Test evaluation method of LED (light emitting diode) packaging adhesive

A technology of LED packaging and evaluation method, applied in the field of testing to achieve cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

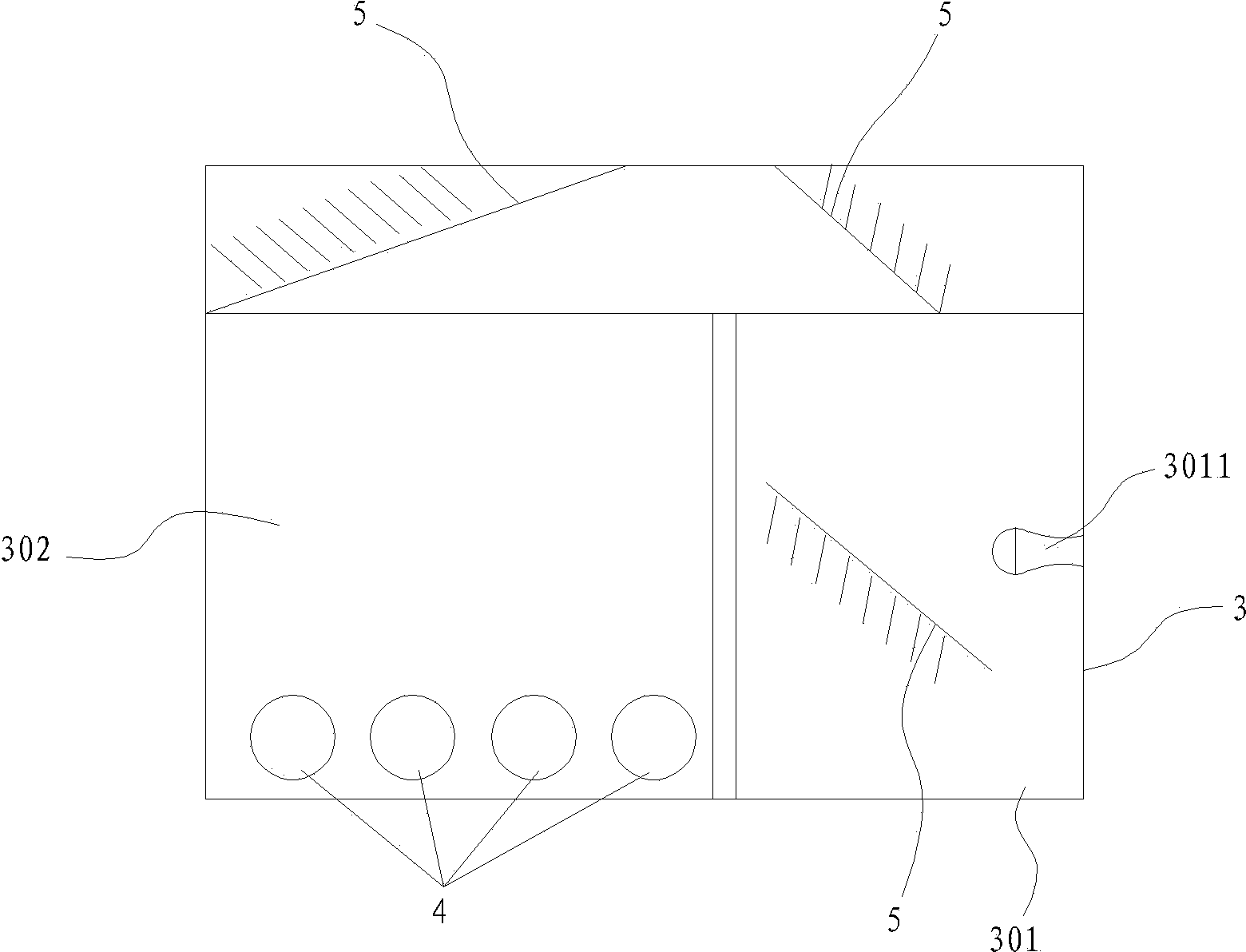

[0021] The test and evaluation method of LED packaging glue of the present invention specifically comprises the steps:

[0022] Step S1: dispensing and curing to form an LED encapsulation film, and preparing an LED encapsulation film to be tested. The curing conditions of the LED encapsulation film here are exactly the same as the curing conditions of the LED product in the encapsulation process, so that the test of the LED encapsulation film is equivalent to the performance of the LED encapsulation film under this encapsulation process, so that the test results The performance data of LED encapsulant has high reference significance.

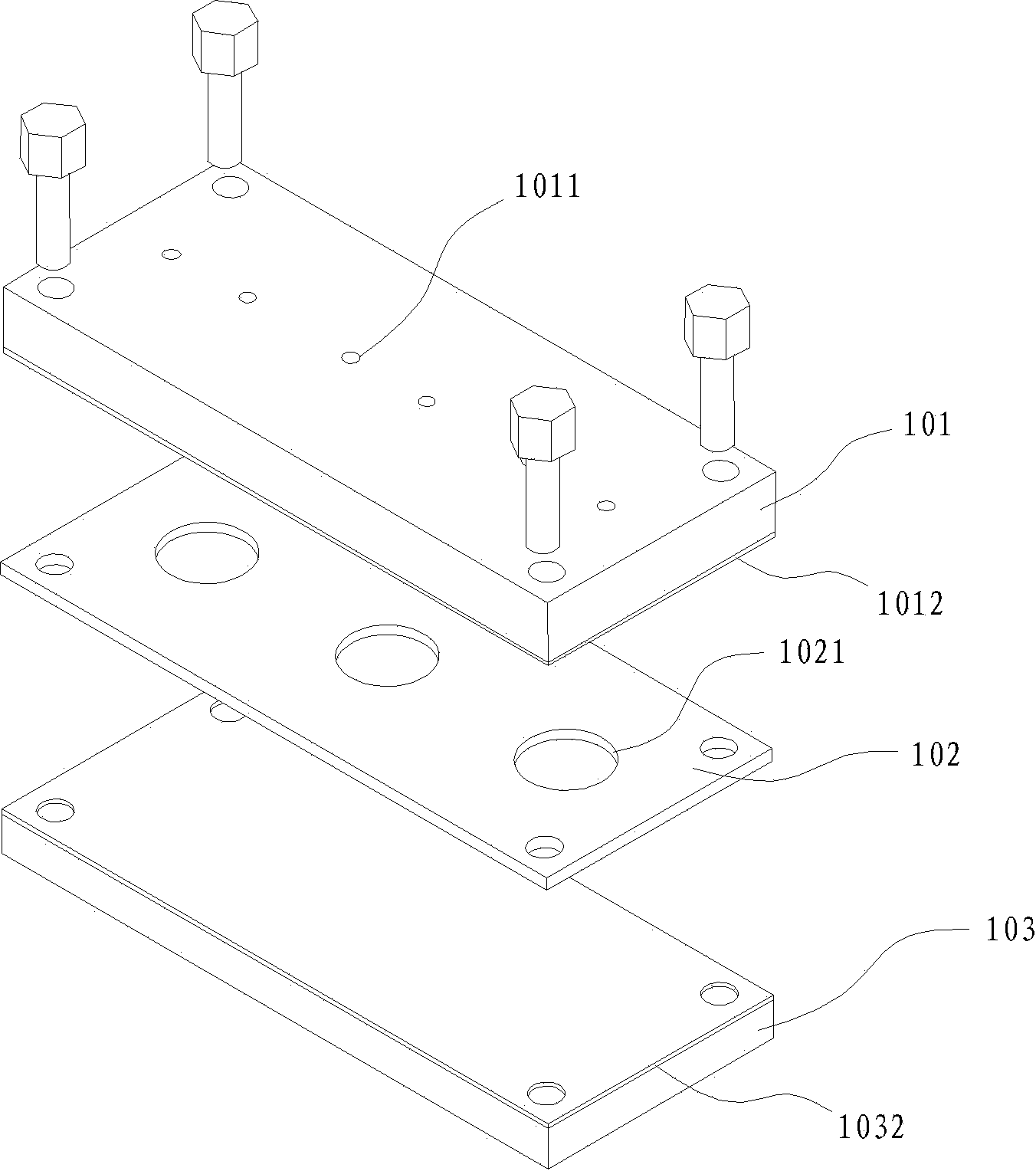

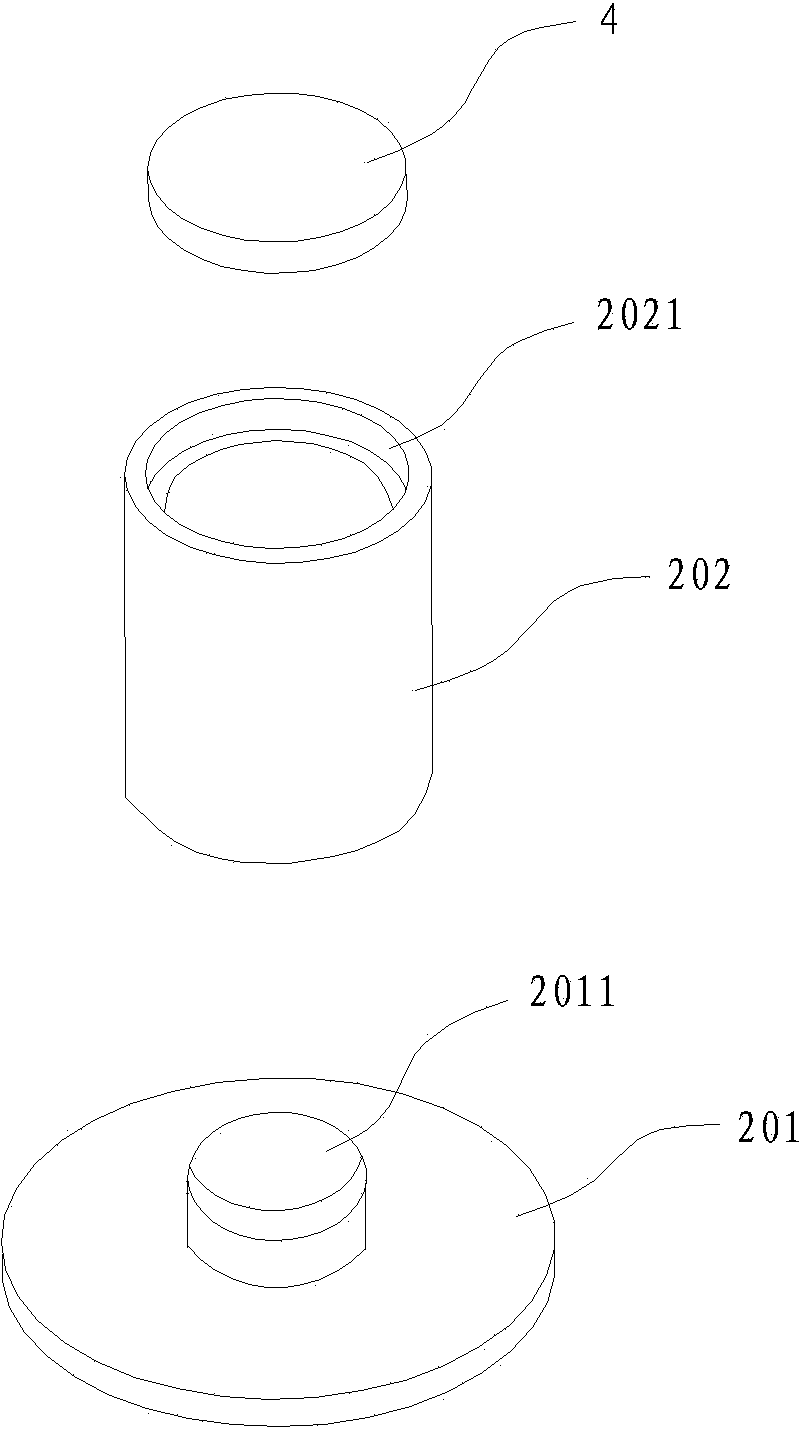

[0023] Among them, in step S1, the LED packaging film to be tested is formed by dispensing and curing, which can be made by conventional methods such as dispensing equipment, spraying equipment, mechanical cutting, et...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com