Digital adjustable microinjection method

A syringe and adjustable technology, applied in the field of syringes, can solve the problems of large tissue damage, blockage of syringe needles, and increase the operational complexity of traditional micro-injection methods, and achieve the effects of convenient injection volume and convenient control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

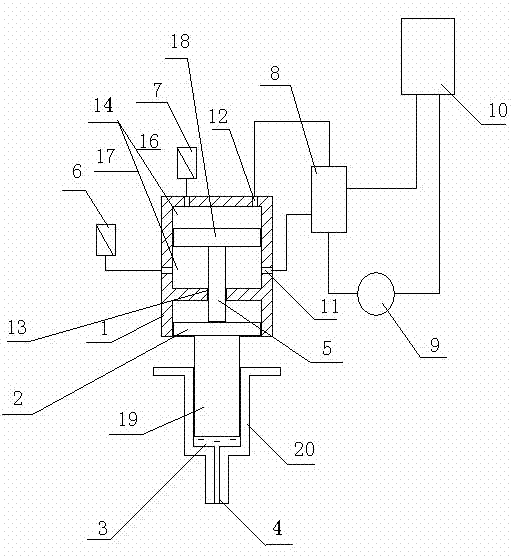

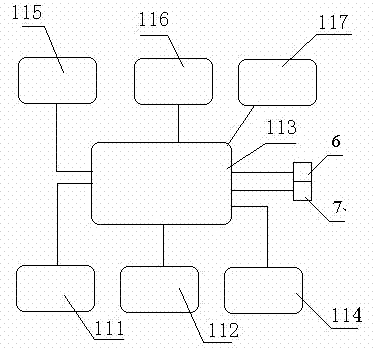

[0017] Such as figure 1 As shown, a digital adjustable micro-injection method at least includes a tube body, the tube body is composed of a piston tube body 1 and a syringe tube body 20, the lower end of the syringe tube body 20 is the syringe liquid outlet 4, and the piston chamber of the piston tube body 1 The chamber 14 is divided into an upper chamber 16 and a lower chamber 17 by a piston 18, and the upper chamber 16 and the lower chamber 17 have an air input / output port 11 and an air output / input port 12 respectively. The gas input / output port 11 can be the gas input port or the gas output port; similarly, the gas output / input port 12 can be the gas output port or the gas input port; the lower end of the syringe piston 2 extends into the syringe tube The injection chamber 3 of the body 20, the injection chamber 3 sucks the injection through the syringe outlet 4; the upper chamber 16 has a pressure sensor interface, and the pressure sensor 7 is connected through the pressu...

Embodiment 2

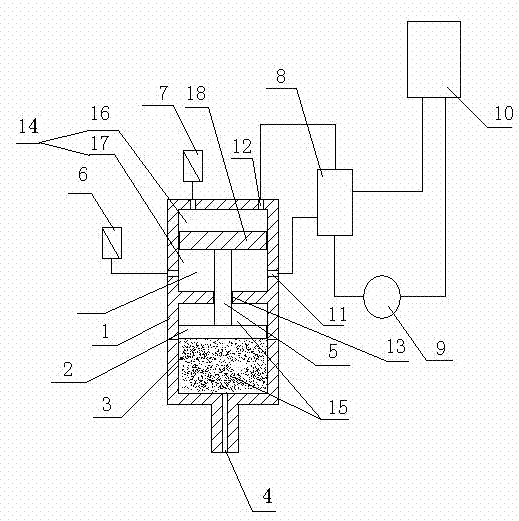

[0021] Such as image 3 As shown, a digitally adjustable micro-injector at least includes a tube body, the tube body is composed of a piston tube body 1 and a syringe tube body 20, the piston tube body 1 and the syringe tube body 20 are an integrated tube body structure, and the tube body is composed of a sealing port 13 is divided into a piston chamber 14 and an injection chamber 15, the lower end of the injection chamber 15 is the syringe outlet 4, the piston chamber 14 is divided into an upper chamber 16 and a lower chamber 17 by a piston 18, and the upper chamber 16 and the lower chamber The cavity 17 has an air input / output port 11 and an air output / input port 12 respectively. The gas input / output port 11 can be the gas input port or the gas output port; similarly, the gas output / input port 12 can be the gas output port or the gas input port; the injection chamber 15 has Syringe piston 2, the injection liquid chamber 3 is formed at the lower end of the syringe piston 2, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com