Visual navigation system of wall climbing robot for weld inspection, welding and locating method of welding seam and method of obtaining welding seam offset

A technology of wall-climbing robot and visual navigation, which is applied in the directions of surveying and mapping, navigation, navigation, measuring device, etc., can solve the problem of inability to realize the maintenance work of the tower.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

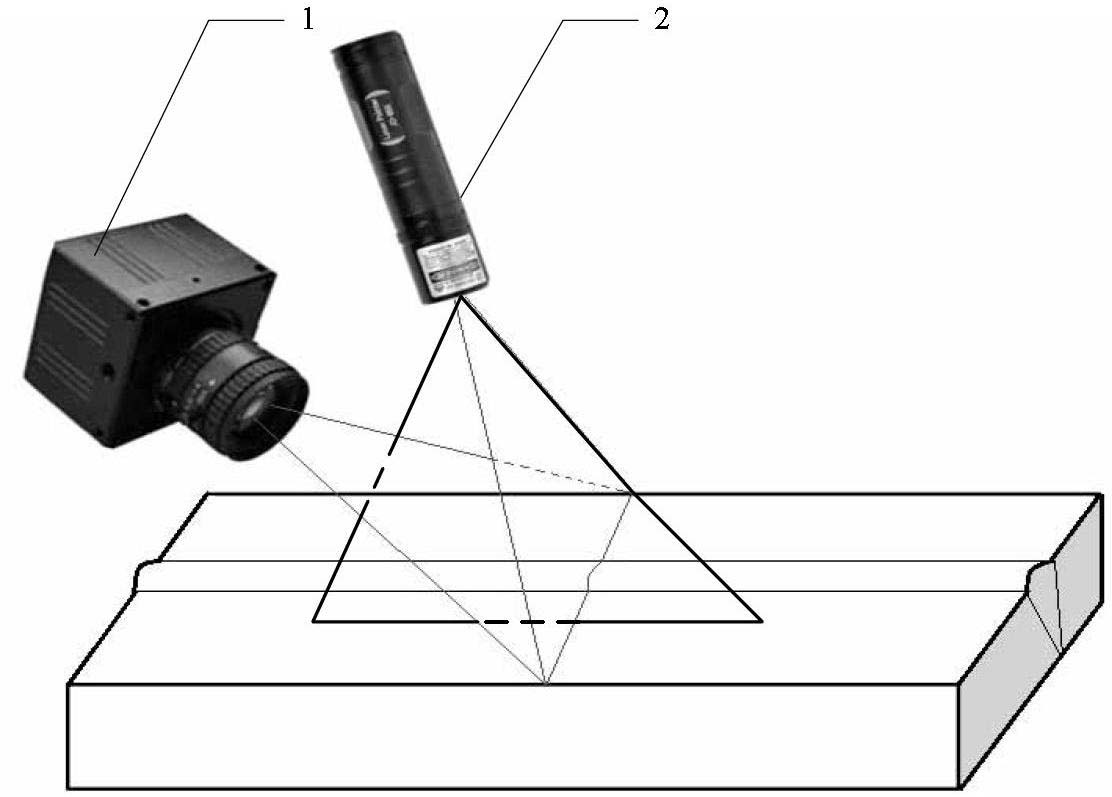

[0024] Specific implementation mode 1. Combination figure 1 Describe this embodiment in detail, the visual navigation system of the wall-climbing robot that is used for welding seam detection described in this embodiment, it comprises charge-coupled camera 1, cross laser emitter 2 and computer,

[0025] The charge-coupled camera 1 and the cross laser emitter 2 are fixed on the front end of the robot head, and the cross laser emitter 2 is directly above the charge-coupled camera 1, and the laser emitted by the cross laser emitter 2 is irradiated on the workpiece to be welded A cross spot is formed on the surface, and the charge-coupled camera 1 is used to photograph the cross spot on the workpiece surface, and the angle between the optical axis of the laser beam emitted by the cross laser emitter 2 and the optical axis of the camera head of the charge-coupled camera 1 is 45°, and the charge-coupled The data output end of the camera 1 is connected with the data input end of the ...

specific Embodiment approach 2

[0026] Specific embodiment two, based on the welding positioning method of the weld seam of the visual navigation system of the wall-climbing robot that is used for weld seam detection described in specific embodiment one, it comprises the following steps:

[0027] Step 1. The cross laser transmitter 2 emits a red cross-shaped laser beam. The laser beam is irradiated on the surface of the workpiece to be welded to form a cross spot, and the laser beam is used to scan the surface of the workpiece. During the scanning process, the charge-coupled camera 1 is used to collect For the video information on the surface of the workpiece, perform step 2;

[0028] Step 2, the computer receives the video information collected by the charge-coupled camera;

[0029] Step 3, the computer processes each frame of image in the video information as follows:

[0030] Step 31, dividing the frame image into pixels, the values of the pixels represent the values of the red, yellow and blue color...

specific Embodiment approach 3

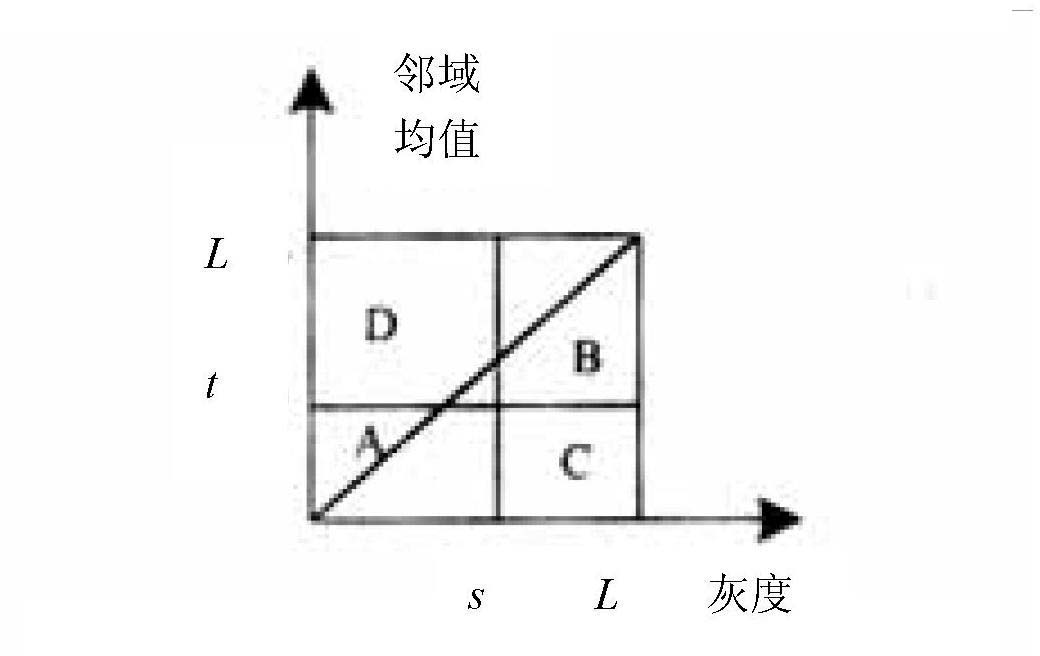

[0042] Specific embodiment three, combine figure 2 This embodiment is described in detail. The difference between this embodiment and the second embodiment is that the optimal threshold method for obtaining the gray value corresponding to the value of the red component described in step 33 is:

[0043] The four pixels on the top, bottom, left, and right adjacent to a pixel on the image and its four diagonal adjacent pixels constitute the neighborhood information of the eight pixels of the pixel, and the image is obtained by the two-dimensional maximum entropy segmentation method. The two-dimensional histogram of the point gray value and the gray value of the neighborhood information gray value of the pixel point, using the maximum two-dimensional entropy to obtain the optimal threshold f(x, y) of the gray value corresponding to the red component value;

[0044] Among them, (x, y) is the coordinate of the pixel point,

[0045]The A and B areas of the two-dimensional histogram...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com