Tubular oil-head recovery shaft

A technology of oil receiver and tubular type, which is applied in the field of accessories for general oil receiver of tubular turbines, which can solve problems such as twisting of threaded parts and polished rod parts, and failure of normal operation of unit oil receivers, so as to avoid twisting , the effect of increasing strength and stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

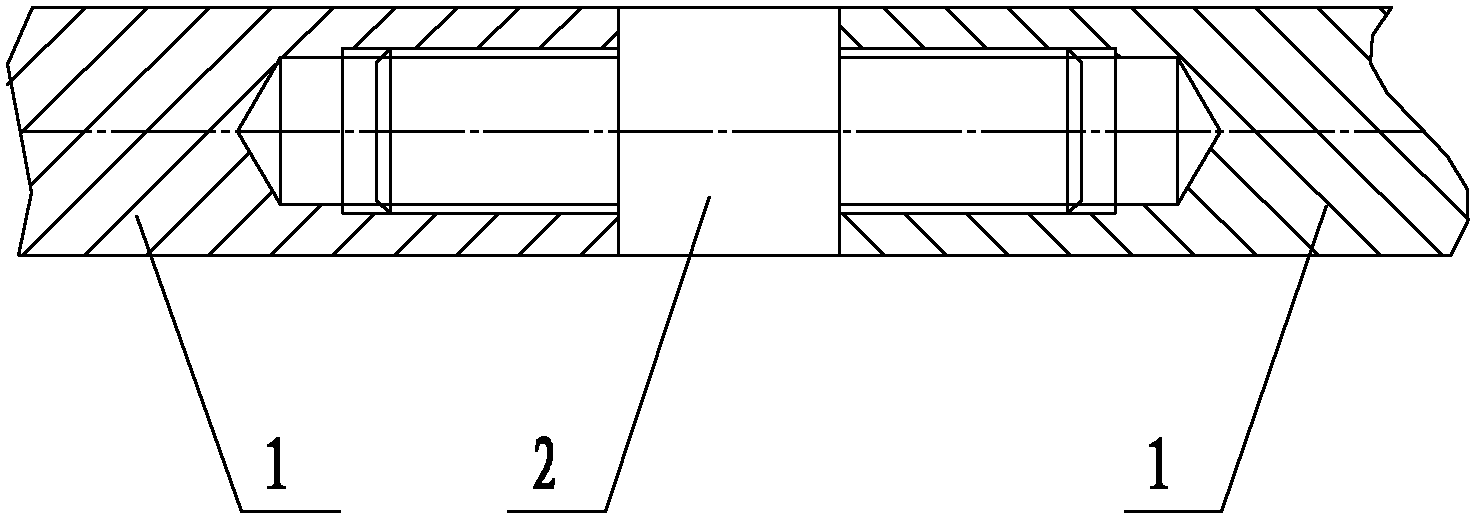

[0011] Such as figure 1 As shown, the present invention includes two recovery shafts 1 and a connecting shaft 2, the two ends of the connecting shaft 2 are provided with threaded shaft heads, one end of the recovery shaft 2 is provided with a threaded hole, and the two recovery shafts 1 and the two The connecting shaft 2 is screwed into one body.

[0012] The recovery shaft 1 is consistent with the maximum diameter of the connection shaft 2 .

[0013] After the recovery shaft 1 is screwed to the connection shaft 2, further welding is performed at the joint for fixing.

[0014] When installing, the connecting shaft 2 is first screwed with one of the recovery shafts 1, and then screwed with the other recovery shaft 1. After the recovery shaft 1 and the connecting shaft 2 are screwed together, the outer circle is welded to make it a whole. Increase the strength and rigidity, and avoid the twisting of the recovery shaft caused by the torque generated by the rotation.

[0015] A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com