Preparation method of sulfur dioxide industrial raw material gas

A sulfur dioxide and raw gas technology, applied in chemical instruments and methods, inorganic chemistry, sulfur compounds, etc., can solve the problems of low concentration of raw gas, difficulty in market competition, loss of economic value, etc., and achieve high decomposition reaction efficiency and low sulfur loss , considerable economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

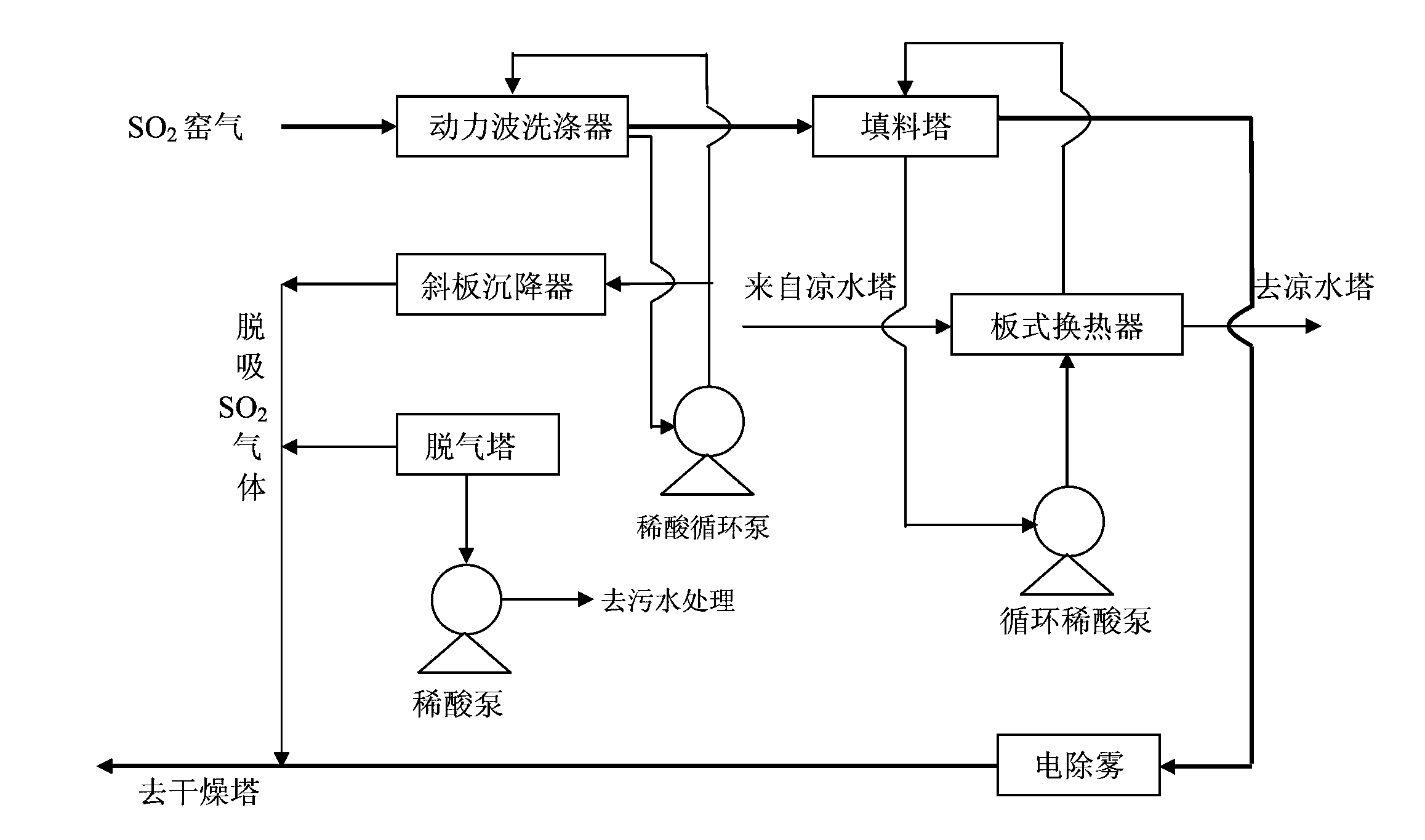

Image

Examples

Embodiment 1

[0025] A kind of preparation method of sulfur dioxide industrial raw material gas, carry out according to the following steps:

[0026] 1. Raw material equipment: 85% gypsum, 6% coke, 3% yellow sand, 4% shale, and 2% iron powder are used as raw materials by mass percentage, and the gypsum is CaSO 4 Gypsum and coke with content ≥ 85% are coke with fixed carbon ≥ 75%, gypsum particle size is 0.08㎜ sieve residue is 18%, coke particle size is 0.2㎜ sieve residue < 20%; the ratio of each material is measured by belt scale To achieve this, the addition of raw material is added with a metering screw, so that the feeding is uniform and smooth, no material breakage occurs, the metering is accurate, and the adjustment is free;

[0027] 2. Calcination reaction in the rotary kiln: Add the raw material prepared above into the rotary kiln for calcination, and control the kiln speed of the rotary kiln at 1.5 rpm; The gun enters to ensure that the coal powder enters the kiln evenly and burns....

Embodiment 2

[0049] A kind of preparation method of sulfur dioxide industrial raw material gas, carry out according to the following steps:

[0050] 1. Raw material equipment: 83% gypsum, 8% coke, 5% yellow sand, 2% shale, and 2% iron powder are used as raw materials in mass percentages. For ≥75% coke, the gypsum particle size is 0.08㎜ and the sieve residue is 15%, and the coke particle size is 0.2㎜ and the sieve residue is <20%. To achieve uniform and smooth feeding, no material breakage, accurate measurement, and free adjustment;

[0051] 2. Calcination reaction in the rotary kiln: add the raw material prepared above into the rotary kiln for calcination, control the kiln speed of the rotary kiln at 2.5 rpm; The gun enters to ensure that the coal powder enters the kiln evenly and burns. The primary air volume accounts for 20% of the total air volume. The secondary air comes from the hot air discharged from the kiln air beam grate cooler after cooling the clinker, and the secondary air vo...

Embodiment 3

[0057] A kind of preparation method of sulfur dioxide industrial raw material gas, carry out according to the following steps:

[0058] 1. Raw materials: 88% gypsum, 4% coke, 3% yellow sand, 4% shale, and 1% iron powder are used as raw materials by mass percentage, and the gypsum is CaSO 4 Gypsum and coke with a content of ≥85% are cokes with a fixed carbon content of ≥75%. The sieve residue of gypsum with a particle size of 0.08mm is 20%, and the sieve residue of coke with a particle size of 0.2mm is less than 20%. To achieve this, the addition of raw material is added with a metering screw, so that the feeding is uniform and smooth, no material breakage occurs, the metering is accurate, and the adjustment is free;

[0059] 2. Calcination reaction in the rotary kiln: add the raw material prepared above into the rotary kiln for calcination, control the kiln speed of the rotary kiln at 2.0 rpm; The gun enters to ensure that the coal powder enters the kiln evenly and burns. The...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap