Clean room

A technology of clean room and clean area, applied in the field of clean room, can solve the problems of large air circulation, differential temperature distribution, etc., and achieve the effect of simple leakage test

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

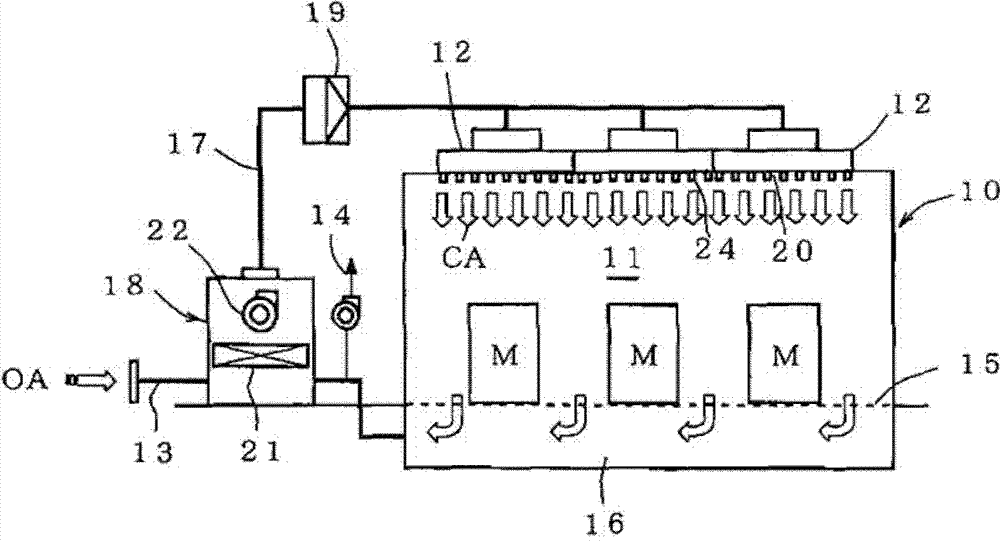

[0036] A preferred embodiment of the present invention will be described in detail below based on the drawings.

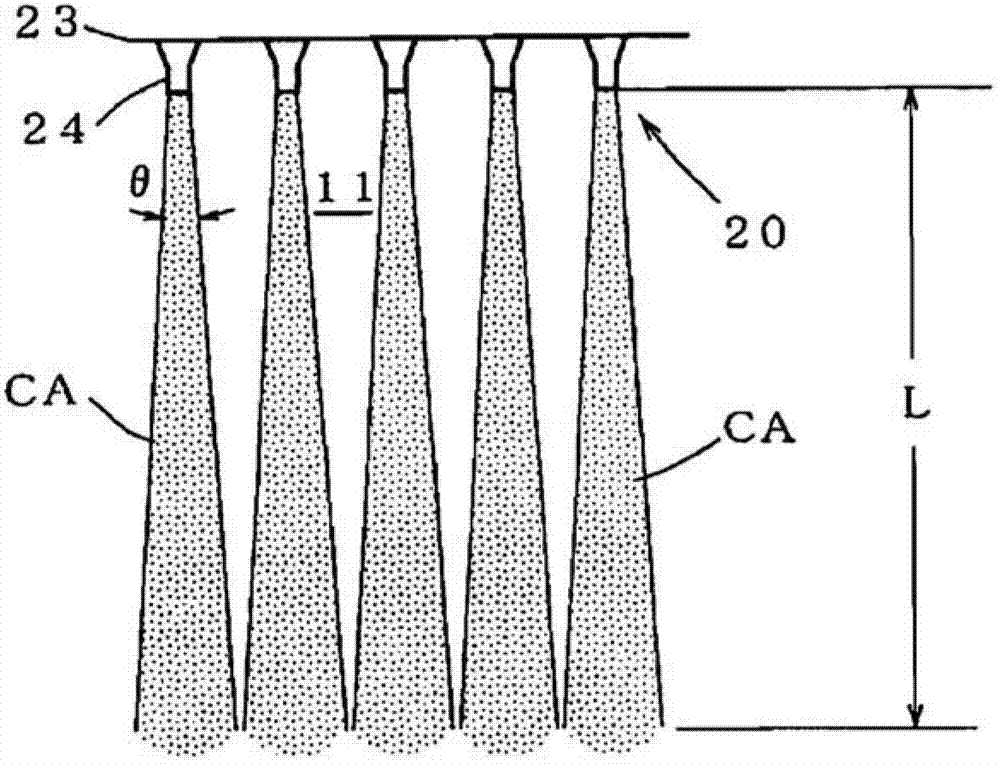

[0037] figure 1 An overall view showing the clean room of the present invention.

[0038] First, the clean room 10 is configured such that a plurality of air supply chambers 12 are arranged adjacent to each other over substantially the entire surface of the ceiling of the clean area 11 where the manufacturing equipment M is installed. The return chamber 16 connects the return chamber 16 and the air supply chamber 12 to a circulation path 17 , and the circulation path 17 is connected to an air conditioner 18 .

[0039] In the present embodiment, a high-performance filter (HEPA or ULPA) 19 is provided on the circulation path 17, and a plurality of flat nozzles 20 are provided at the opening of the air supply chamber 12 to form a discharge port.

[0040] The air conditioner 18 has an evaporator 21 and a circulation fan 22, an introduction line 13 of outside air OA ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com