Fastening device for quickly assembled concrete formwork

A concrete formwork and quick-installation technology, which is applied in the field of concrete formwork components, can solve problems such as inconvenient operation and low efficiency, and achieve the effects of improving versatility, good snap connection, and convenient assembly operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

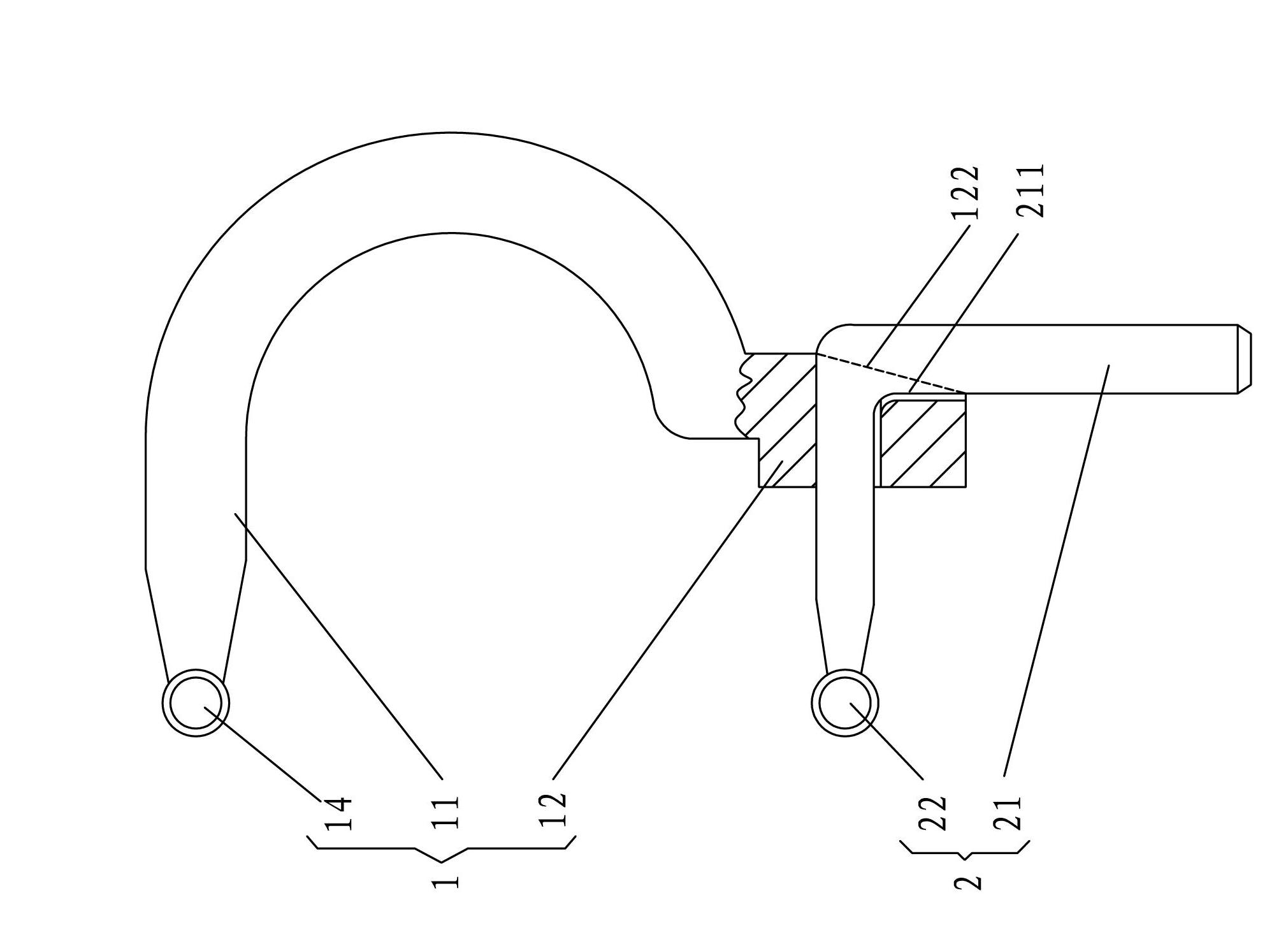

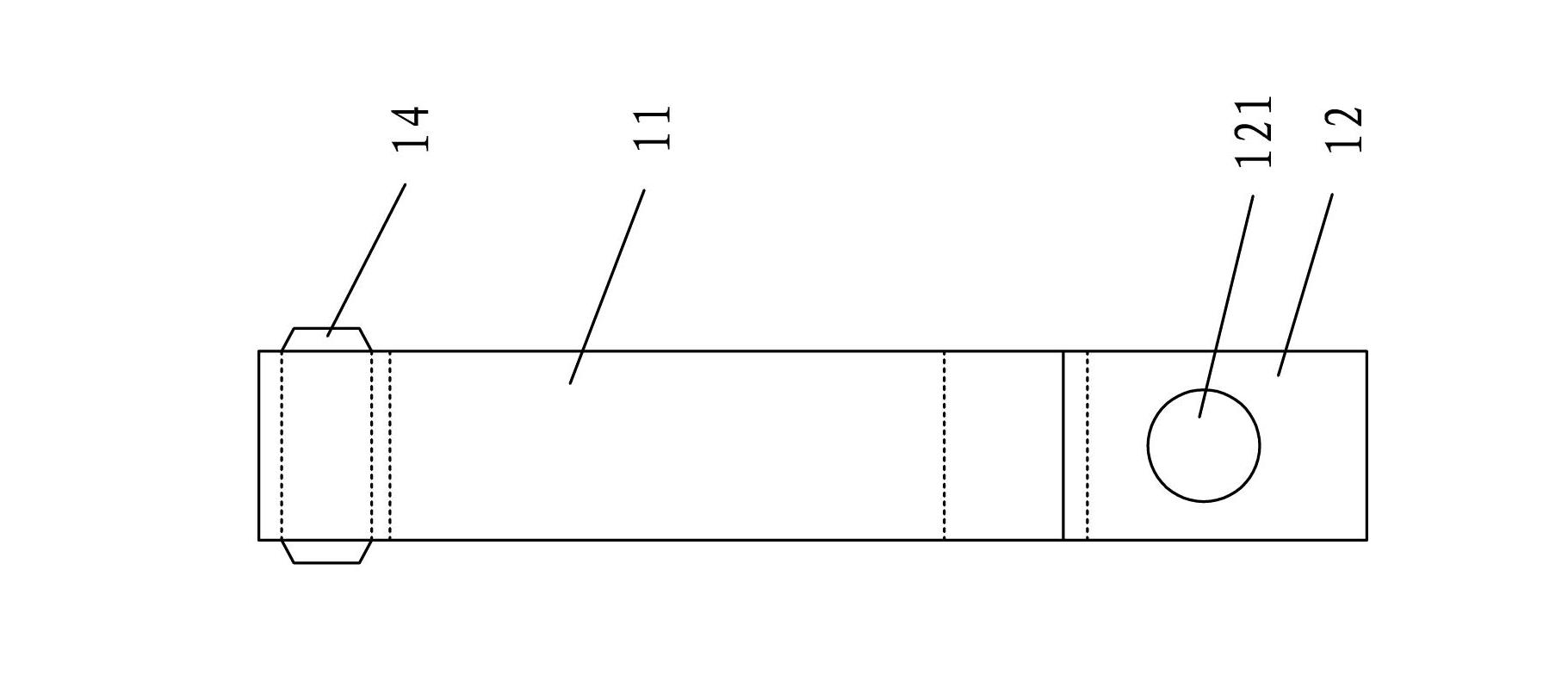

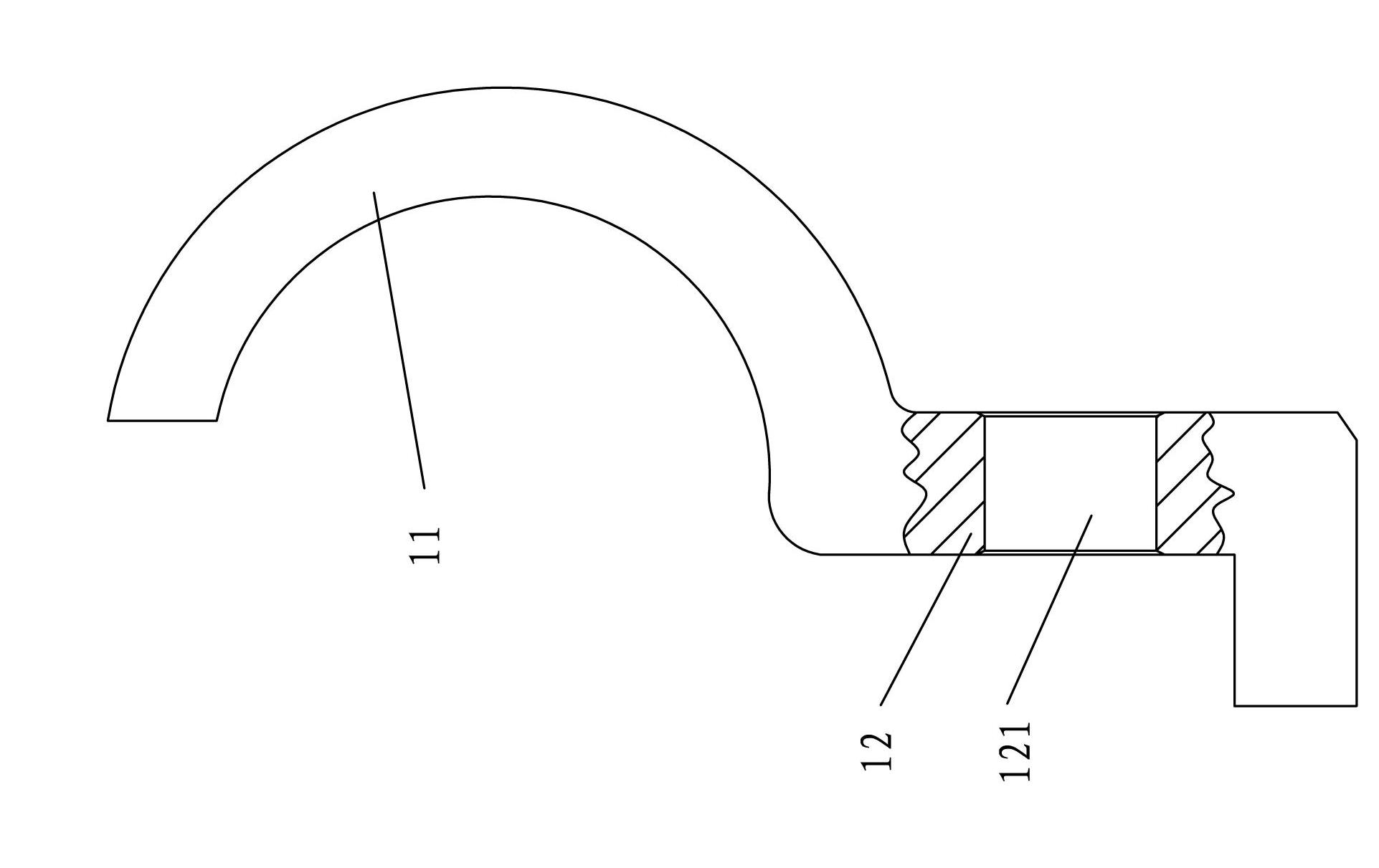

[0063] A snap-fastening structure is adopted between the lock 2 and the concrete template. The lock member 2 includes a lock rod 21 inserted in the through hole 121 of the fastener 1, and a lock pin 22 provided on the lock rod 21 and buckled on the concrete form 1a. The lock pin 22 is arranged at one end of the lock rod 21, and the other end of the lock rod 21 is bent to form a pressing handle 211, which presses and abuts against the fixing base 12, and the fixing base 12 has a pressing and abutting contact with the pressing handle 211 The slope 122. In this embodiment, the amount of fastening is adjusted by correspondingly provided slope 122 and pressing handle 211, and the operation is simple and quick.

[0064] In addition, such as Figure 5 with Image 6 As shown, the use of the lock nut 3 can also achieve the effect of pressing and abutting. Such as Figure 5 As shown, the lock rod 21 is provided with an external thread, the lock nut 3 is matched with the lock member 2, an...

Embodiment 2

[0067] The lock 2 adopts a bolt structure, and one end of the lock 2 passes through such as image 3 After the through hole 121 on the fastener 1 is shown, it is screwed with the demolding nut embedded on the concrete form 1a, and the other end of the lock 2 is pressed against the concrete form 1a, thereby tightly installing the concrete form 1a On the fixed rod 3a.

[0068] As a preferred embodiment of the present invention, the present invention also includes a fastening adjustment member 4 for adjusting the amount of fastening. The tightening and adjusting member 4 includes an adjusting nut 41, an adjusting screw 42 and a lock pin 43 provided at the end of the adjusting screw 42. The end of the buckle 11 extends outward to form an adjusting seat 13, and rotating the adjusting nut 41 allows the adjusting screw 42 to pass It is movably installed on the adjusting seat 13 in a manner of extending and retracting.

[0069] In addition, the adjusting seat 13 may be provided with a not...

Embodiment 3

[0072] The two ends of the buckle 11 of the buckle 1 are fastened by a lock 2 respectively. Specifically, the end of the buckle 11 extends outward to form another fixing seat 12, the fixing seat 12 is provided with a through hole 121, and the other lock member 2 is inserted through the through hole 121. Since the two ends of the fastener 1 are respectively buckled in the same quick-connect groove 2a on the concrete form 1a, the stability of the assembled concrete form 1a can be improved while the rapid assembly is improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com