Flow corrosion testing device under axial fatigue load of scaling marine pipeline

A technology of flow corrosion and test device, applied in the direction of measuring device, weather resistance/light resistance/corrosion resistance, and testing material strength by applying repetitive force/pulsation force, etc. Behavior research and other issues to achieve the effect of meeting the test comparison requirements and the device is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

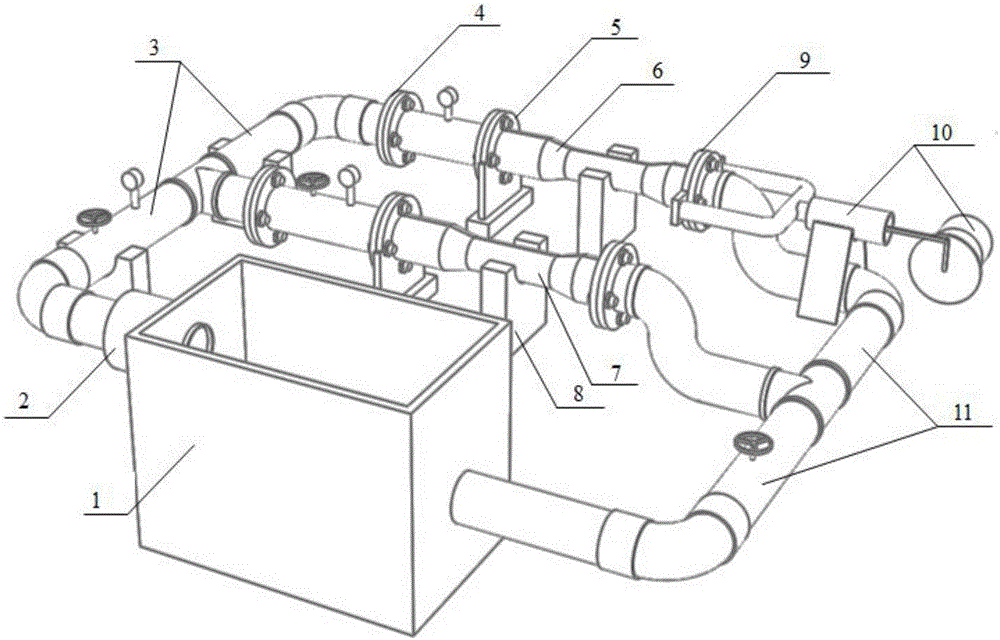

[0028] like figure 1 As shown, the flow corrosion test device of the scale marine pipeline under the axial tension and compression fatigue load mainly includes: water tank 1, speed regulating water pump 2, fluid input pipe section 3, flange 4, fixed support flange 5, load test pipe fitting 6 , Control test pipe fitting 7, pipe support 8, bearing flange 9, axial tension and compression load application device 10, fluid output pipe section 11. One end of the fluid input pipe section 3 and the fluid output pipe section 11 communicate with the water tank 1, and the other end is connected with the test pipe fitting by a flange to form a fluid passage in the pipe. The test fluid in the water tank 1 is exchanged according to the test requirements. The speed-regulating water pump 2 controls the flow rate of the fluid entering the fluid input pipe section 3 from the water pump. The test fluid enters the test pipe fittings 6 and 7 through the fluid input pipe section 3, and flows into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com