Asphalt mixture fatigue test method based on DCT (Disk-Shaped Compact Tension) and HD (High Definition) imaging technology

An asphalt mixture and fatigue test technology, which is applied in the field of asphalt mixture fatigue test and asphalt mixture fatigue performance test field, can solve the problems of long cycle, cumbersome experimental process and high cost, and achieve good fatigue performance, convenient preparation and cost. reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

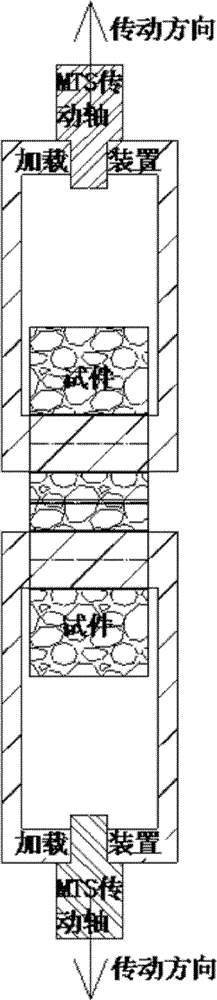

[0023] This embodiment provides an asphalt mixture fatigue test method based on DCT and high-definition image technology. The specific test process is as follows:

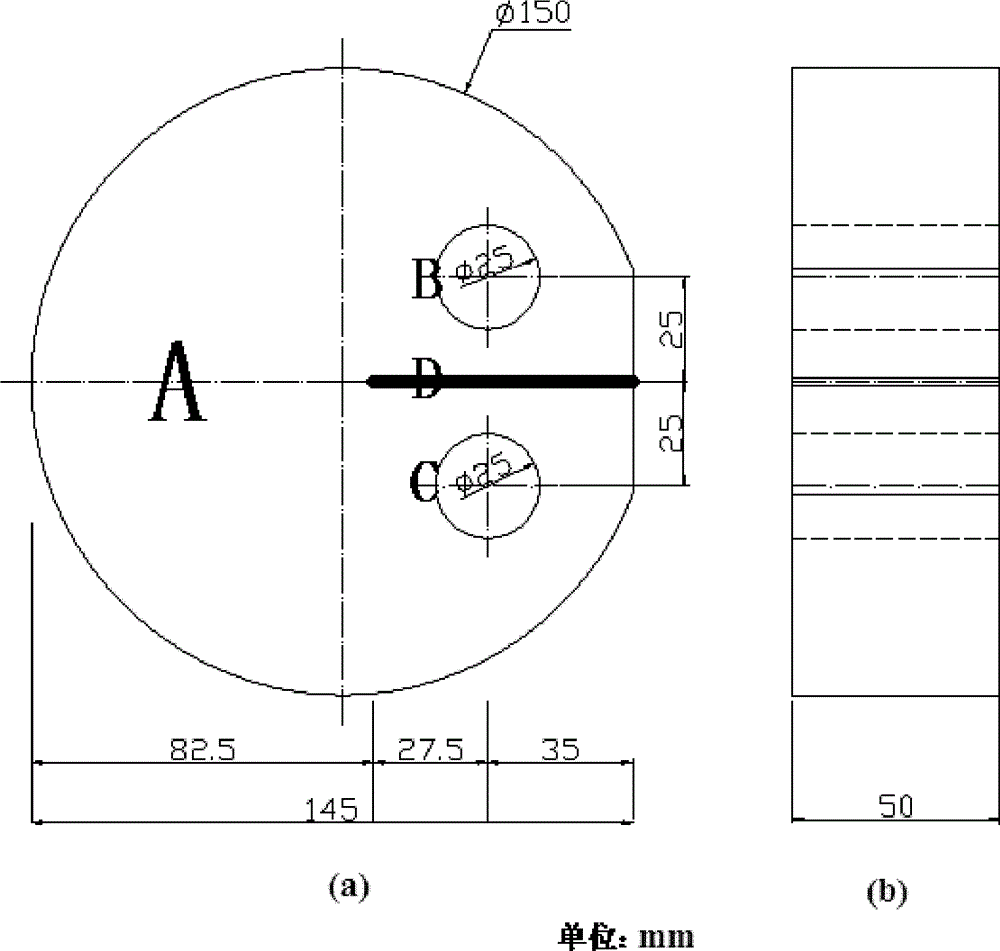

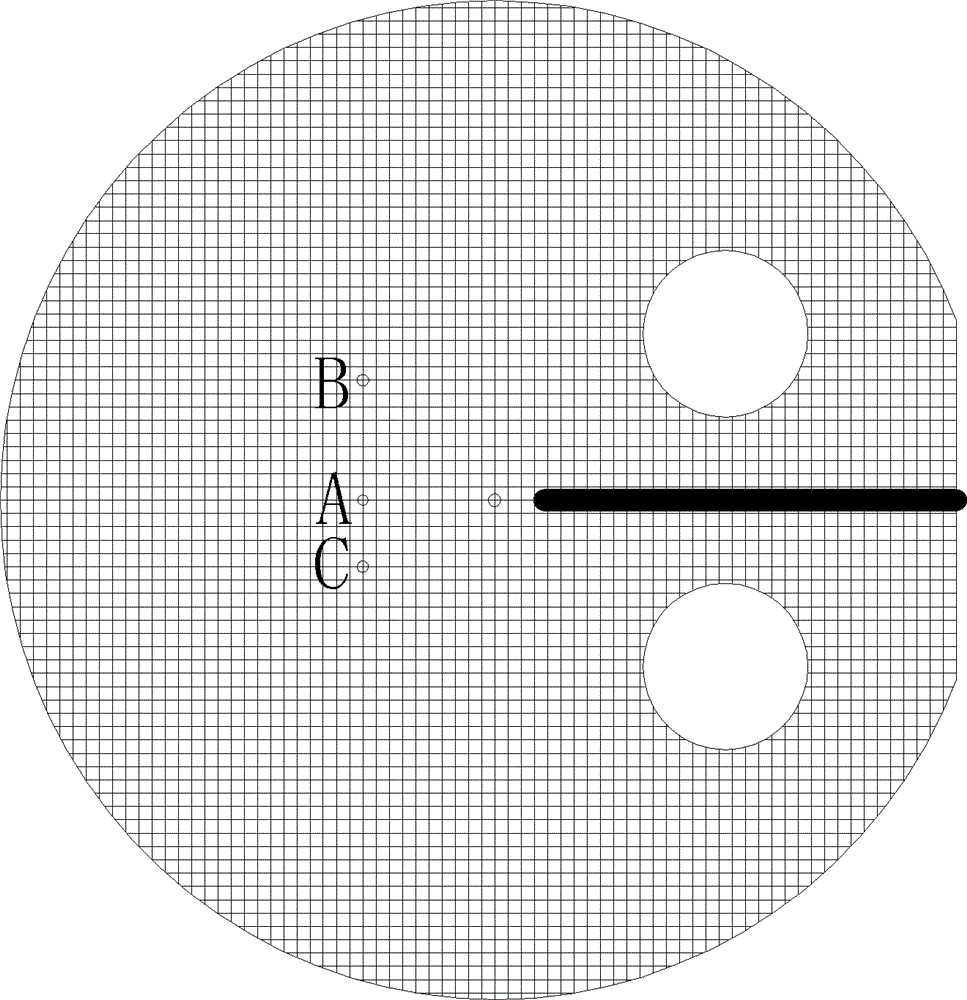

[0024] 1. Prepare the test piece according to the relevant technical requirements of ASTM-D7313-07a. For specific specifications, see figure 1 shown. In the figure, A represents the whole test piece, B and C represent the pre-drilled holes in the test piece, and D represents the pre-cut slit. Test pieces can be either laboratory formed (rotary compaction) or field cored. The entire size should be set strictly according to the requirements. In general, a formed specimen can be prepared into several specimens meeting the experimental requirements by cutting, so sample preparation is more convenient.

[0025] see figure 1 , the test piece is a circular block with a thickness of 50 mm and a diameter of 150 mm, wherein, one end of the circular block is cut off by 5 mm, and the center line of the circular block is cu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com