Porcelain insulator for power capacitor

A technology of ceramic insulators and power capacitors, which is applied in the direction of insulators, lead-in/through-type insulators, circuits, etc., can solve the problems of cumbersome processing and installation operations, affecting sealing performance, etc., to achieve reasonable and compact structure, ensure sealing performance, prevent The effect of slipping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

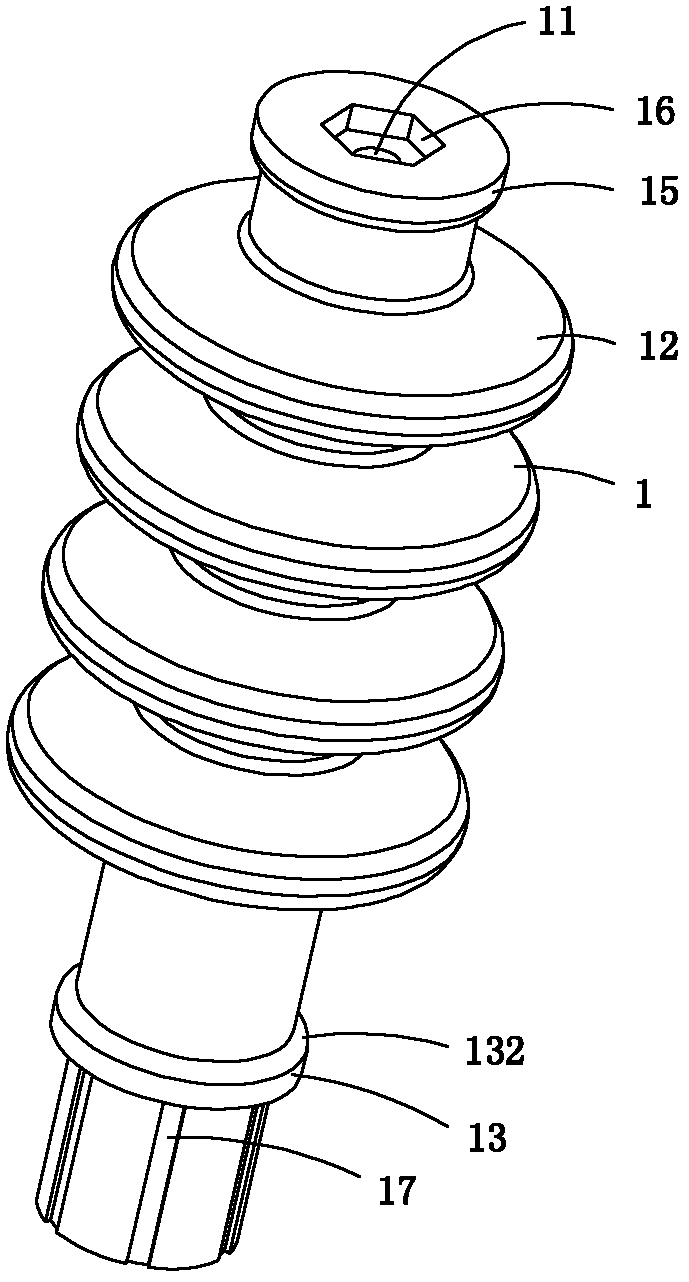

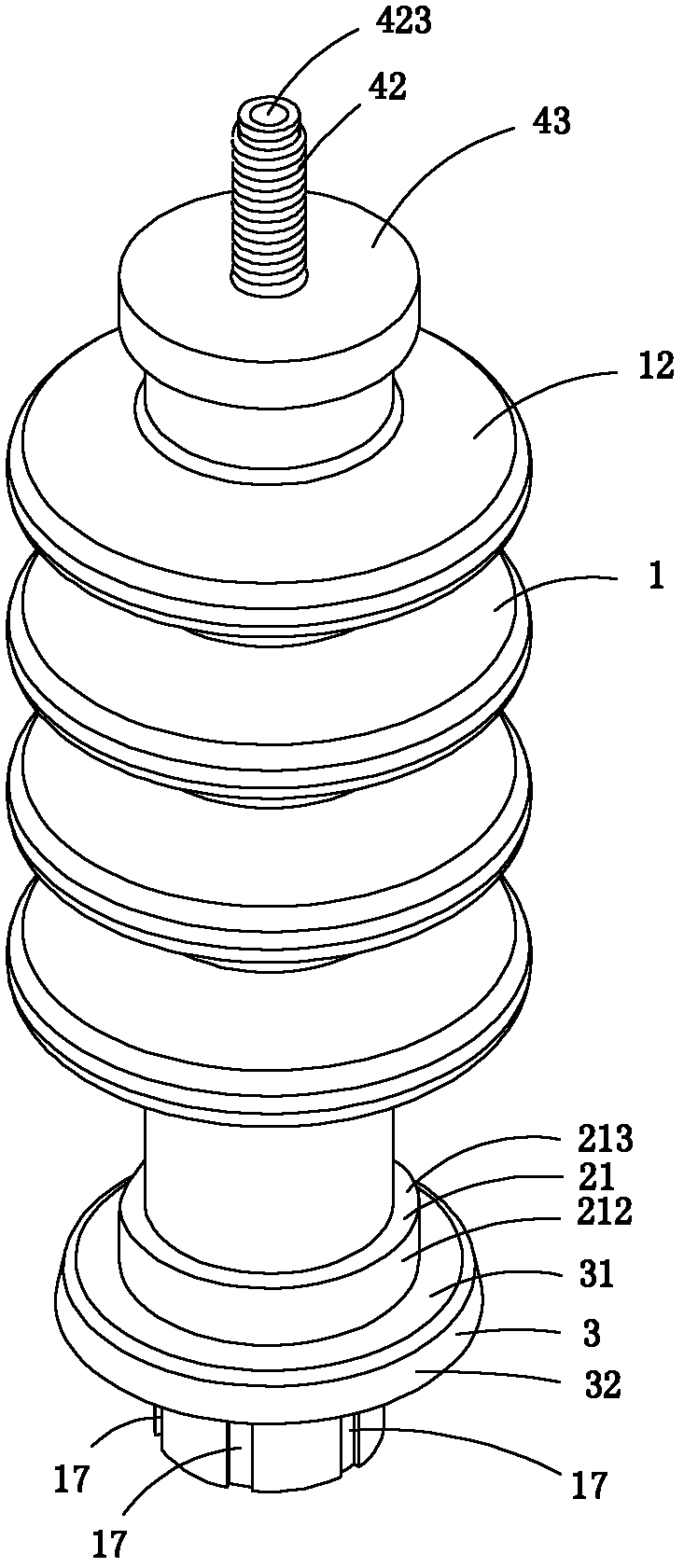

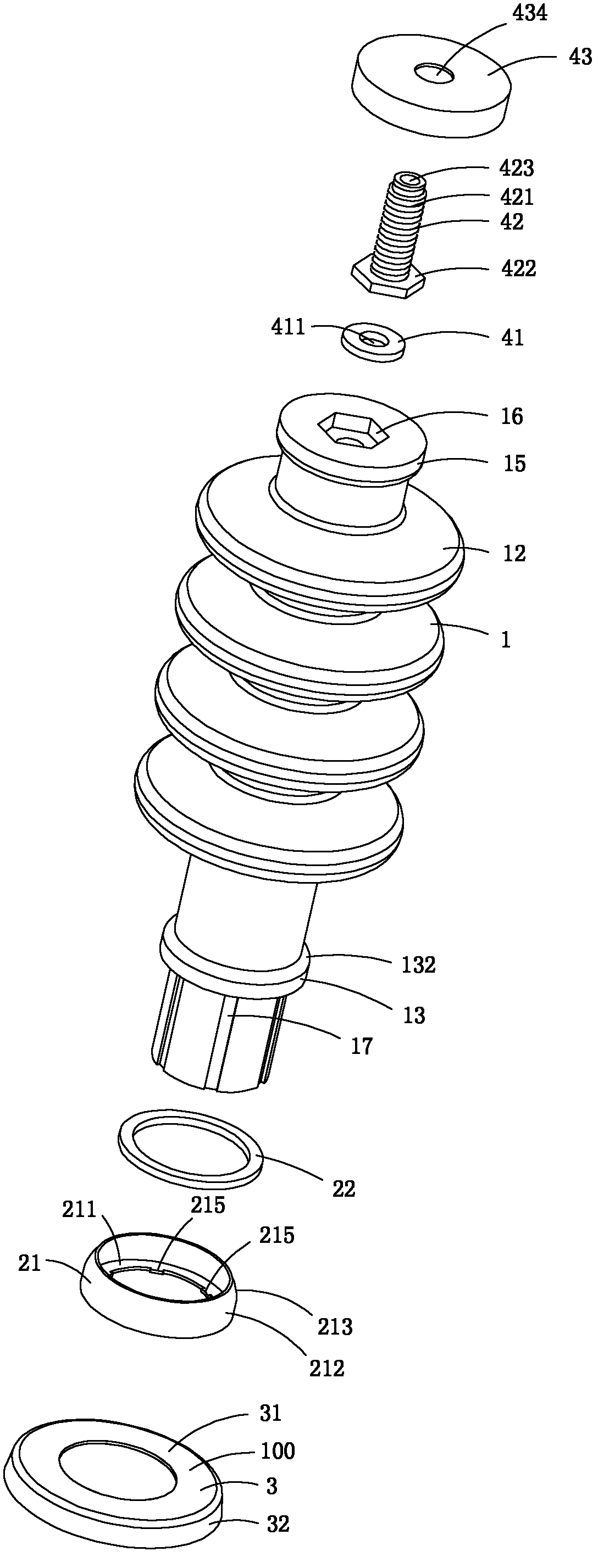

[0020] figure 1 It is a schematic diagram of a three-dimensional structure of the present invention, showing a specific embodiment of the present invention.

[0021] This embodiment is a ceramic insulator for power capacitors, see figure 1 As shown, the insulator 1 is provided with a through hole 11 along its central axis, a plurality of sheds 12 are provided on the outer wall of the middle part, and an annular positioning boss 13 protruding radially is provided on the outer wall of the lower part. The outer wall is provided with a radially protruding annular rolling fastening part 15, a groove 16 is provided at the center of the top end wall of the upper part of the insulator 1, and the through hole 11 of the ceramic insulator 1 is located at the center of the groove 16. place.

[0022] In this embodiment, the outer wall of the lower part of the insulator 1 is further provided with a plurality of positioning grooves 17 extending along the axial direction, and each positioni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com