Smart matrix battery charging-discharging managing system and managing method

A charge and discharge management and battery system technology, applied in the field of smart matrix battery charge and discharge management system and management, can solve the problem that the full state of the series unit cannot be guaranteed, the working efficiency and service life of the battery pack are affected, and the current control of the series unit cannot be achieved. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The smart matrix battery charging and discharging management system and management method of the present invention will be described in detail below with reference to the drawings and embodiments.

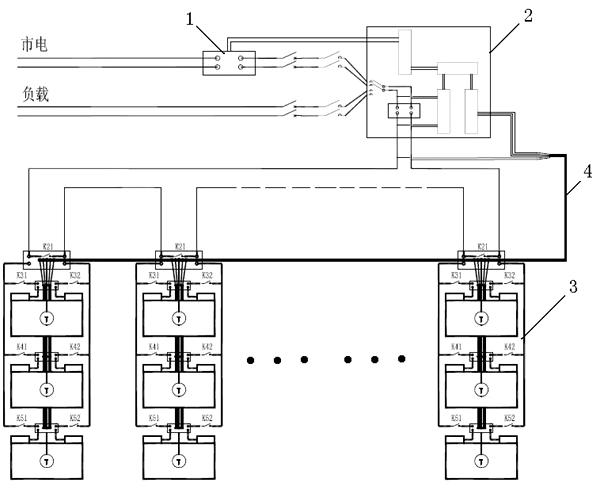

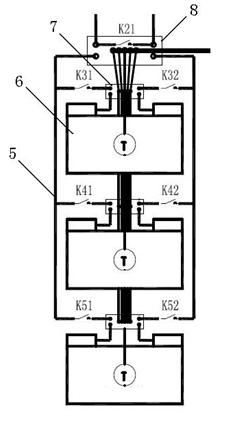

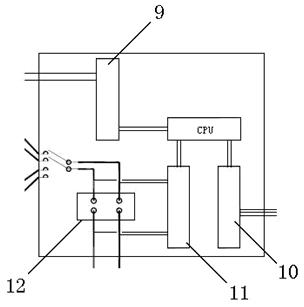

[0036] Such as Figure 1 to Figure 3 As shown, in the intelligent matrix battery charge and discharge management system of the present invention, a plurality of series units 3 in the system are connected in series to the power supply and the load through the general controller 2 . The power supply connected with the general controller 2 is a variable output voltage power supply 1 . The overall controller 2 is provided with a measuring circuit 11 for measuring the total voltage and current of the entire battery system; a voltage regulating circuit 9 connected to a variable output voltage power supply and a control circuit 10 for controlling each series unit; providing short circuit, overload, A protection circuit 12 with protection functions such as reverse polarity, undervo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com