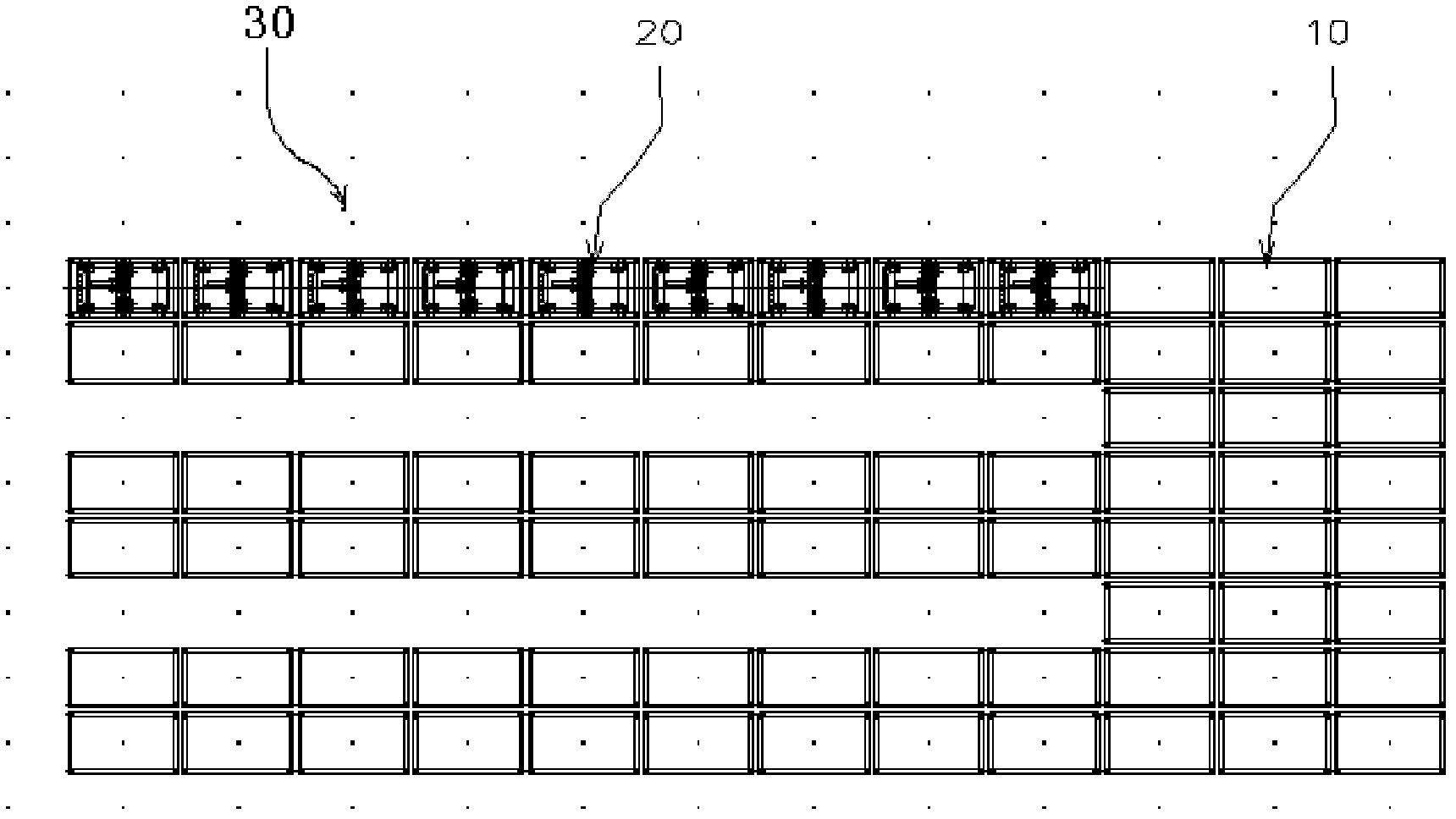

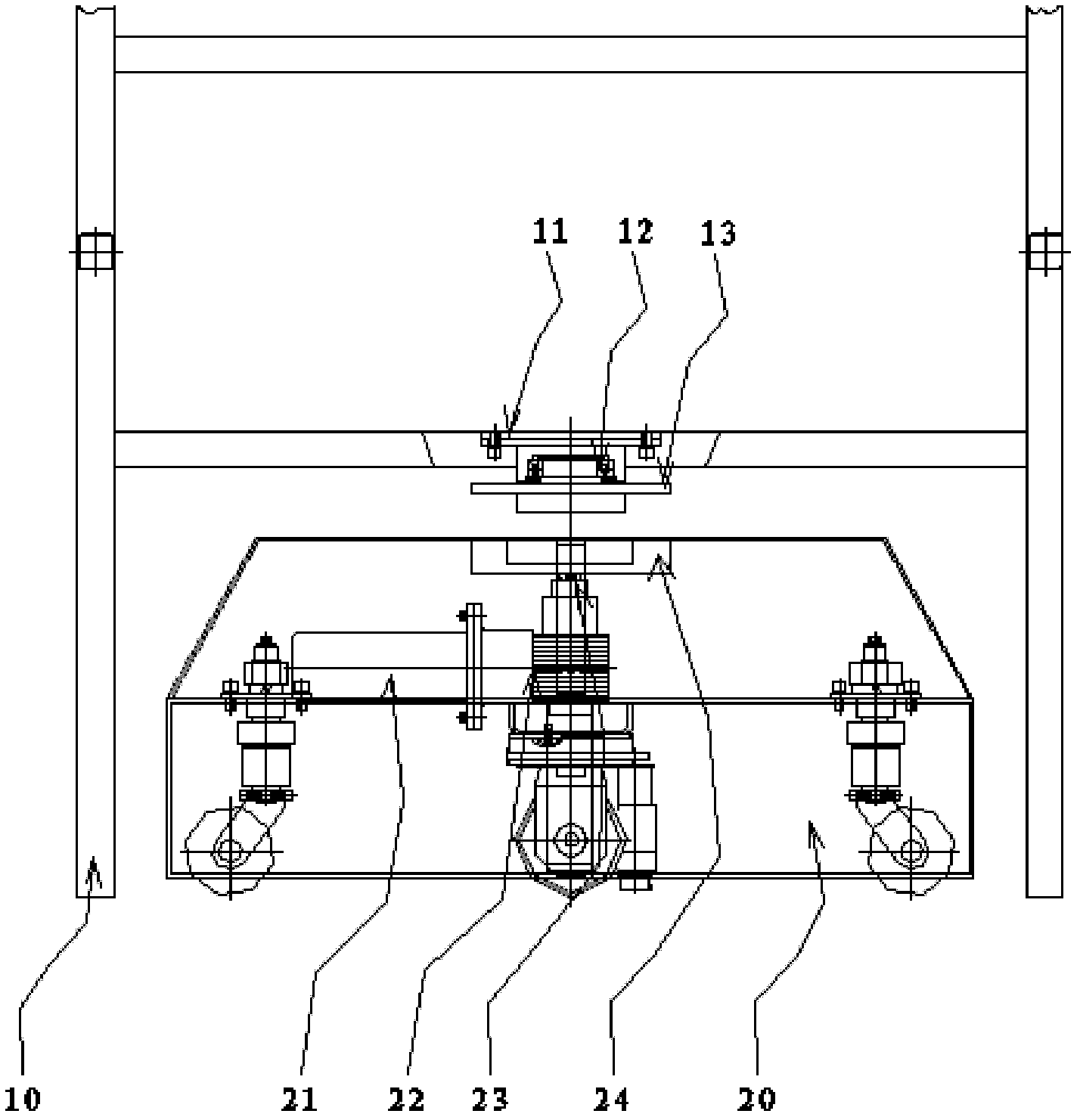

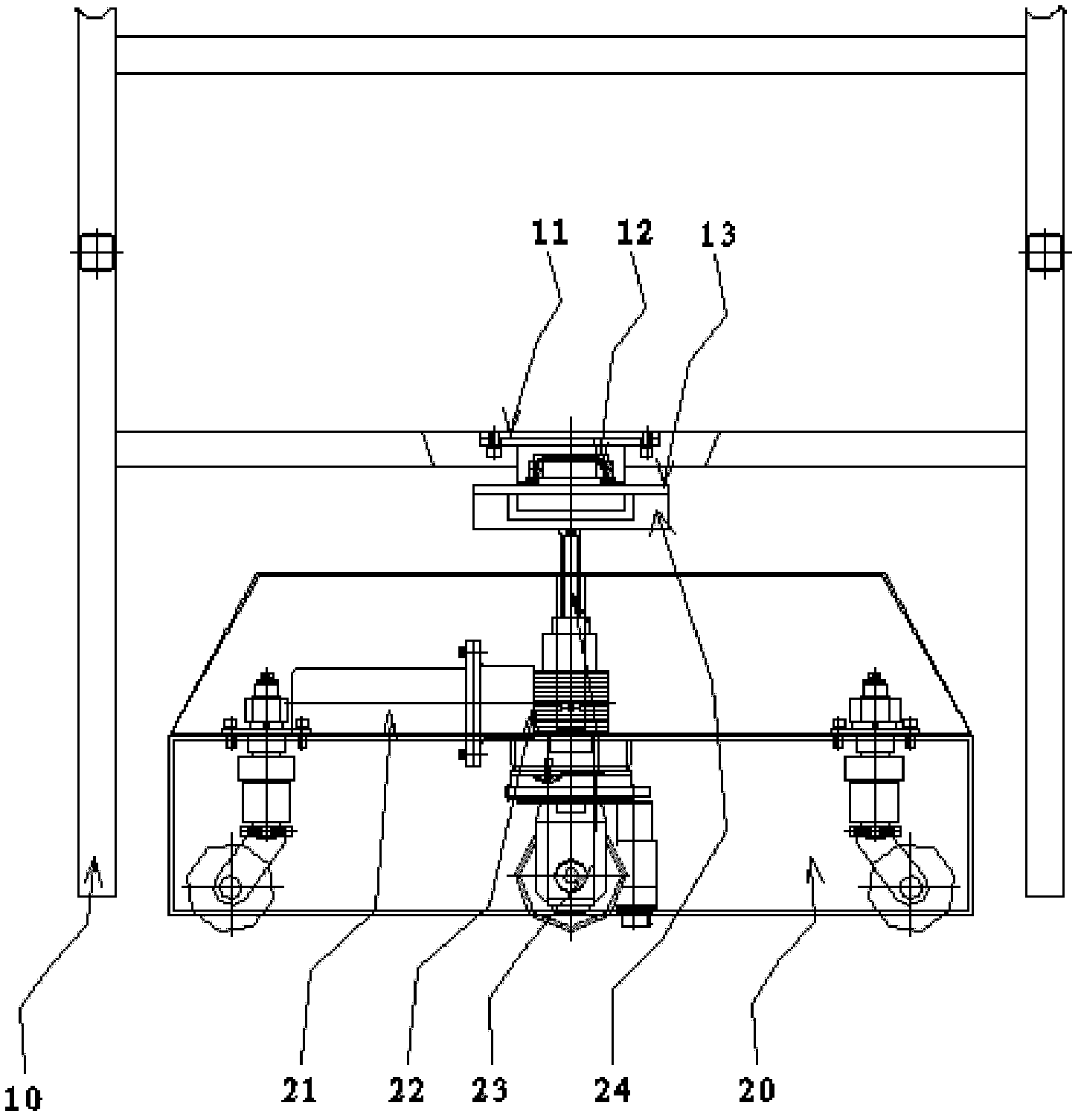

[0084] like Figure 1 to Figure 5 Shown is a plan layout of a transportable shelf storage system based on an automatic transport trolley. The transportable shelf storage system based on an automatic transport trolley of the present invention includes a transportable shelf unit 10, an automatic transport trolley 20, and a control system , communication system, ground navigation system 30 and other components. In this embodiment, the automatic transfer trolley 20 is automatically connected and disconnected from the transfer rack unit 10 by a jacking method as an example.

[0085] Several transportable shelf units 10 and several automatic transfer trolleys 20 form the hardware facilities of the transportable shelf storage system. For items with a high degree of overlap between orders, a passageway for the automatic transfer trolley 20 is reserved between the shelves to obtain faster entry and exit efficiency; for items with a low degree of overlap between orders, the There is no ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com