Dual-gear oil pump

A duplex gear and oil pump technology, applied in the direction of pumps, pump components, rotary piston pumps, etc., can solve the problem of increasing the radial force, coaxiality and position accuracy of the front driving gear and the rear driving gear, and the difficulty in positioning Problems such as the large shape of each part of the pin hole can reduce the radial force, improve the volumetric efficiency and service life, and achieve the effect of compact shape and size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

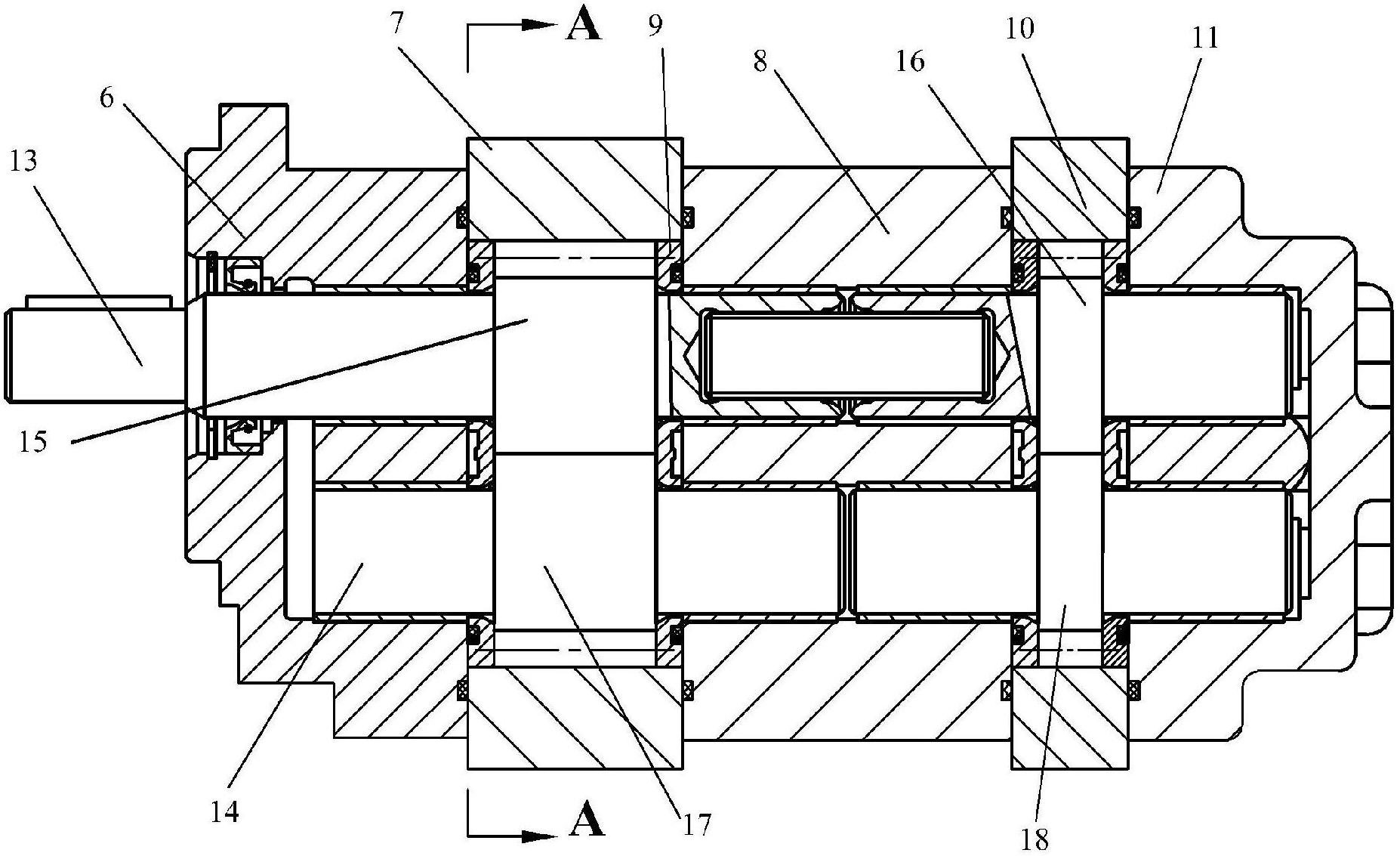

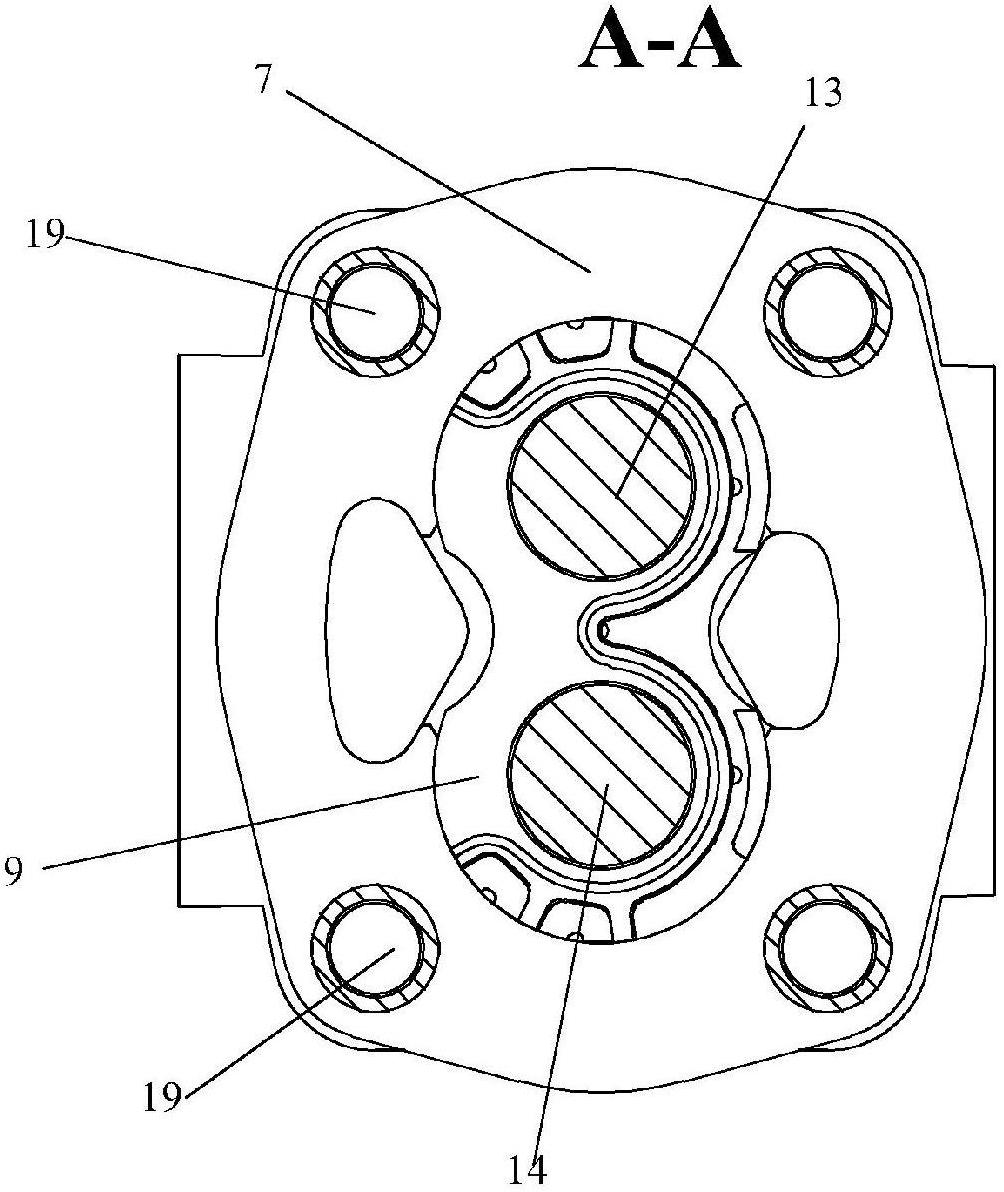

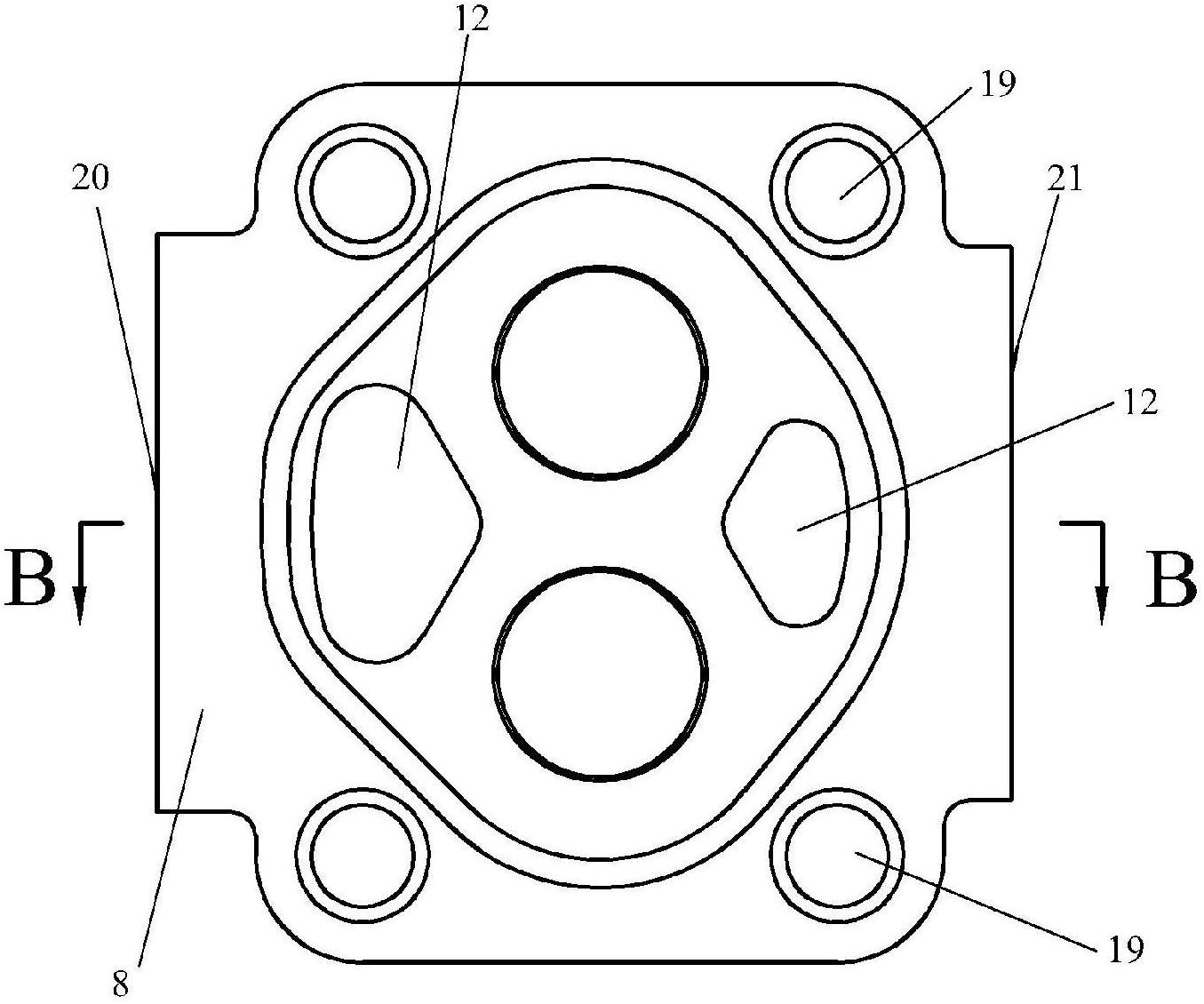

[0030] see attached picture figure 1 ~ attached Figure 8 , a double gear oil pump, including an oil pump body, a gear shaft and a gear; the gear shaft is arranged in the cavity of the oil pump body, and the gear is sleeved on the gear shaft; the oil pump body includes a front cover 6, Front pump body 7, connecting plate 8, side plate 9, rear pump body 10 and rear cover 11, the front cover 6, front pump body 7, connecting plate 8, rear pump body 10 and rear cover 11 are in order from left to right Set, the side plate 9 is located in the inner cavity of the front pump body 7 and the rear pump body 10; the gear shaft includes a driving gear shaft 13 and a driven gear shaft 14; the gear includes a front driving gear 15, a rear driving gear Gear 16, front driven gear 17 and rear driven gear 18; said front driving gear 15 and front driven gear 17 are meshed, and two side plates 9 are respectively positioned at said front driving gear 15 and front driven gear 17 Both sides; the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com