Clutch device

A clutch device and clutch technology, applied in the direction of clutches, friction clutches, mechanical drive clutches, etc., can solve problems such as the reduction of the pressing force of the pressing part 105

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038]

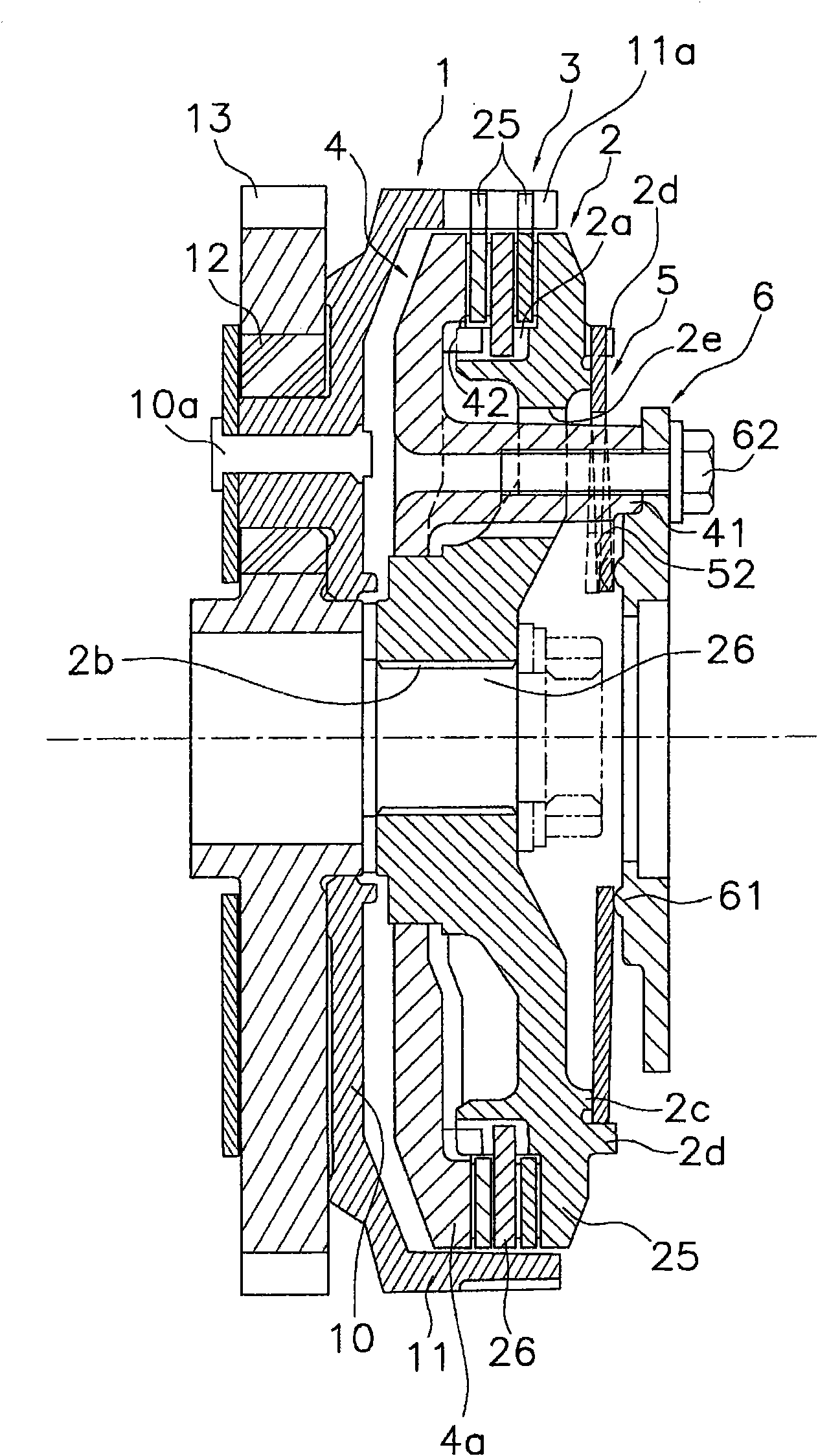

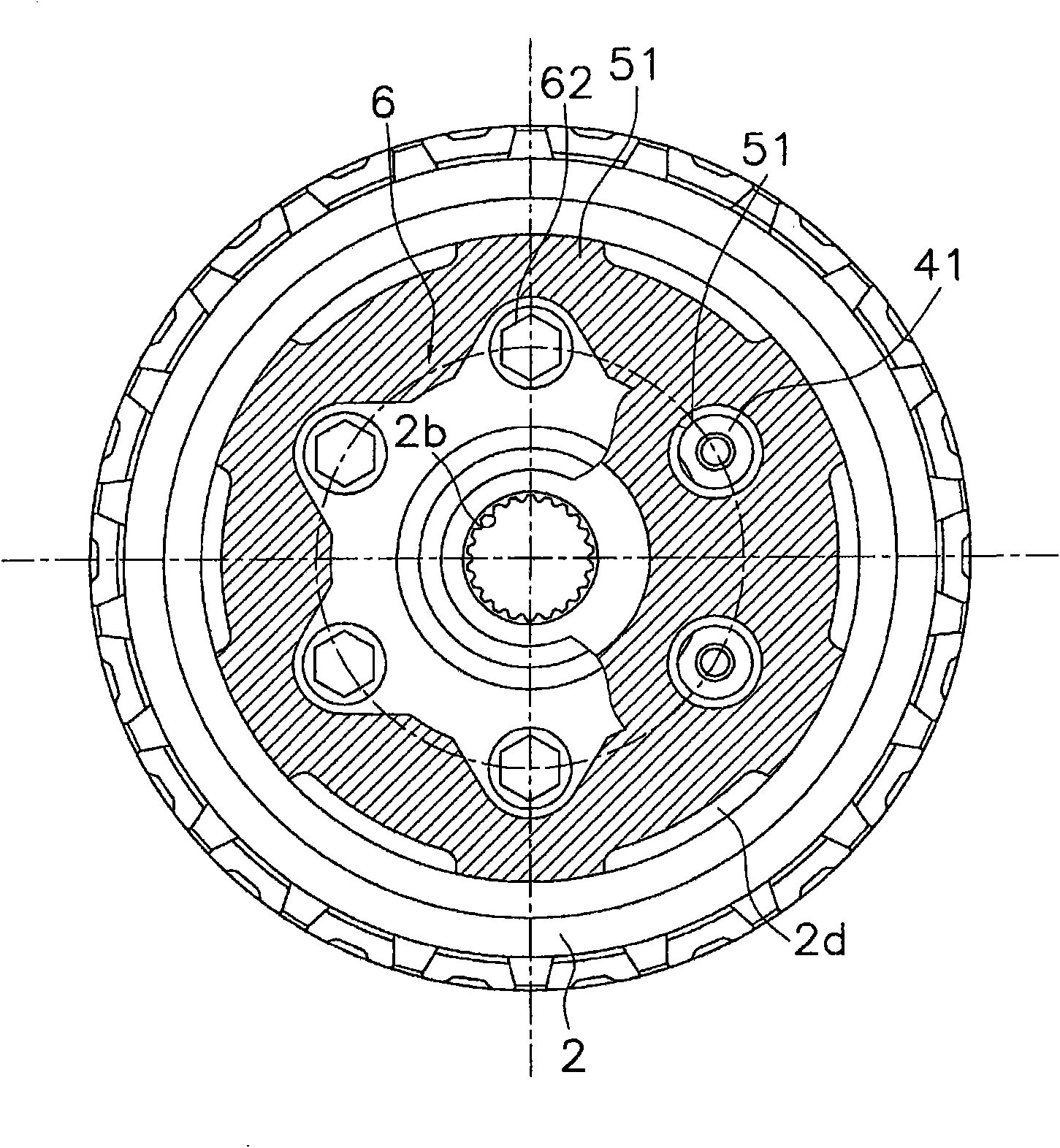

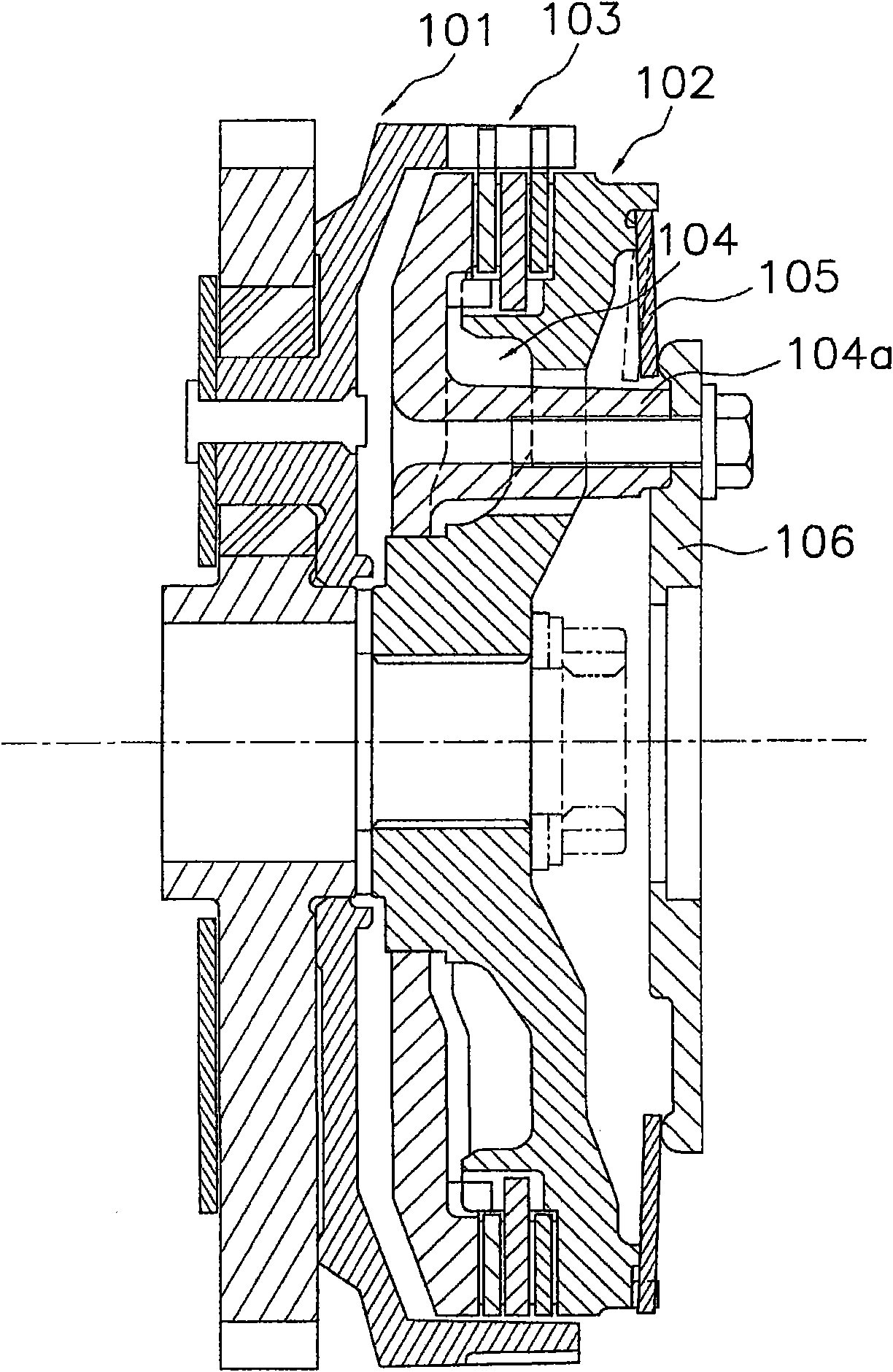

[0039] figure 1 and figure 2 The clutch device shown is a device for transmitting the power from the crankshaft of the engine to the transmission, and cutting off the power transmission by a disengagement operation. In addition, in figure 1 and figure 2 Both crankshaft and gearbox are omitted. This clutch device includes a clutch housing 1, an output side rotating body 2 (first rotating body), a clutch portion 3 for transmitting or disconnecting power between the clutch housing 1 and the output side rotating body 2, and a pressing disc member 4 ( second rotating body), diaphragm spring 5 (pressing member), and separation member 6 (disk-shaped member). In this device, the separation member 6 is moved axially inward by the separation operation ( figure 1 left in ) to cut off the power transmission.

[0040]

[0041] The clutch housing 1 is on one direction side of the axial direction ( figure 1on the right side) has an opening, and includes a disk porti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com