Cable twist-off preventing device of small-sized wind power generator

A technology for wind turbines and generators, applied in wind turbine components, wind turbines, wind power generation and other directions, can solve the problems of wind turbine failure, strong vibration of the generator, short circuit of the generator, etc., to solve the problem of arc burning, Low production cost and the effect of preventing from being twisted

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

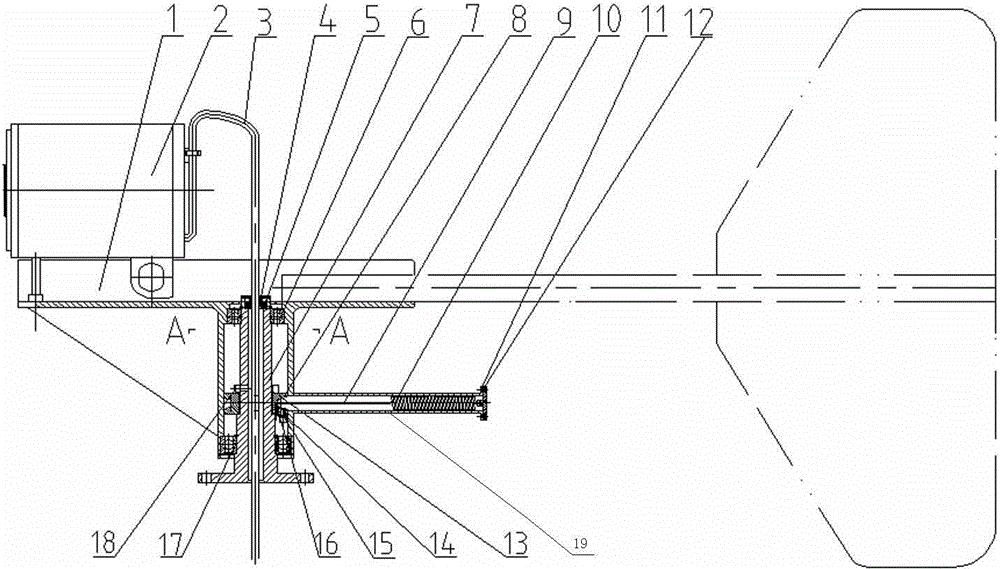

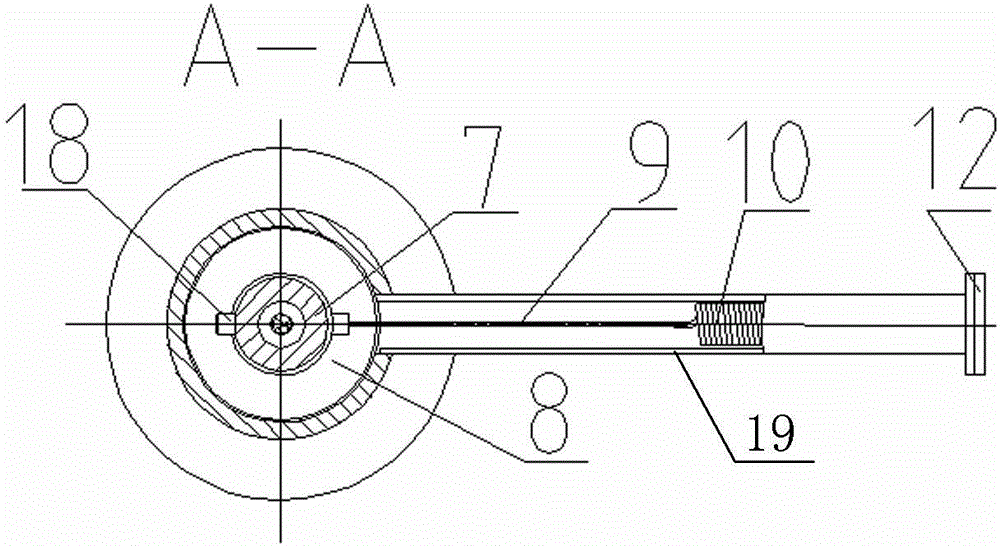

[0027] The present invention includes a column support 1, a wind power generator 2 installed on the column support, a support shaft 7 is installed in the column support 1 through two sealed bearings 5 and 6, and a cable 3 passes through the center hole of the support shaft 7 through a cable protection sleeve 4 , the reel assembly 8 is set empty on the support shaft 7, the reel assembly 8 is provided with a positioning block 13, and one end of the wire rope 9 is fastened to the reel assembly 7 through a flat washer 14, a spring washer 15 and a second screw 16. Below, the other end of steel wire rope 9 is hung on the left end of extension spring 10, and the right end of extension spring 10 is hung on end cover 12, and end cover 12 is fixed on column support 1 by screw 11, and support, 7 is equipped with positioning screw 18, When the positioning block 13 is in contact with the limit screw 18 on the support shaft 7, the winding wheel assembly 7 no longer rotates with the column ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com