High-performance valve body of proportional servo valve and manufacturing method thereof

A technology of proportional servo valve and manufacturing method, applied in the direction of manufacturing tools, valve details, valve devices, etc., can solve problems such as short service life, difficult to remove burrs, stuck valve core, etc., to improve strength and cleanliness, and improve the manufacturing process Simple, reliable results that work together

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

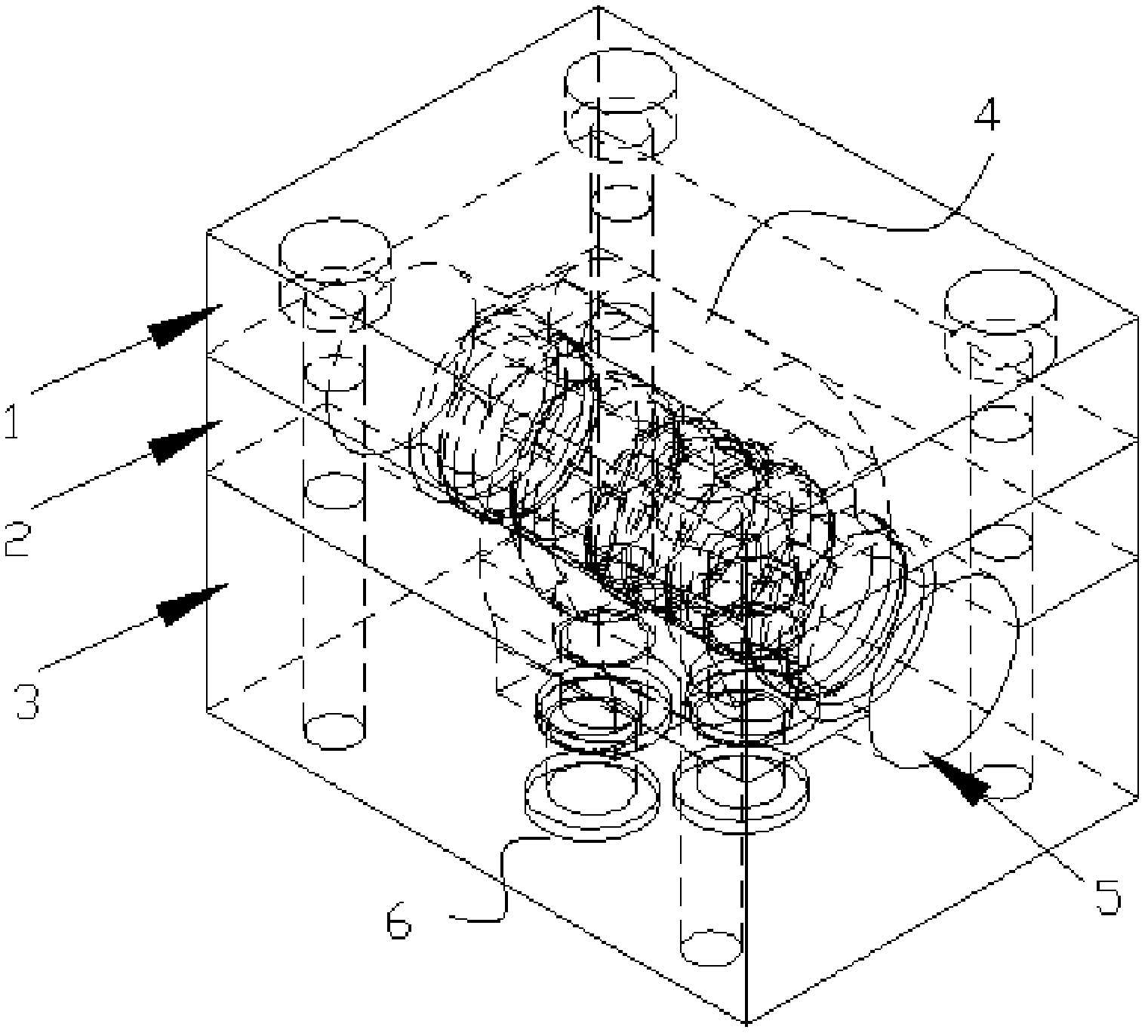

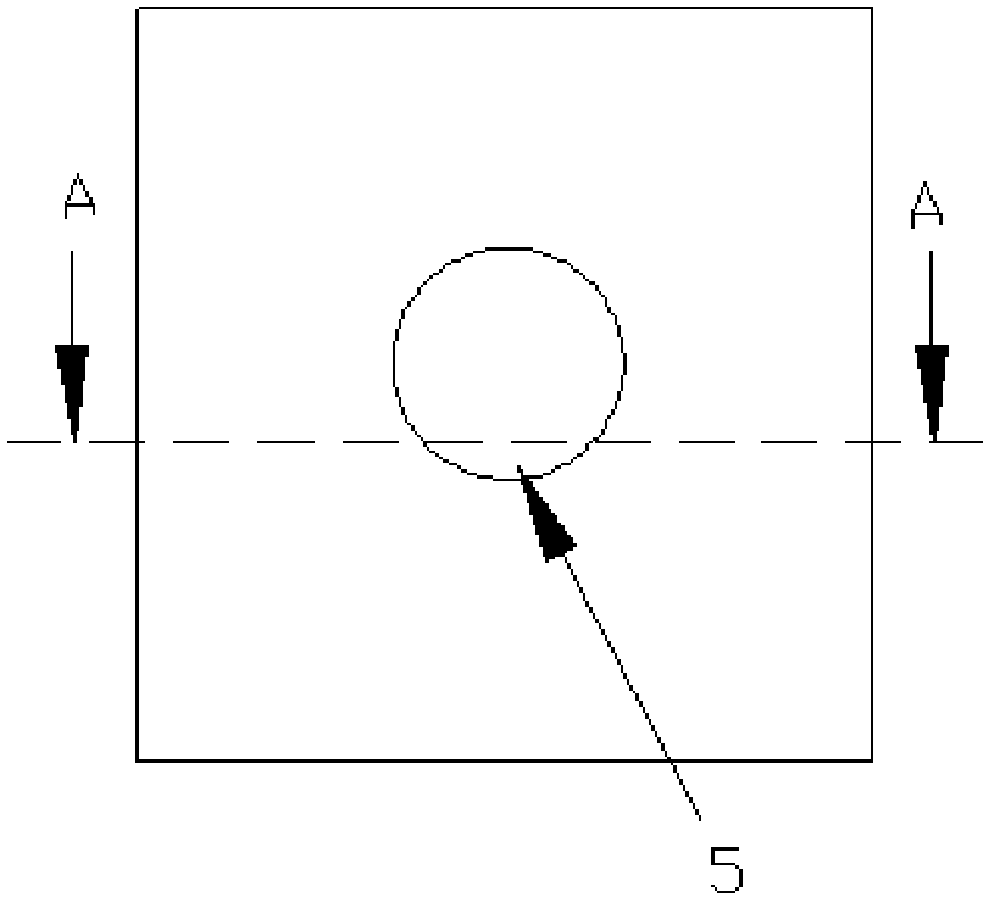

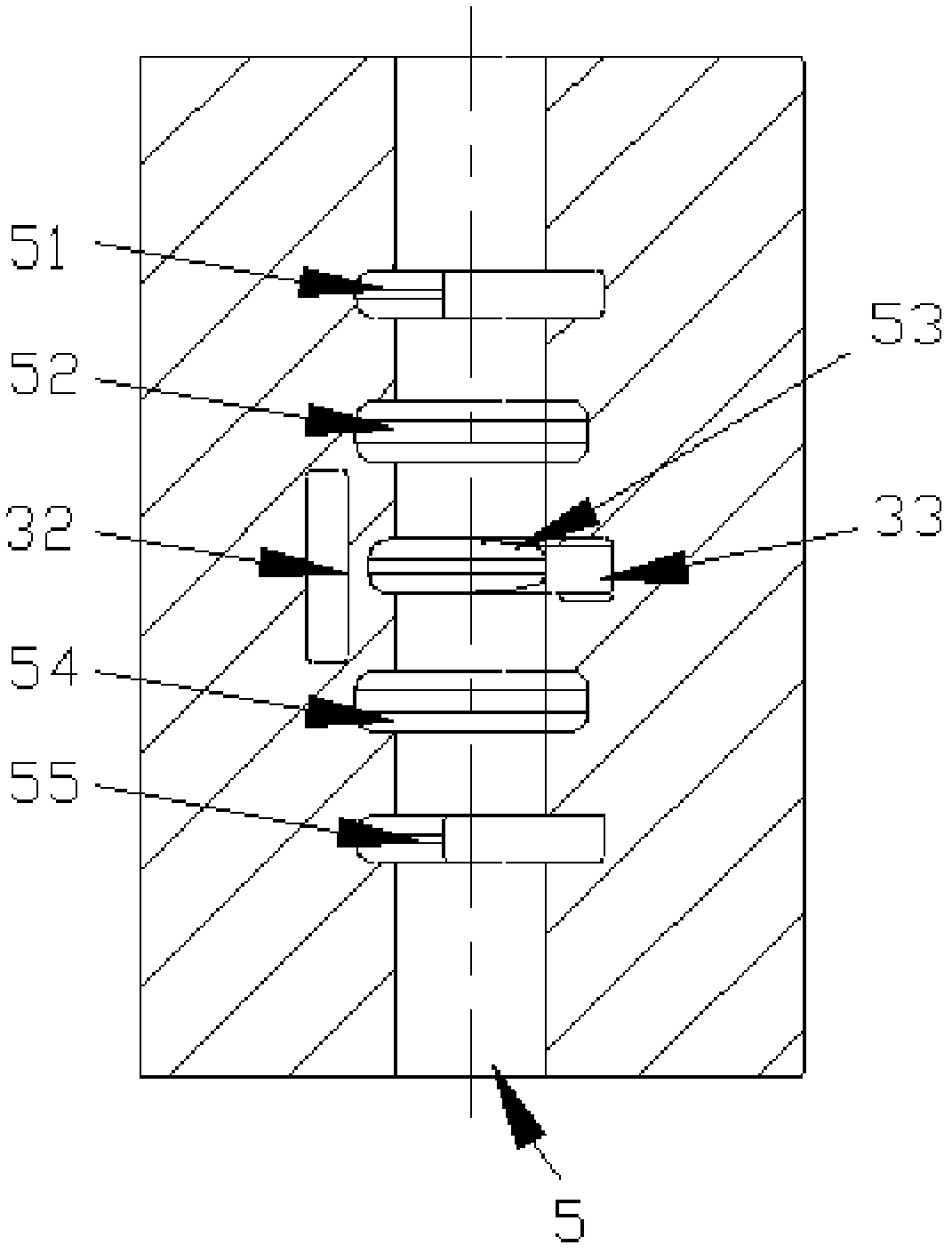

[0032] Such as figure 1 As shown, the high-performance proportional servo valve body of the present invention is composed of three cuboids: a first cuboid (1), a second cuboid (2) and a third cuboid (3), wherein the first cuboid (1) and the second cuboid A valve body dark cavity (4) is formed between (2), a valve body through hole (5) is formed between the second cuboid (2) and the third cuboid (3), and the valve body through hole (5) and the valve body The body dark cavity (4) is connected, and the third cuboid (3) is also provided with a plurality of working oil ports (6), and these working oil ports (6) are communicated with the through hole (5) of the valve body.

[0033] In order to manufacture the above-mentioned high-performance proportional servo valve body, the manufacturing method adopted by the present invention is as follows:

[0034] 1) Select a cylindrical blank, and use a precision forging machine to forge the cylindrical blank into a cuboid blank;

[0035] 2)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com