Welding process of non-contact intelligent card antenna

A non-contact smart card, welding process technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of easy to touch the chip, difficult to ensure the accurate position of the antenna, manually dialing the chip and other problems. The effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A non-contact smart card antenna welding process, which includes the following sequential steps:

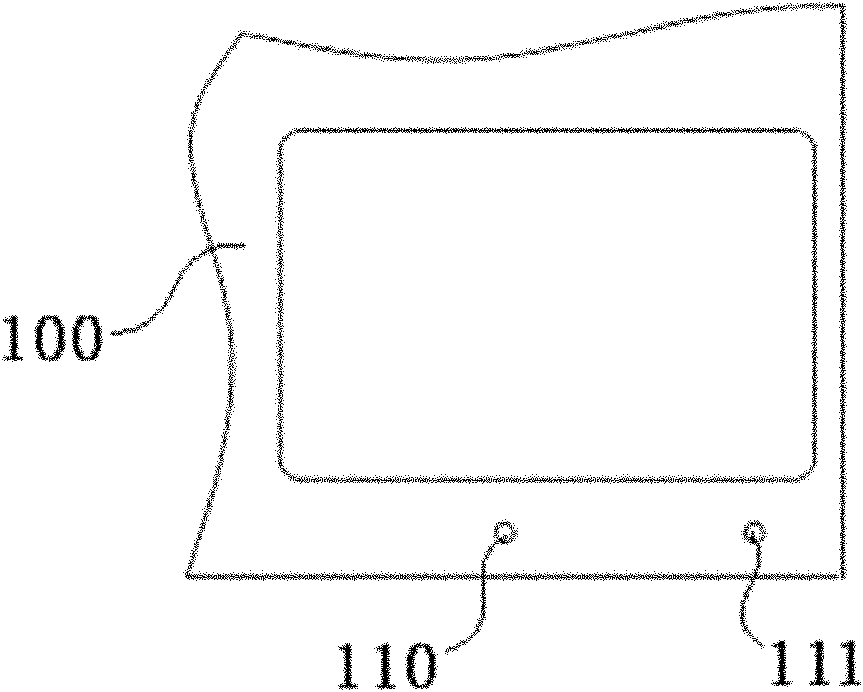

[0039] (1) see figure 1 . Two positioning holes 110, 111 for positioning in the X and Y directions are punched out on a single-layer card base material 100. The positioning holes 110 are used for the positioning of each material during the processing of each process. Of course, it can also be carried out directly with the edge of the material The positioning of each process or stamping any other positioning structures known to those skilled in the art.

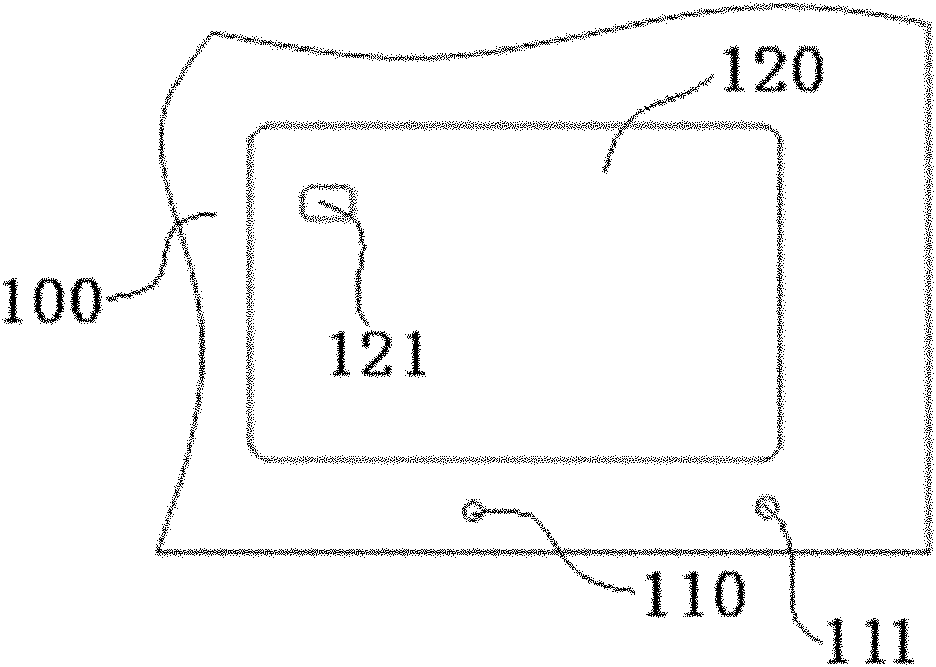

[0040] (2) see figure 2 , punch out a chip hole 121 in the card region 120 of a single-layer card base material 100; the chip hole 121 is a through hole.

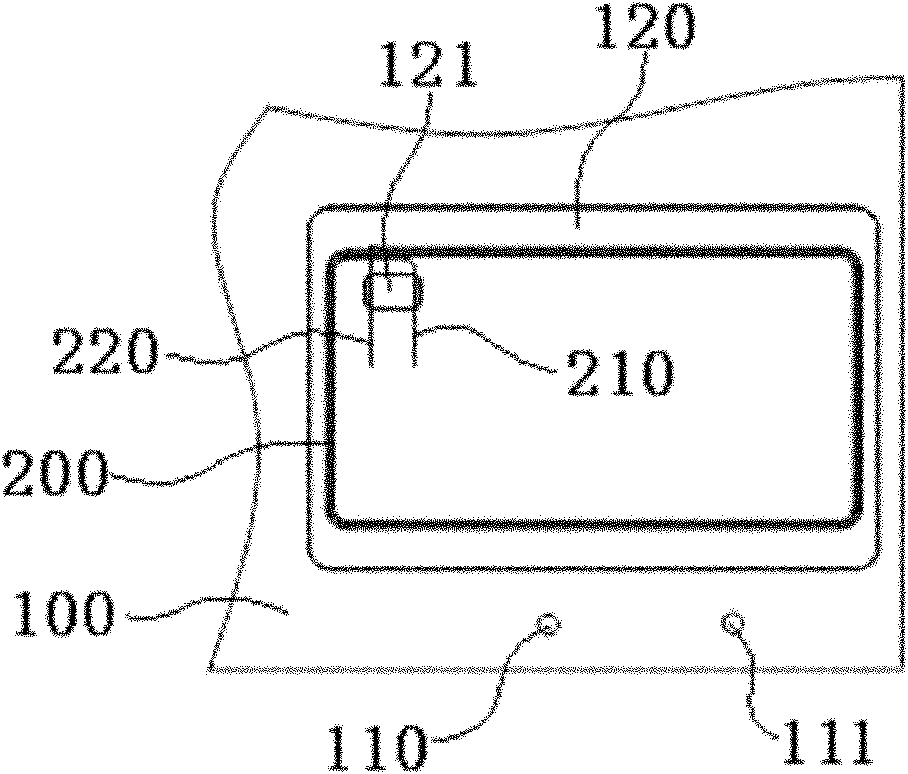

[0041] (3) see image 3 , bury the antenna 200 on the front surface of the card area 120 of the single-layer card base material 100, and the two welding ends 210, 220 of the antenna 200 straddle the chip hole 121;

[0042] (4) see Figure 4 , the chip 300 is fill...

Embodiment 2

[0045] The steps of this embodiment are the same as in Example 1, see Figure 7 , but in step (4), the black glue part 310 of the chip 300 faces the back of the card area 120 .

Embodiment 3

[0047] A non-contact smart card antenna welding process, which includes the following sequential steps:

[0048] (1) see Figure 8 , two positioning holes 110a, 111a for positioning in the X and Y directions are respectively punched on the single-layer card base material 100a, see Figure 9 Two positioning holes 100b, 111b for positioning in the X and Y directions are respectively punched on the single-layer card base material 100b. The positioning holes 110a, 111a, 100b, and 111b are used for the positioning of each material during the processing of each process. Directly use the edge to carry out the positioning of each process or punch any other positioning structures known to those skilled in the art.

[0049] (2) see Figure 10 with Figure 11 , chip holes 121a, 121b are respectively punched out in the card areas 120a, 120b of the two single-layer card base materials 100a, 100b; and single-layer upline card base material B

[0050] (3) see Figure 12 , bury the ante...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com