Welding technology practice training equipment and training methods

A technology of welding technology and training device, which is applied in the equipment field of welding technology practice training, can solve the problems that the welding training device cannot meet the training requirements well, the angle measurement of the welding training parts is troublesome, and the fixing of the training parts is not firm, etc., so as to prevent Effects of harmful light shed, simplification of welding training facilities, improvement of effectiveness and training efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

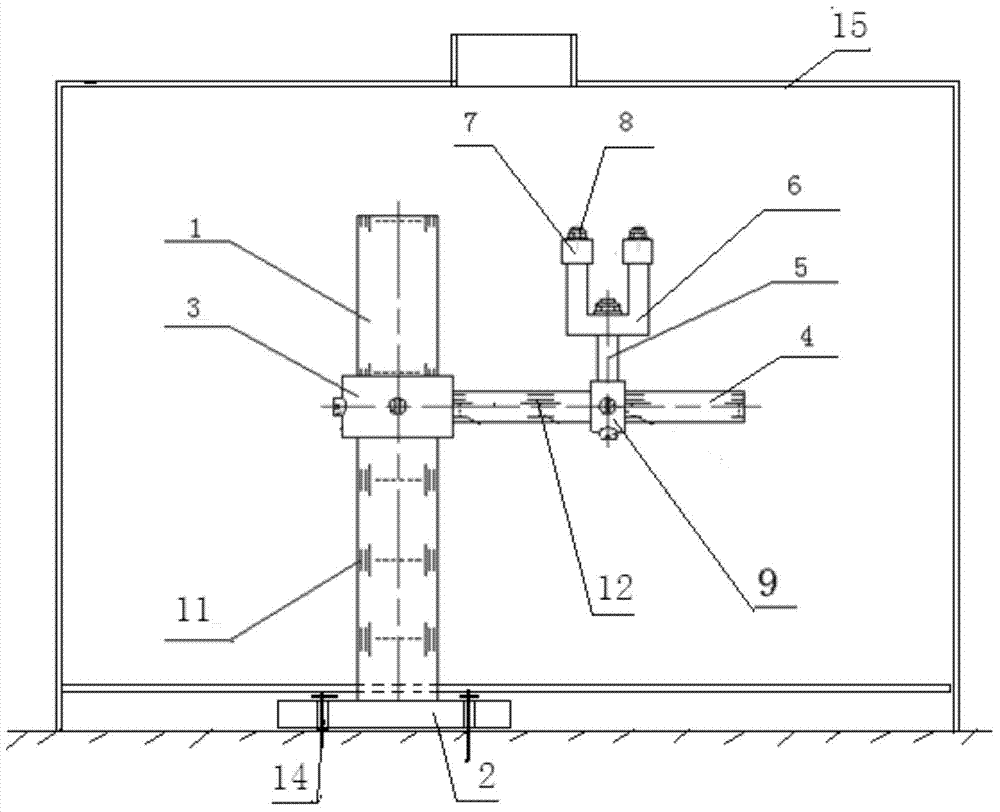

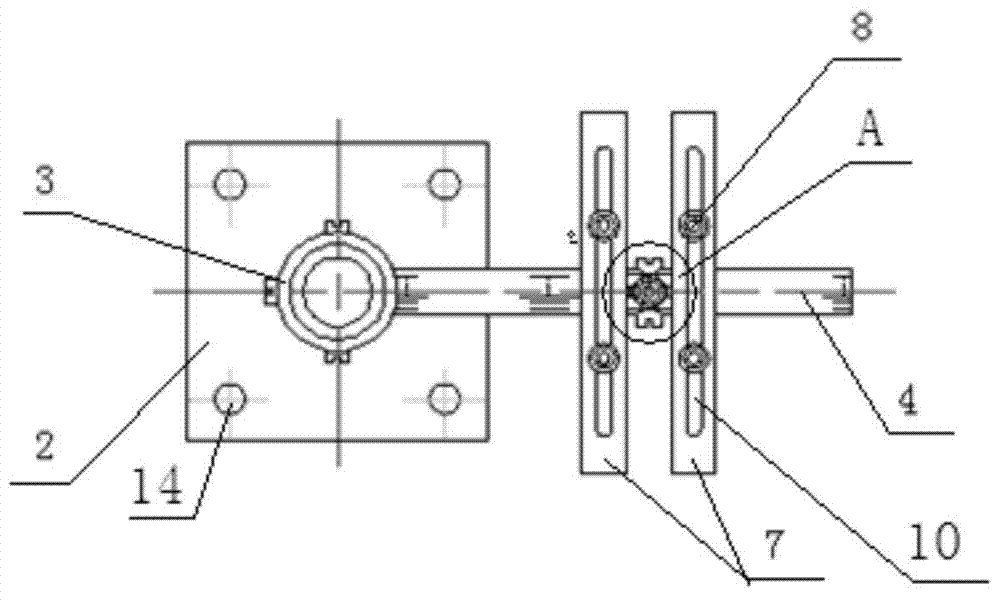

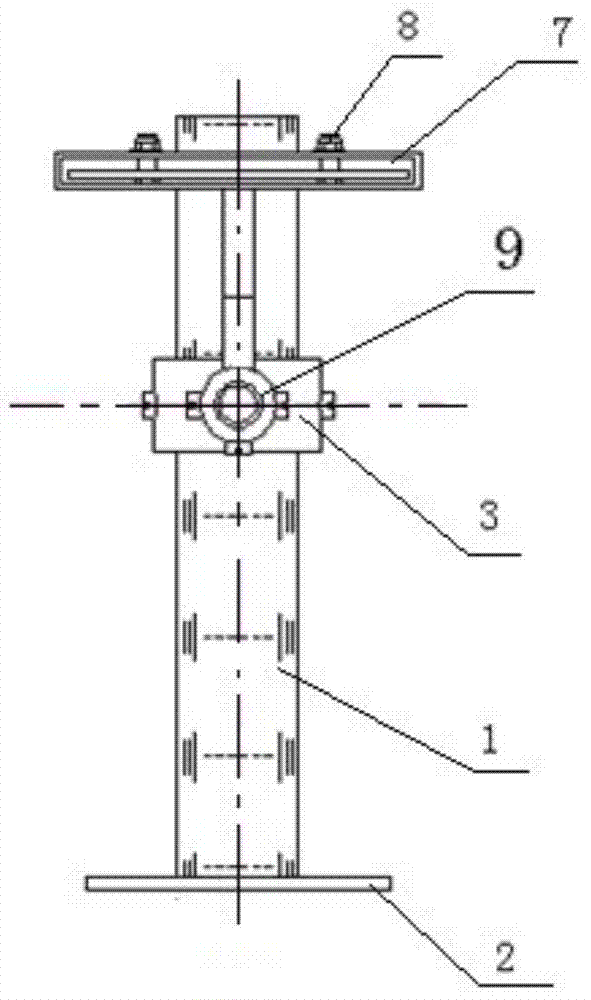

[0040] The present invention will be further described below in conjunction with the accompanying drawings.

[0041] Such as Figure 1-5 As shown, a kind of equipment for welding technology practice training, it is made up of protective device 15 and the universal training device arranged in protective device 15;

[0042] The structure of the protection device 15 is as Figure 5 As shown: it includes a space body capable of accommodating one person for welding demonstration operations. The space body is inlaid with transparent optical glass 17 for light filtering on the surrounding surfaces of a three-dimensional metal frame 16, and the top is covered with a flame-retardant top cover 18. The cover 18 is provided with an exhaust port 19, and one side of the space body is provided with an access door 20, which is also inlaid with transparent filtering optical glass; the bottom of the four corners of the metal frame 16 extends downward to a certain height, so that the four sides...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com