Assembling type three-freedom-degree flotation tank bracket

A degree of freedom, flotation cell technology, applied in the field of brackets, can solve the problems of increasing the installation and adjustment time of brackets, being unable to support flotation cells, and occupying a large space, etc., achieving less adjustment times, convenient adjustment, and convenient installation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] A specific embodiment of the present invention will be described below in conjunction with the accompanying drawings.

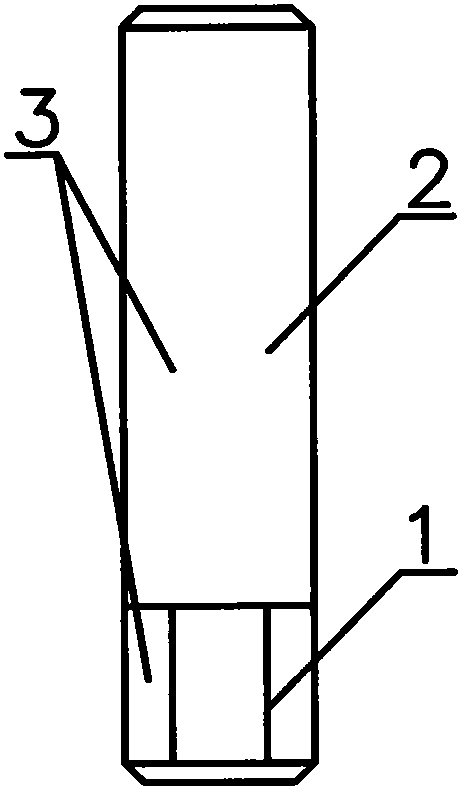

[0028] figure 1 It is the front view of the pole of the bracket of the present invention.

[0029] Such as figure 1 As shown, the vertical rod 3 is composed of a positioning end 1 and a polished rod end 2 . The positioning end 1 is a regular polygonal prism.

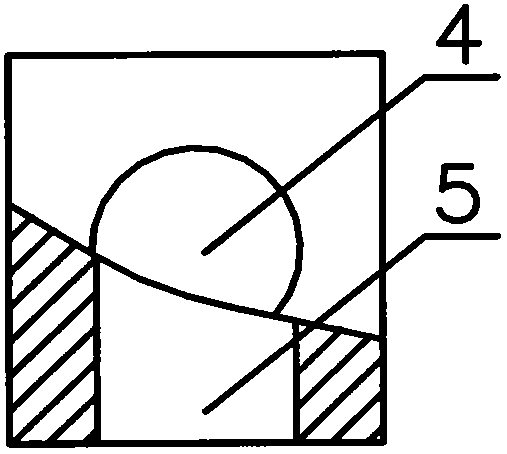

[0030] figure 2 It is the front view of the height adjustment sleeve of the bracket of the present invention.

[0031] Such as figure 2 As shown, the height adjustment sleeve 5 is a hollow sleeve, and a threaded through hole 4 is opened on the side. When installing, the sleeve 5 can be positioned by screwing in the fastening screw from the hole.

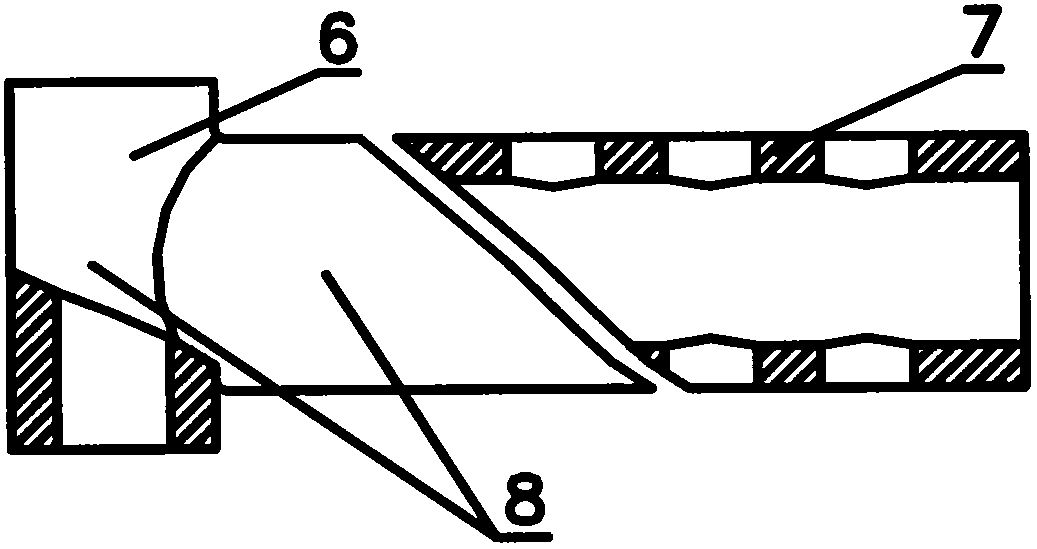

[0032] image 3 It is the front view of the rotating sleeve part of the bracket of the present invention.

[0033] Such as image 3 As shown, the rotating sleeve part 8 is composed of a free sleeve 6 and a branch pipe 7, the free sleeve and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com