FRP pipe-core steel reinforced sea sand concrete column

A technology of concrete columns and sea sand, applied in the direction of columns, pier columns, pillars, etc., can solve the problems of insufficient strength and bearing capacity, low stiffness and bearing capacity, collapse of building structures, etc. Utilization rate, corrosion prevention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

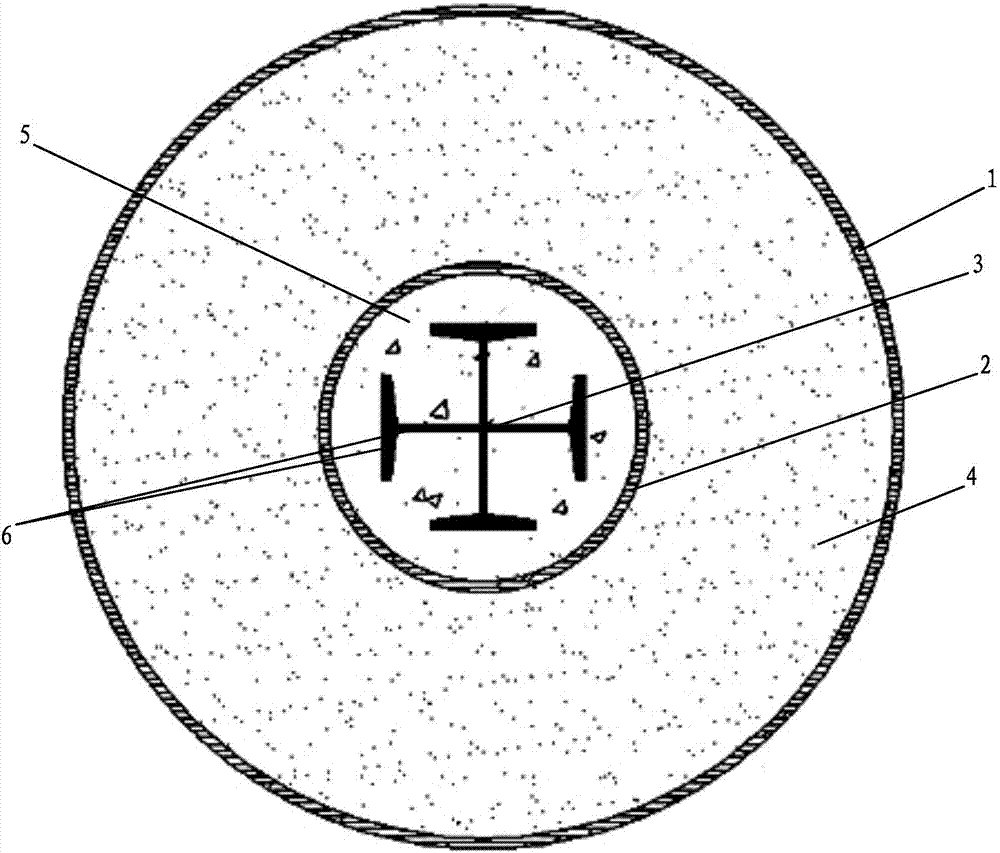

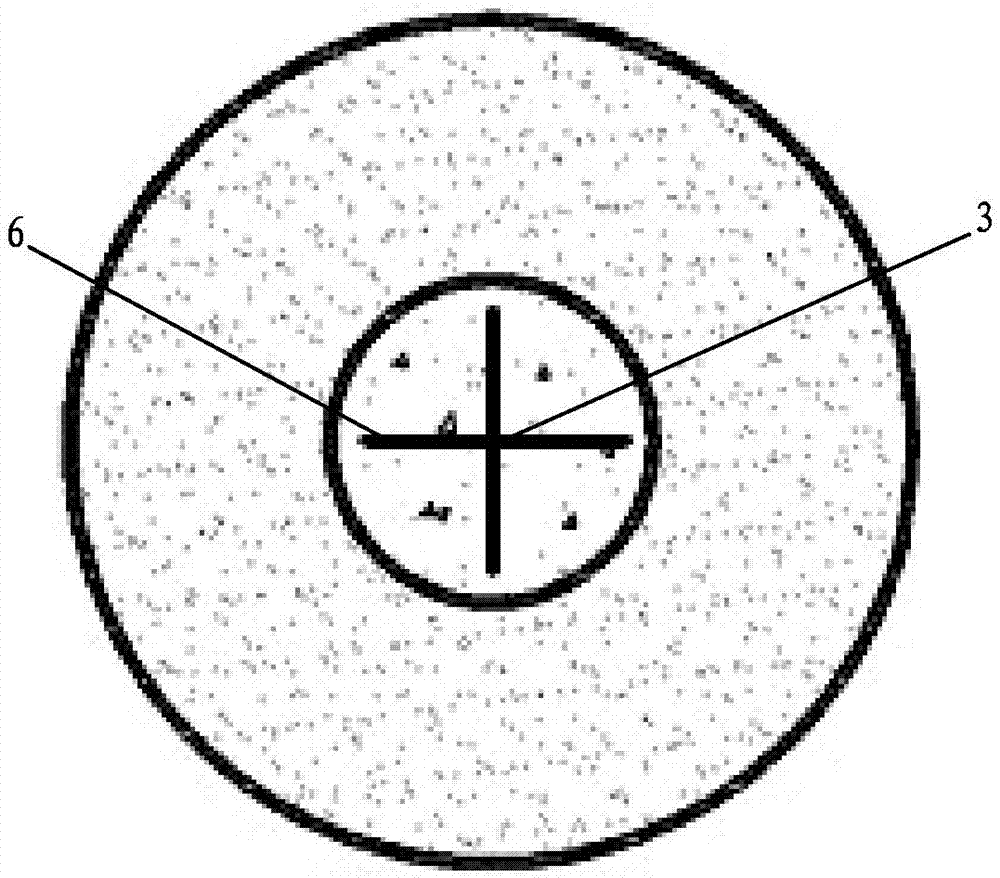

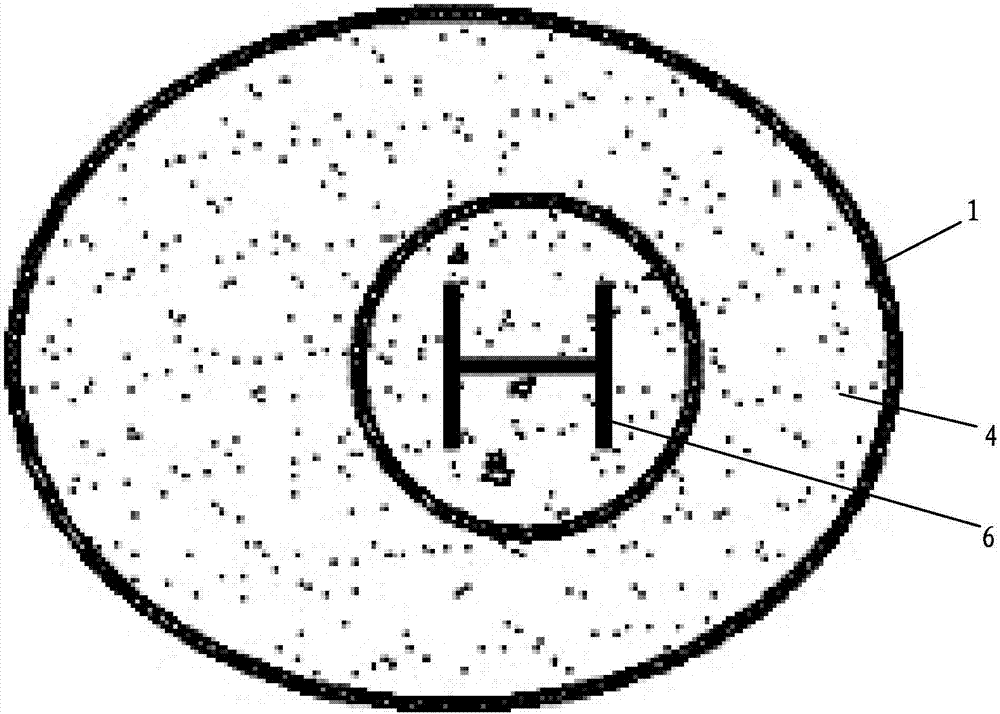

[0027] refer to figure 1 , this embodiment relates to an FRP pipe-core steel frame sea-sand concrete column, including an outer FRP pipe 1, an inner FRP pipe 2 and a steel skeleton 3 disposed in the outer FRP pipe 1, and two sets of inner FRP pipes It is arranged in the outer FRP pipe 1, and the sea sand concrete 4 is filled between the inner FRP pipe 2 and the outer FRP pipe 1 to fix the inner FRP pipe 2 and the outer FRP pipe 1 together; The steel frame 3 is arranged in the inner layer FRP pipe 2, and concrete 5 is filled between the inner layer FRP pipe 2 and the steel frame 3 to fix the inner layer FRP pipe 2 and the steel frame 3 together; the steel frame 3 Extend and distribute along the axial direction of the inner layer FRP pipe 2 .

[0028] The present invention adopts a double FRP pipe structure, and fills sea sand concrete 4 between inner and outer FRP pipes 1 to form a double FRP pipe concrete column structure. Due to the corrosion resistance of the FRP pipe, und...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com