Flat-screen developing machine

A developing machine and flat screen technology, which is applied in printing, printing plate preparation, photosensitive material processing, etc., can solve the problems of slow developing speed, insufficient uniformity, low production efficiency, etc., and achieve high developing speed, uniform developing effect, The effect of increasing the porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

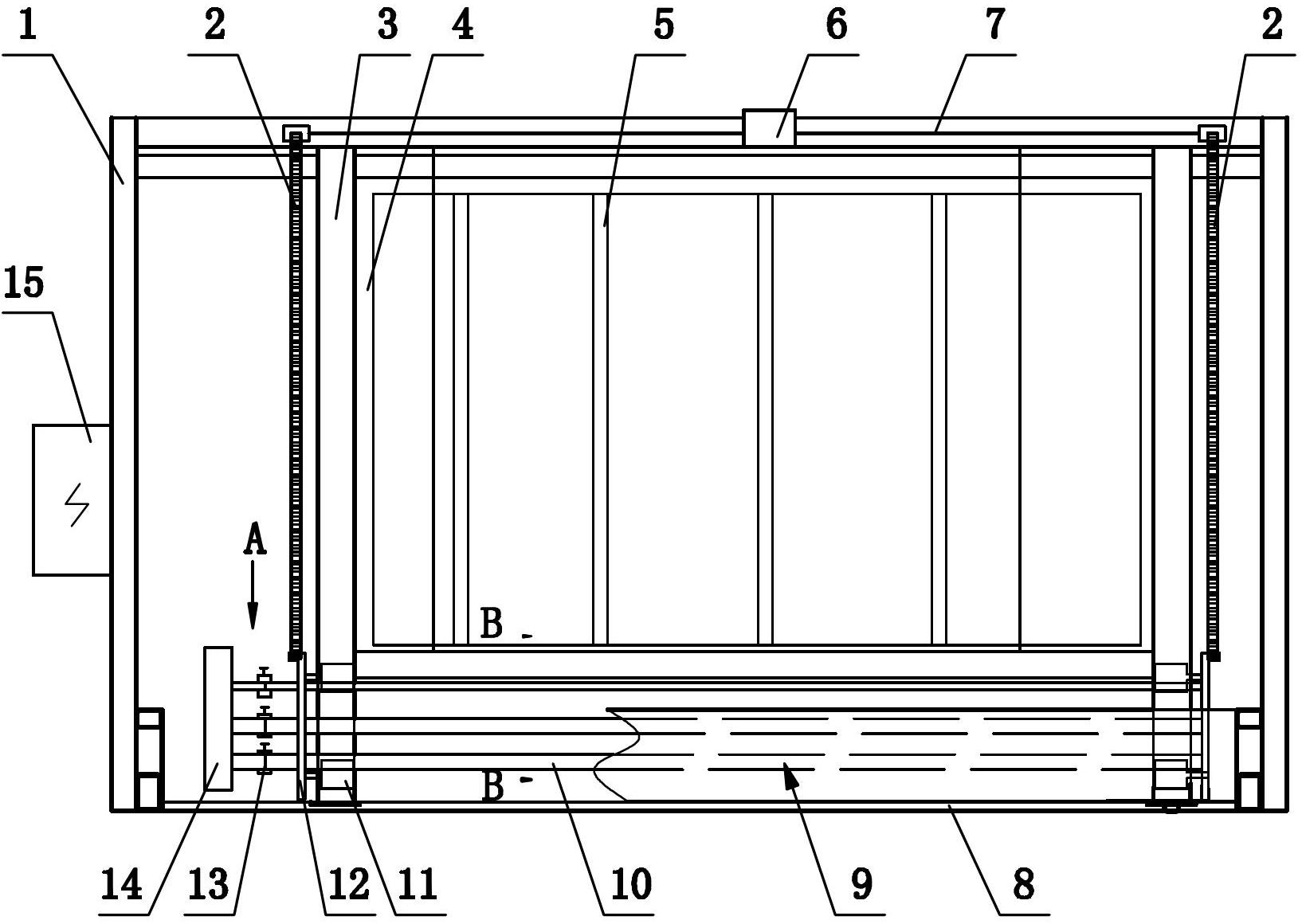

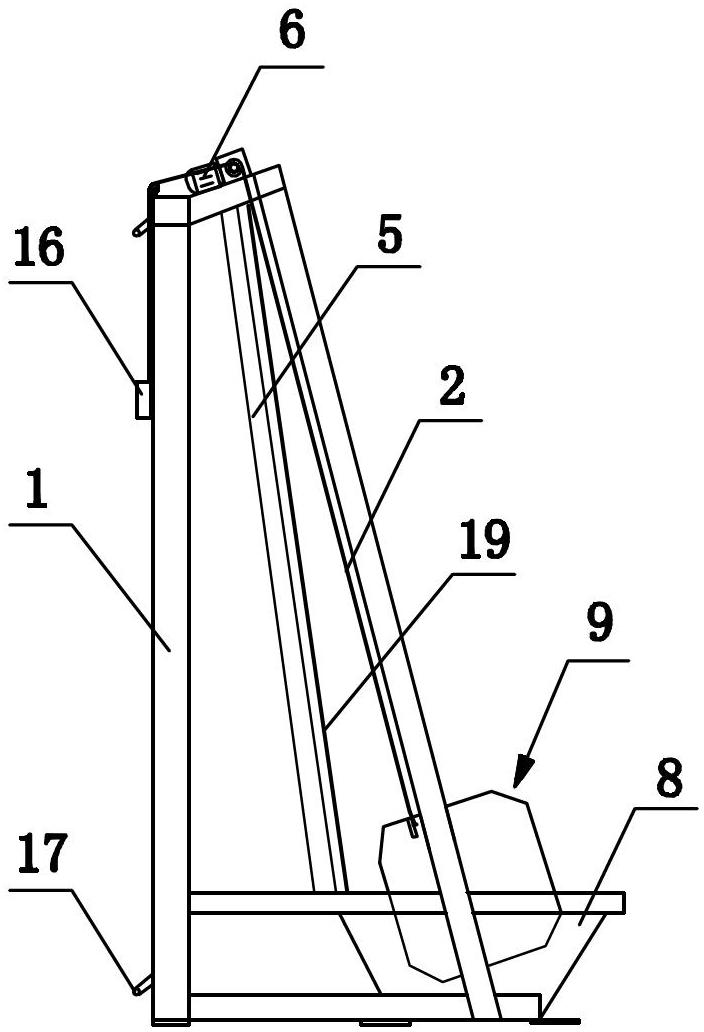

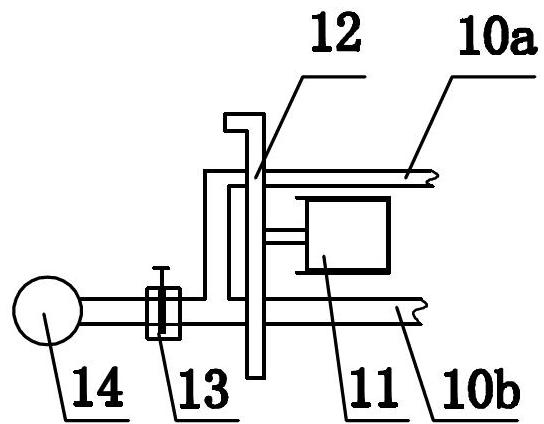

[0023] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown together, it is an embodiment of the flat screen developing machine of the present invention. The flat screen developing machine includes: a frame 1, the bottom of the frame 1 is provided with a water collection tank 8; the frame 1 is obliquely provided with a screen frame seat 4 Be provided with illuminating device 5 at the back of screen frame seat 4, in the present embodiment, illuminating device 5 is the lamp tube that a plurality of intervals are arranged; Openings are respectively arranged at the bottom and the bottom, and the developing car 9 is set on the screen frame seat 4 through these two openings, and can be reciprocated up and down by the power device. The two ends of the cylindrical car body are closed by end plates 12 respectively. There is a spray device in the body.

[0024] In the present embodiment, the above-mentioned spraying device includes three groups of nozzles arranged up and d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com