Concrete reinforced column for steel framework of hybrid FRP (Fiber Reinforced Plastic) pipe

A technology of concrete and composite columns, applied in the direction of columns, pier columns, pillars, etc., can solve the problems of FRP pipe damage and unsatisfactory ductility, and achieve the effect of increasing utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

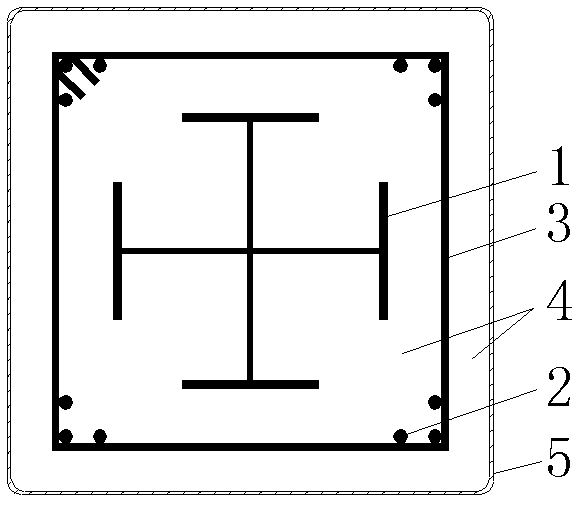

[0036] now attached figure 1 Further explain the present invention: first determine the size and model of steel frame 1 and hoist it in place, bind longitudinal steel bars 2 and stirrup bars 3 on the periphery of steel frame 1, formwork is supported on the outside after the reinforcement is arranged, and concrete is poured in the formwork 4. After curing until the strength of the concrete 4 meets the requirements for form removal, remove the formwork, and finally paste hybrid FRP materials on the outside of the column to form a hybrid FRP pipe 5 .

[0037] The column in this embodiment adopts a square column with a side length of 700mm, and the length of the column is 3m.

[0038] The type of steel used in steel frame 1 is Q235, the total length of the vertical and transverse webs (the distance between the flange ends) of the steel frame 1 section is 378mm, and the width is 7mm; the steel frame 1 is connected with the web The length of the four outer flange plates is 200mm, a...

Embodiment 2

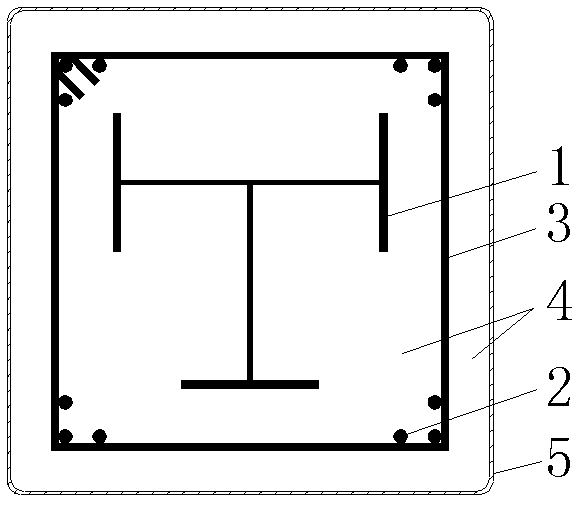

[0044] This embodiment adopts the same implementation steps as in Embodiment 1, but adopts different cross-sectional dimensions, such as Figure 7 Shown:

[0045] The type of steel used in steel frame 1 is Q235, the length of the web between the ends of the two flanges of the steel frame 1 section is 460 mm, and the width is 12 mm; the lengths of the two flange plates connected to the web in steel frame 1 are both 158 mm. The width is 20mm.

[0046] Four HRB335 longitudinal steel bars 2 with a diameter of 20mm are used on the column section, and one is arranged at each of the four corners of the column section. The clear distance between the longitudinal steel bars 2 and the outer surface of the concrete column is 35mm.

[0047] The stirrup 3 adopts HPB235 grade steel bars with a diameter of 10mm, and the spacing along the longitudinal direction is 150mm.

[0048] The grade of concrete 4 is C30.

[0049] The outer surface of the concrete column is pasted with two layers of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com