LED (light-emitting diode) backlight drive circuit, liquid crystal display device and drive method

A technology of backlight drive circuit and LED light bar, which is applied in the direction of electrical components, static indicators, instruments, etc., can solve the problems of poor adjustment accuracy, achieve the effects of improving efficiency, wide adjustment range, and improving comparison accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

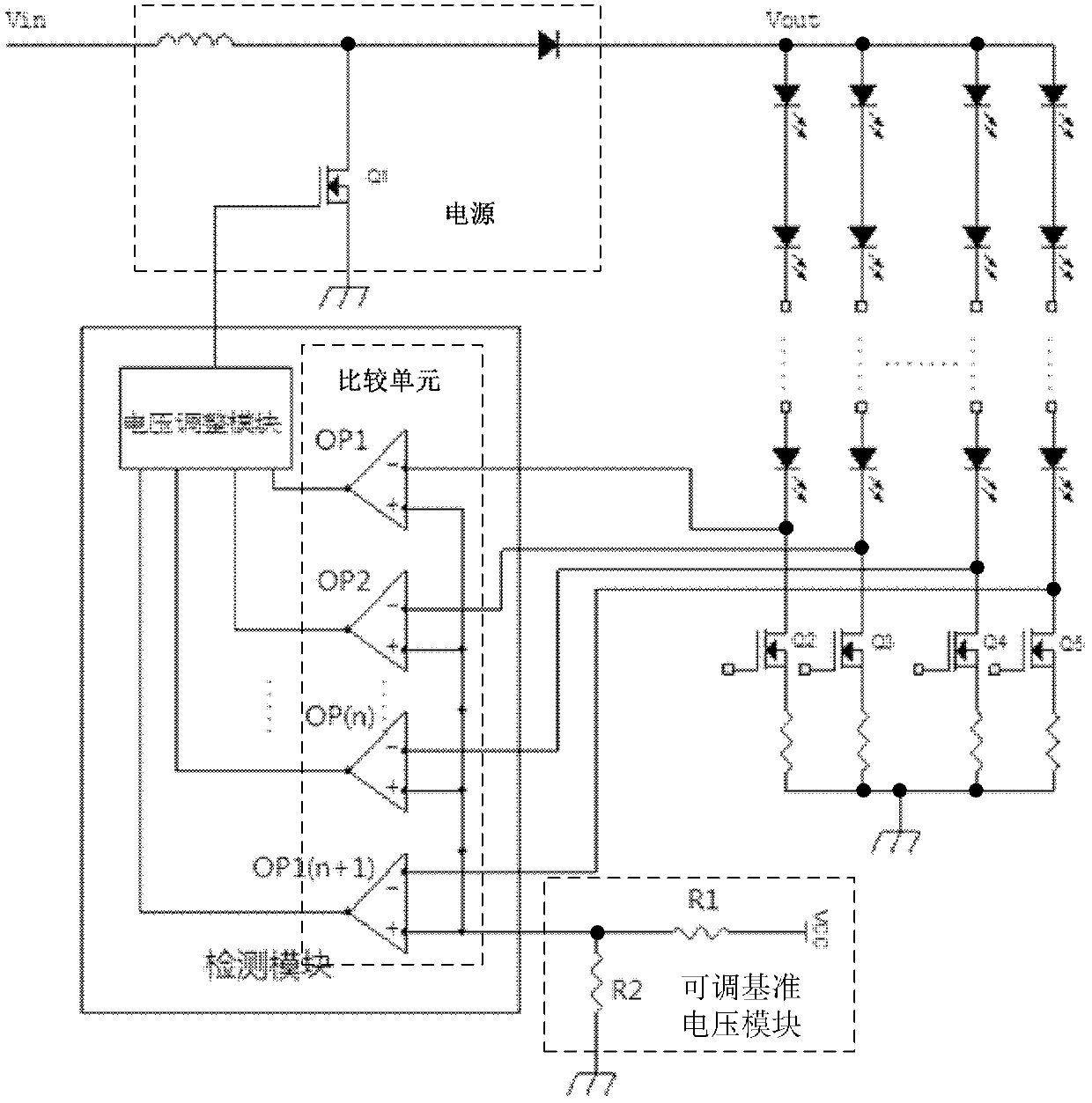

[0026] Such as figure 2 As shown, the comparison unit includes a plurality of comparators OP1~OP(n+1), the comparison terminal of each comparator is correspondingly coupled to the output terminal of an LED light bar, and its reference terminals are connected to each other; the adjustable reference voltage module includes a series One end of the first resistor R1 is connected to a fixed reference voltage, and the other end is connected to the second resistor R2; one end of the second resistor R2 is connected to the first resistor R1, and the other end is grounded; each comparison The reference end of the resistor is coupled between the first resistor R1 and the second resistor R2. The comparison unit is divided into multiple comparators, and each comparator only collects the voltage of one LED light bar, the charge burden is small, the heat generation is reduced, and the heat of the comparison unit is distributed to multiple separate comparators, which can improve the heat dis...

Embodiment 2

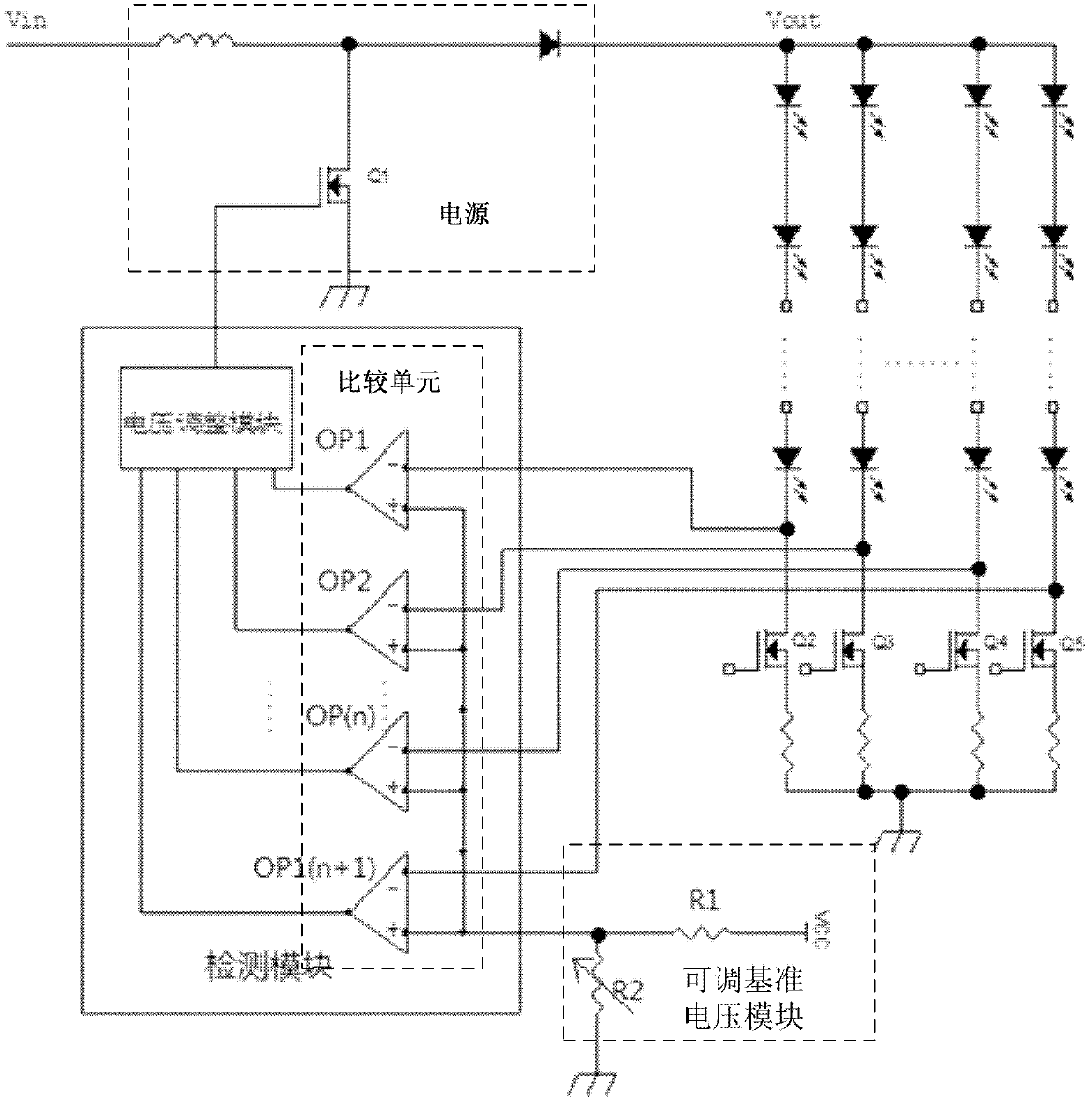

[0030] Such as image 3 As shown, the comparison unit includes a plurality of comparators OP1~OP(n+1), the comparison terminal of each comparator is correspondingly coupled to the output terminal of an LED light bar, and its reference terminals are connected to each other; the adjustable reference voltage module includes a series The first resistor R1 and the second resistor R2, one end of the first resistor R1 is connected to a fixed reference voltage, and the other end is connected to the second resistor R2; the second resistor R2 is an adjustable resistor, one end of which is connected to the first resistor R1, and the other end is connected to the second resistor R2 One terminal is grounded; the reference terminal of each comparator is coupled between the first resistor R1 and the second resistor R2. The comparison unit is divided into multiple comparators, and each comparator only collects the voltage of one LED light bar, the charge burden is small, the heat generation i...

Embodiment 3

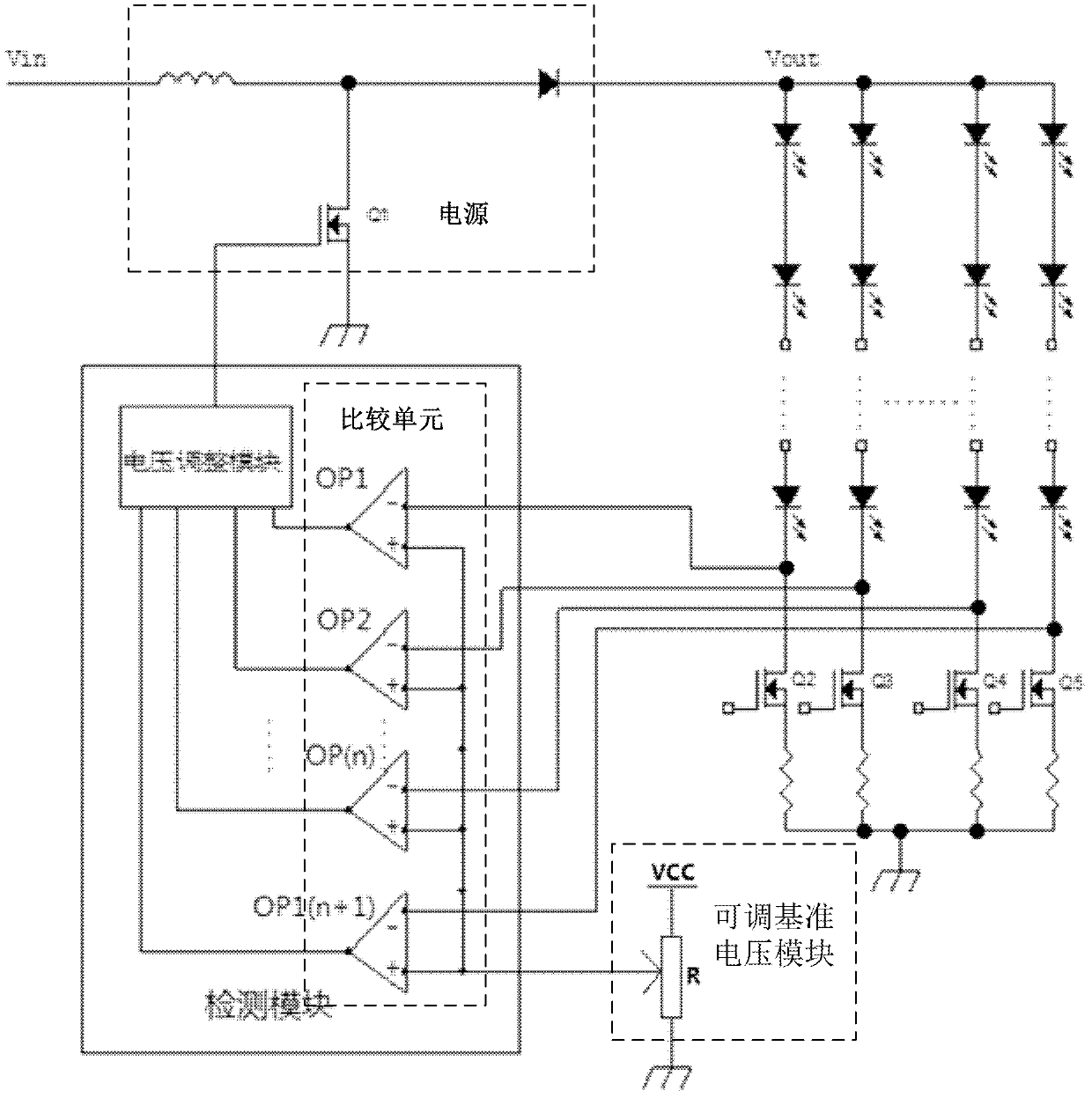

[0034] Such as Figure 4 As shown, the comparison unit includes a plurality of comparators OP1~OP(n+1), the comparison terminal of each comparator is correspondingly coupled to the output terminal of an LED light bar, and its reference terminals are connected to each other; the adjustable reference voltage module includes an adjustable An adjustable resistor R, one end of the adjustable resistor R is connected to a fixed reference voltage, and the other end is grounded; the reference end of each comparator is coupled to the output end of the adjustable resistor R. The comparison unit is divided into multiple comparators, and each comparator only collects the voltage of one LED light bar, the charge burden is small, the heat generation is reduced, and the heat of the comparison unit is distributed to multiple separate comparators, which can improve the heat dissipation efficiency. It is beneficial to detect the heat dissipation of the module.

[0035] The detection module also...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com